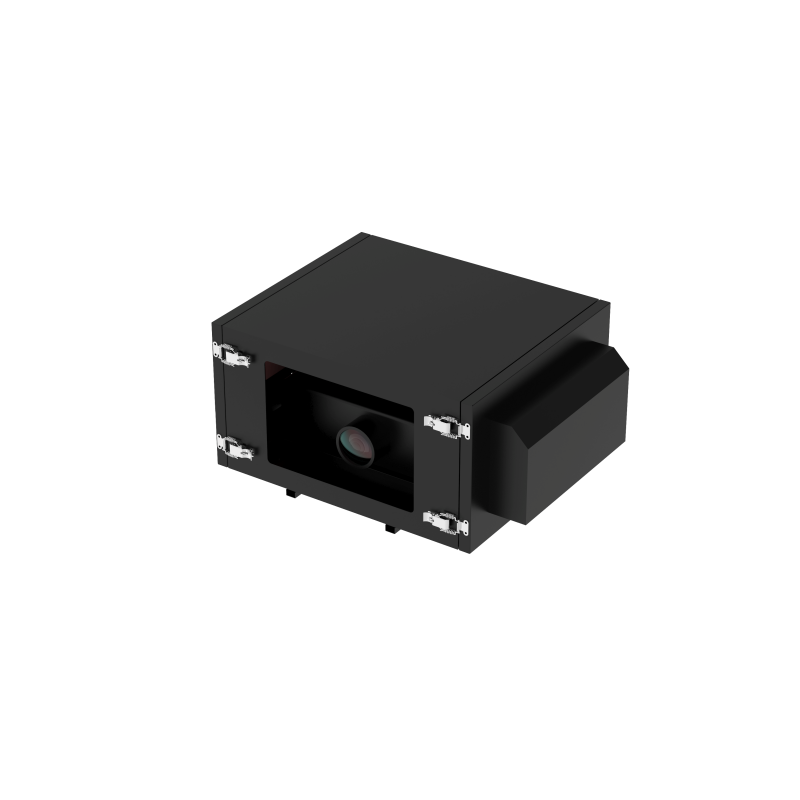

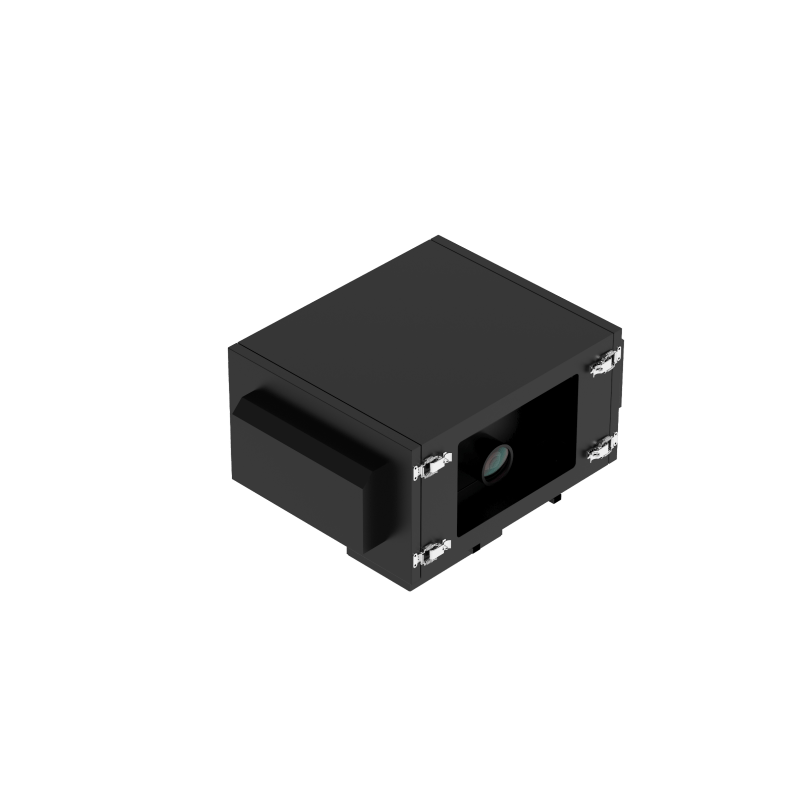

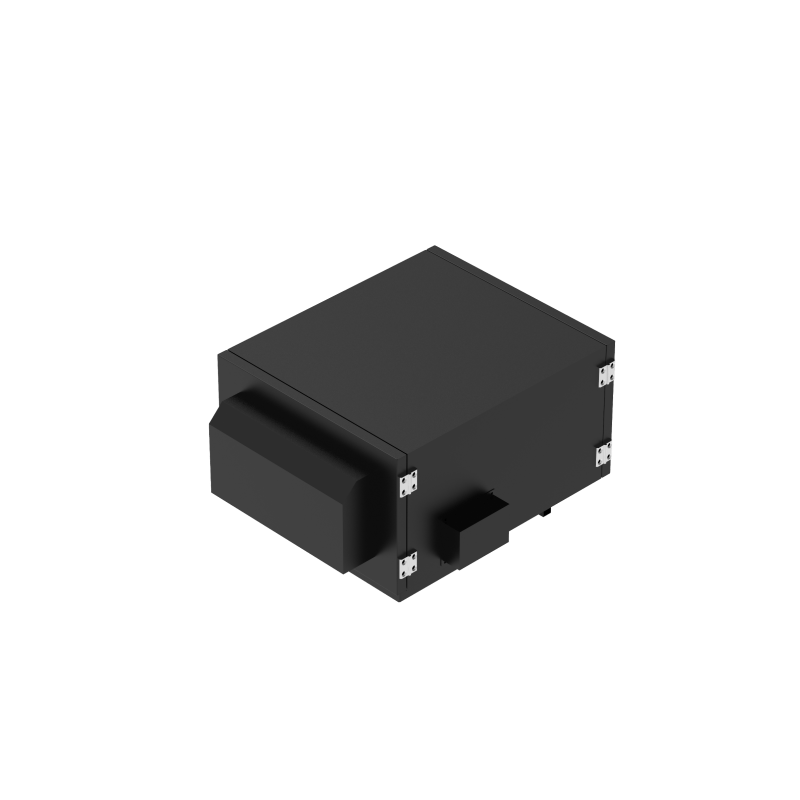

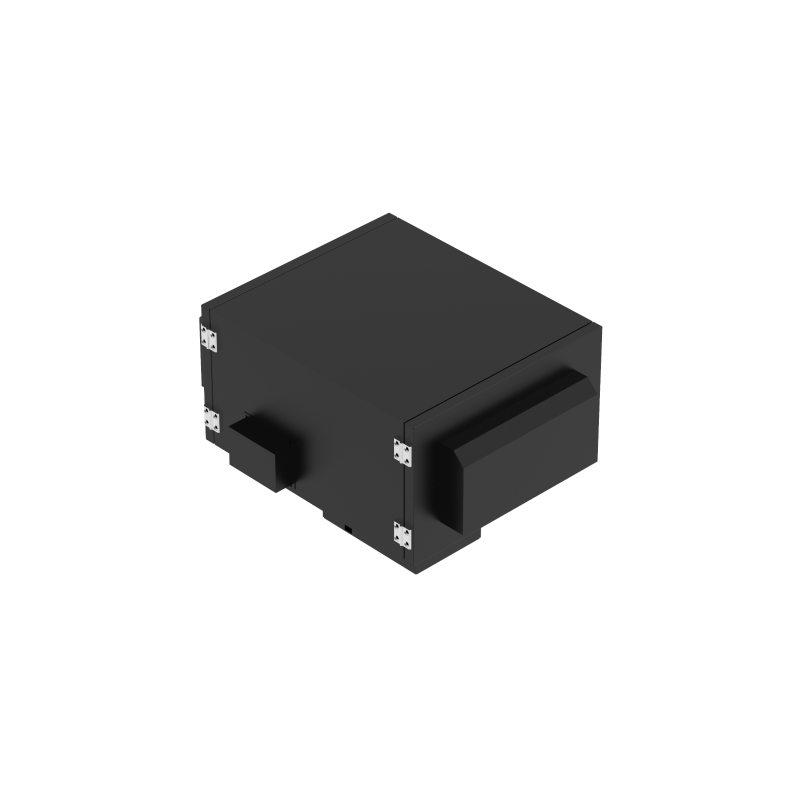

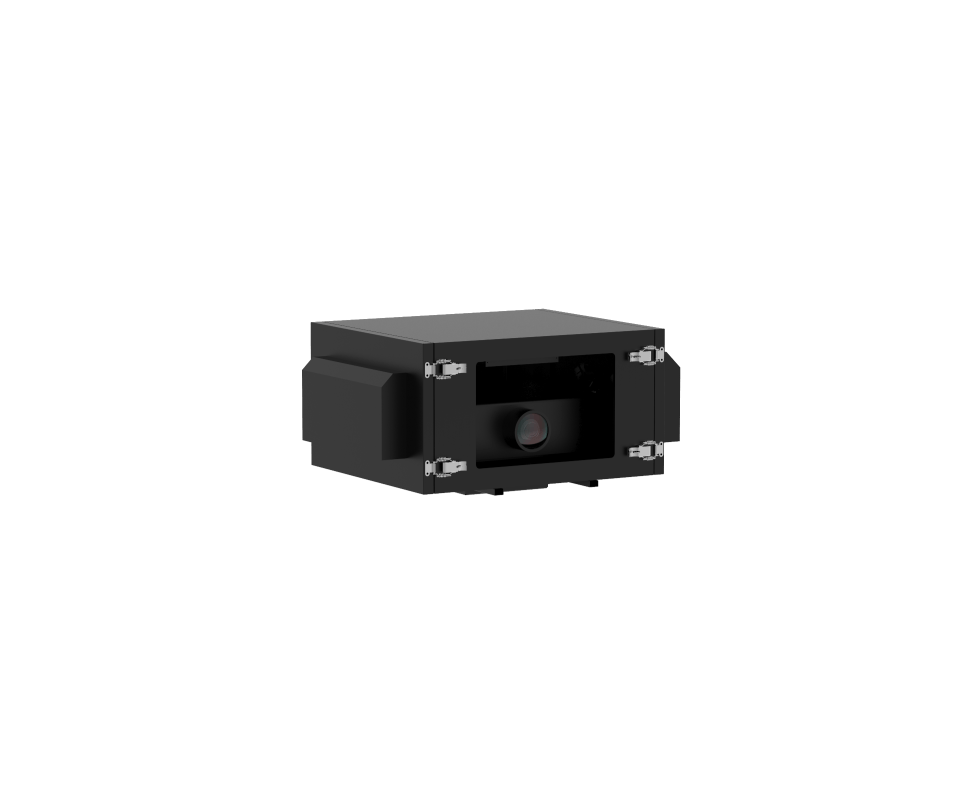

Small Home House Interactive Video Projection Indoor Projector Base Station Waterproof Projector Enclosure Outdoor

The “Small Home House Interactive Video Projection Indoor Projector Base Station Waterproof Projector Enclosure Outdoor” is designed to protect and enable interactive video‑projection setups in both residential and outdoor environments. Whether used as a base station for indoor interactive video mapping or installed outdoors in home gardens, patios or event areas, this enclosure safeguards the projector from moisture, dust, corrosion and public‑use hazards.

Constructed with an outer shell of galvanized steel (or optional stainless steel) sheet metal, the material thickness ranges from approximately 1.2 mm to 4 mm depending on size and configuration. Surface treatment includes putty filling, mechanical sanding, outdoor powder spray‑paint and baking, providing waterproofing, anti‑corrosion, anti‑static and heat‑resistant features. The design incorporates high‑transparency optical glass, a multi‑door layout for easy access, internal air‑cooling or optional air‑conditioning system, and reinforced mounting and hanging rings to ensure stability even in wind‑exposed or publicly used settings. With an IP65 rating, this enclosure is a robust solution that allows interactive projection installations to function reliably across indoor and outdoor spaces.

- Overview

- Recommended Products

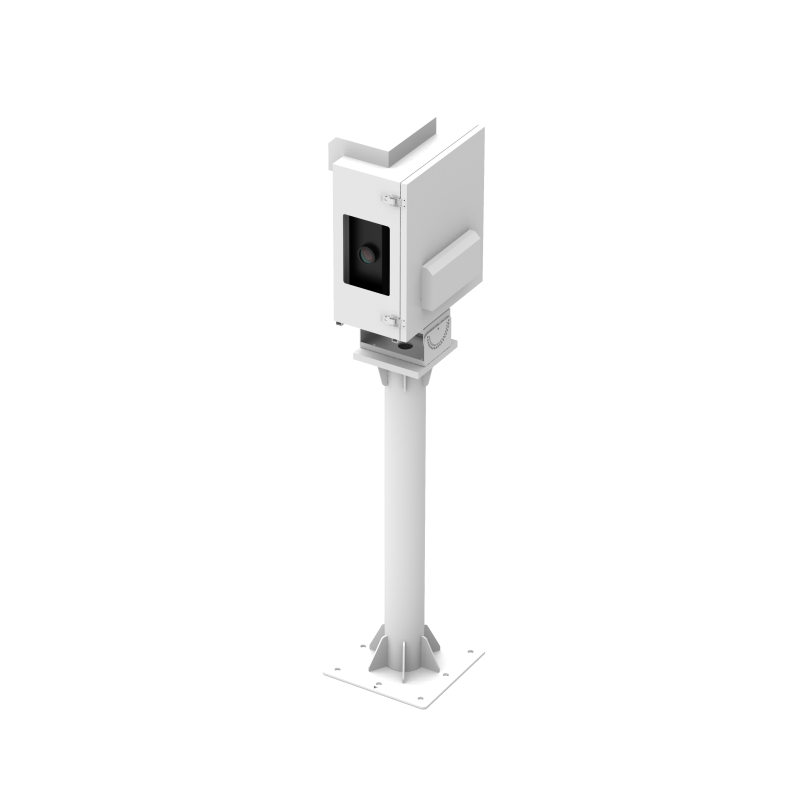

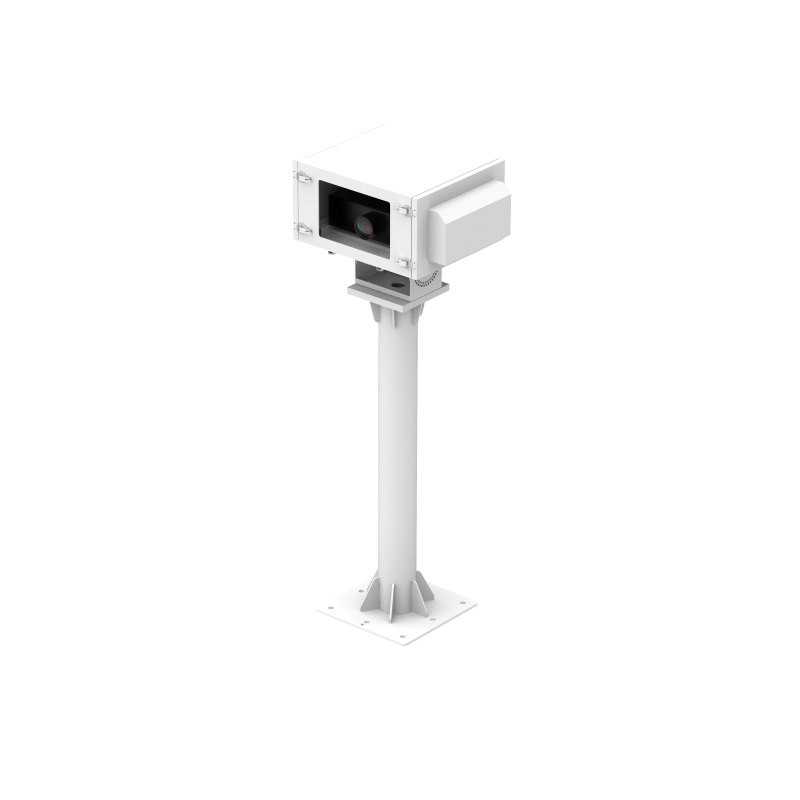

- Utilize industrial silent fans for cooling, expelling hot air from the waterproof box, while simultaneously drawing in fresh air through intake vents to create a circulation effect. This helps reduce the heat emitted by the projector within the waterproof box, and the heating module removes fog and moisture from the glass.

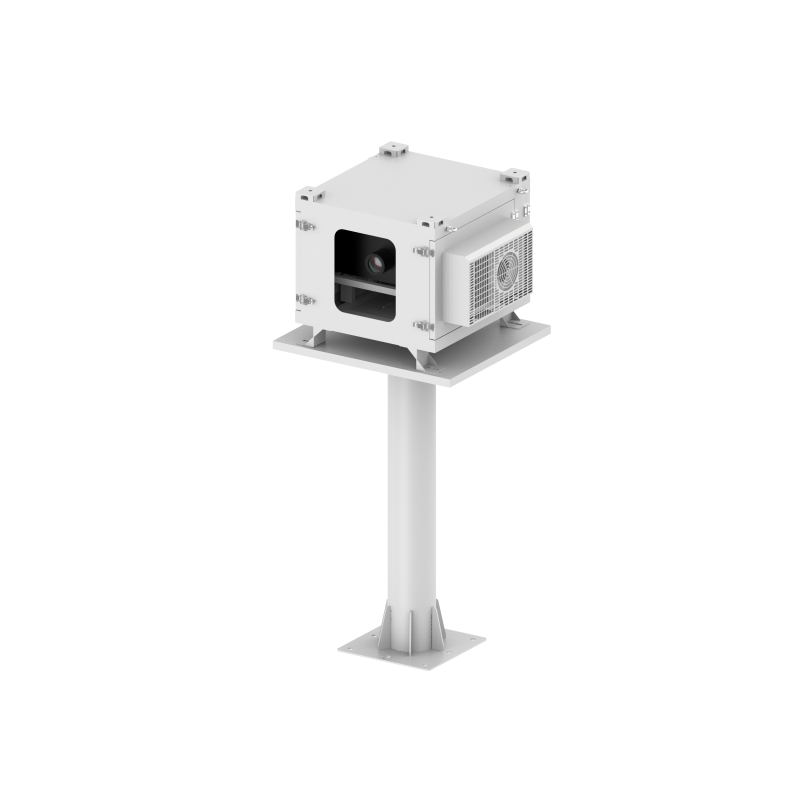

- Fans and air conditioners together form a dual system, used in high lumen machines and also suitable for harsh weather conditions. The air conditioner not only cools but also dehumidifies, while the heating module clears water droplets and fog from the glass.

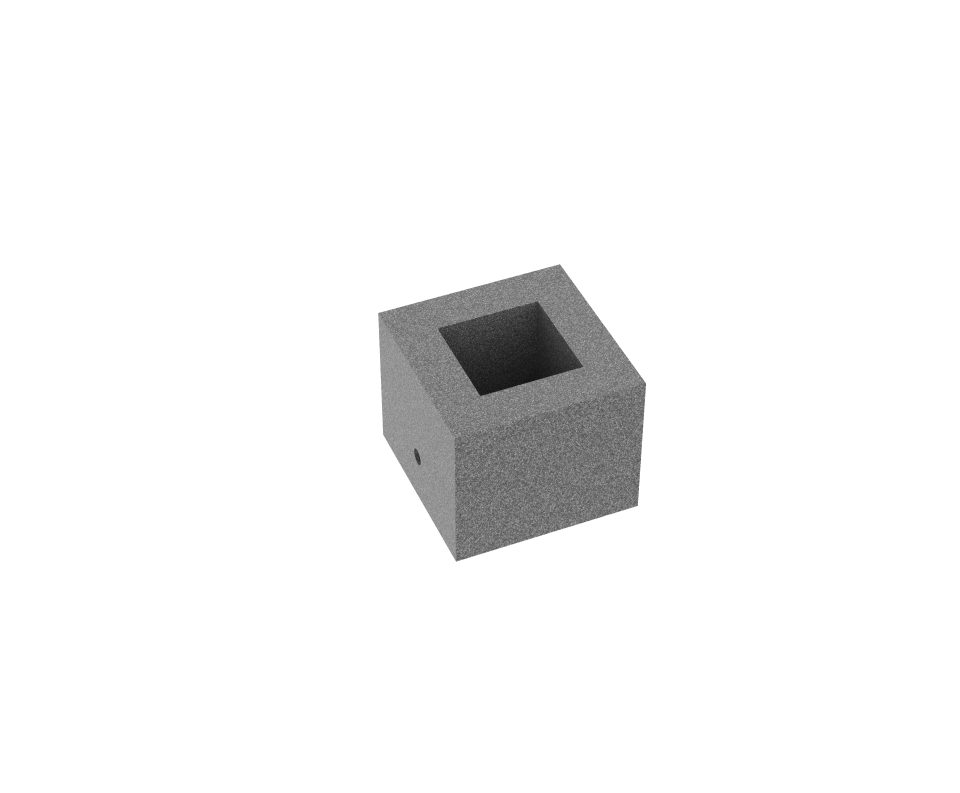

- The material for waterproof boxes is divided into external and internal materials. The external material is typically made from galvanized steel sheets or stainless steel with thicknesses of 1.2-1.5-1.8-4mm, depending on its shape and size. The internal material is usually made from galvanized steel or stainless steel.

- Surface treatment involves applying a secret putty, mechanical sanding, spraying outdoor powder paint, and baking. It offers waterproofing, anti-corrosion, anti-static, and heat resistance features. The color can be customized based on the specific needs of the customer's project.

Product Introduction

Functional Realization

1.The power supply of the smart test and control board is stabilized by the Meanwell switching power supply.

2.Built-in temperature probe and temperature and humidity sensor.

3.3-way adjustable fans, each fan with a peak speed of up to 5000 RPM and an airflow of 5 m³/minute.

4.When the temperature is 2 degrees Celsius higher than the preset temperature (30°C), the fans will start, and the higher the temperature, the faster the fan speed and the greater the airflow.

5.F6 medium efficiency air filter, with high air permeability, dust and mosquito proof functions.

6.Heating module, when the temperature is ≤5°C and the humidity is ≥85%, the heating will start, and when the temperature reaches 10°C and the humidity is ≤75%, the heating will stop.

7.Reserved 16A or 10A multi-function sockets.

8.The power supply for the projector is equipped with an AC contactor. In case of a fault, the power will be immediately cut off to protect the projector.

9.When the internal temperature is 2°C or more above the preset value (30°C), the air conditioning cooling will start, and when it is 2°C or less below the preset value, the cooling will stop.

10.When the internal temperature is 2°C or more above the preset value (35°C), the fan cooling system will start, and when it is 2°C or less below the preset value, the fans will stop.

11.Passed IP65 waterproof certification.

Product Parameters

| External Size | CUSTOM | Material | Galvanized Steel |

| IP level | IP65 | Type | Control Box |

| Model Number | SR-99-TYK | Brand Name | thisshirui |

| Place of Origin | Guangdong, China | Product Name | outdoor projector enclosure |

| Material | Galvanized Steel | Surface treatment | Spray paint |

| Function | Air cooling system thermostat | Application | Outdoor Indoor Electronic Equipment |

| IP Rating | IP65 Waterproof Box | Feature | Safety Durable |

| Service | OEM ODM Customised | Color | Accept Customized |

| Drawing Format | DWG/PDF | ||

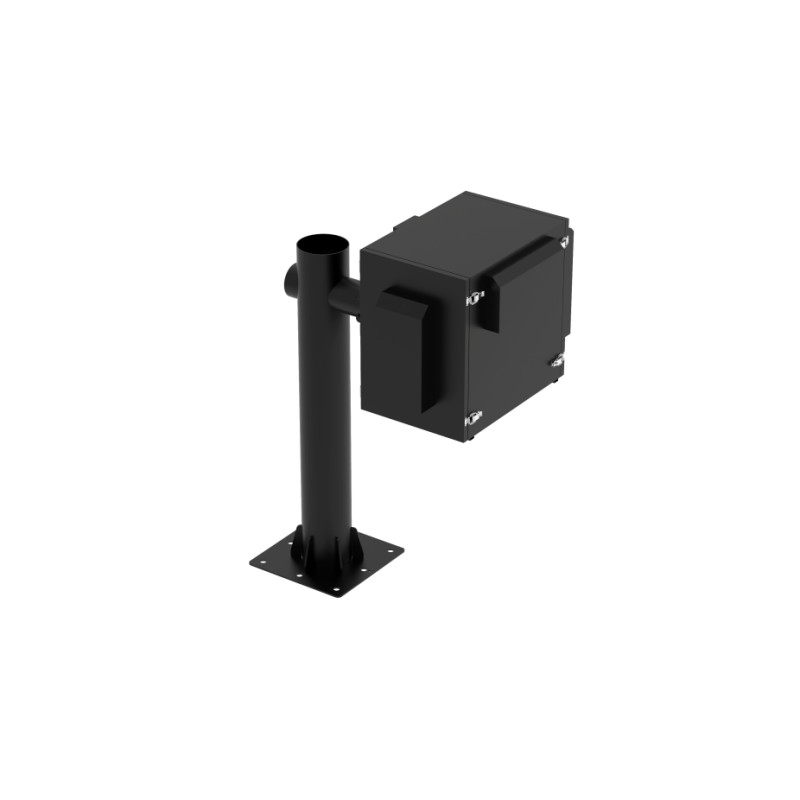

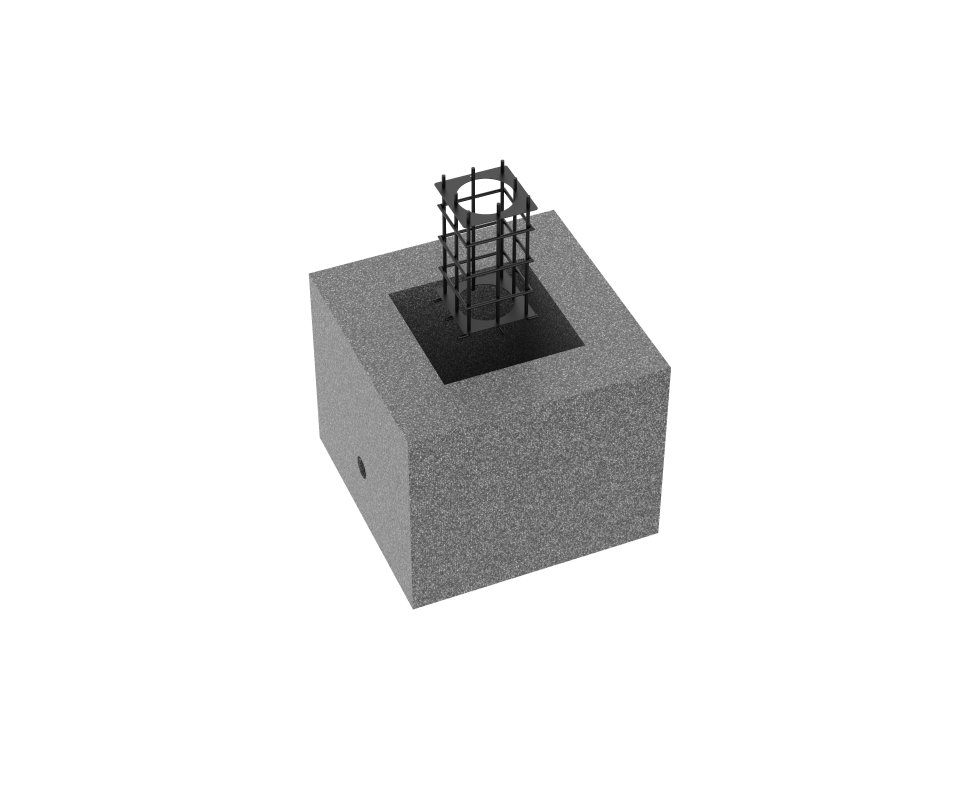

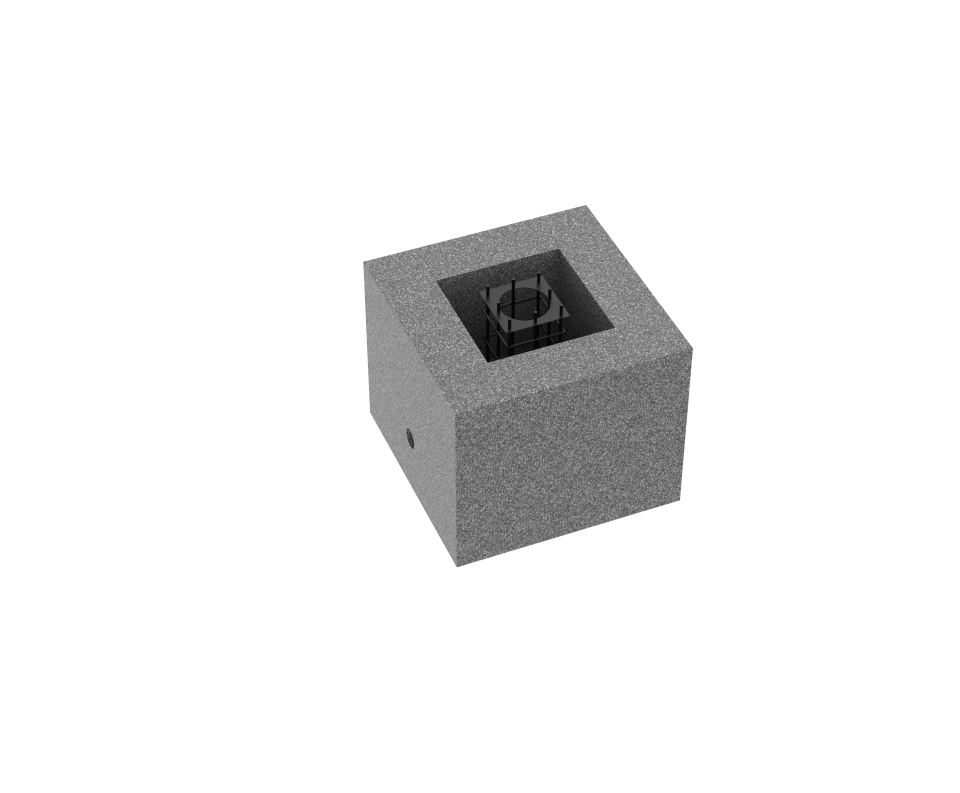

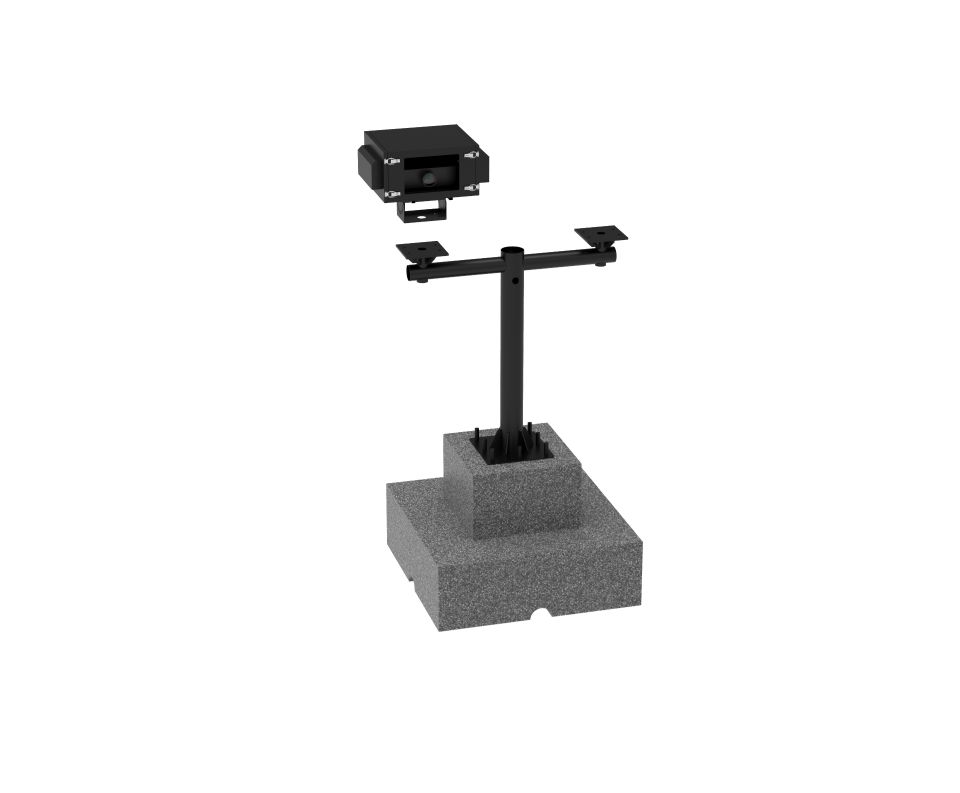

Installation Steps

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

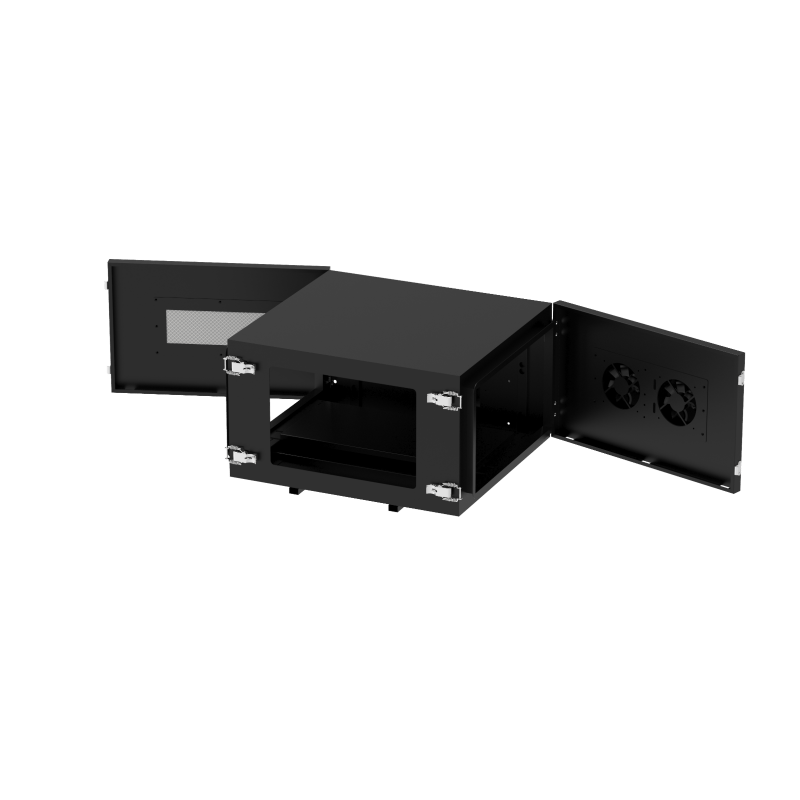

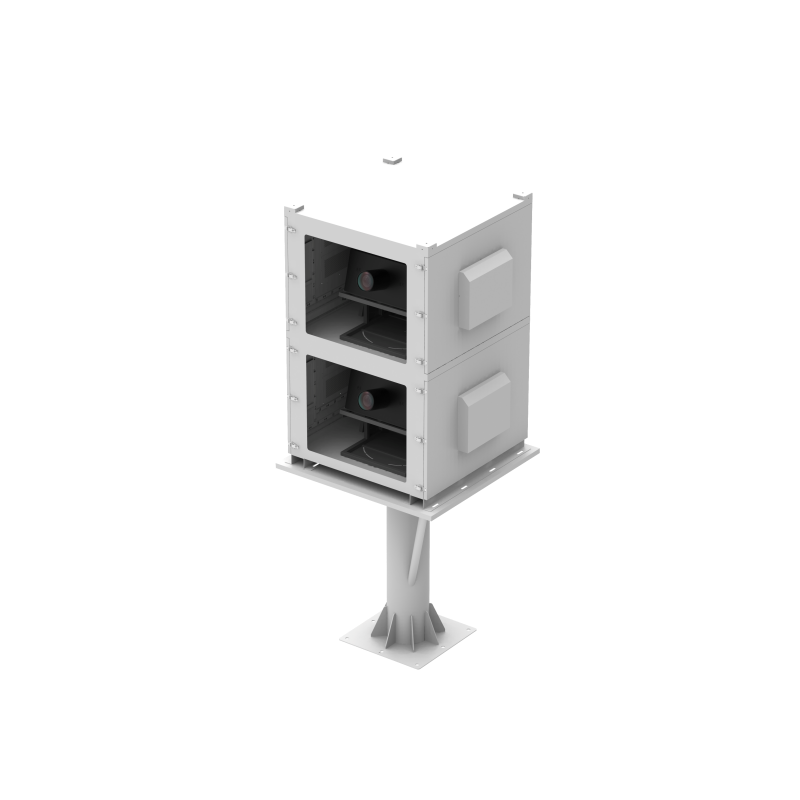

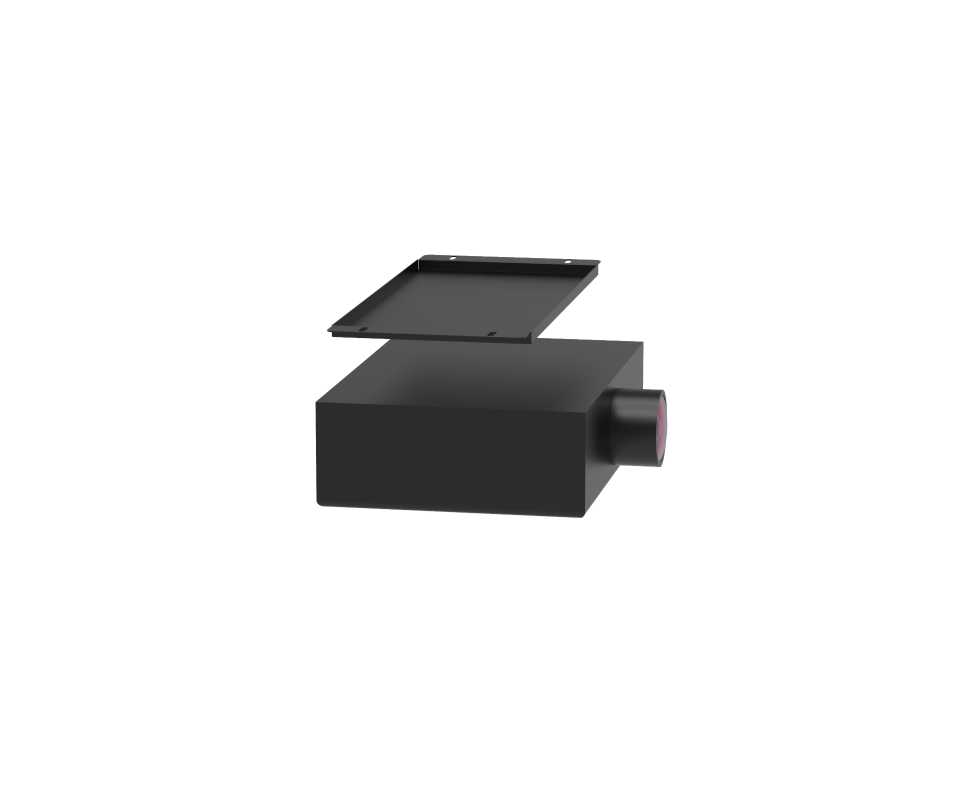

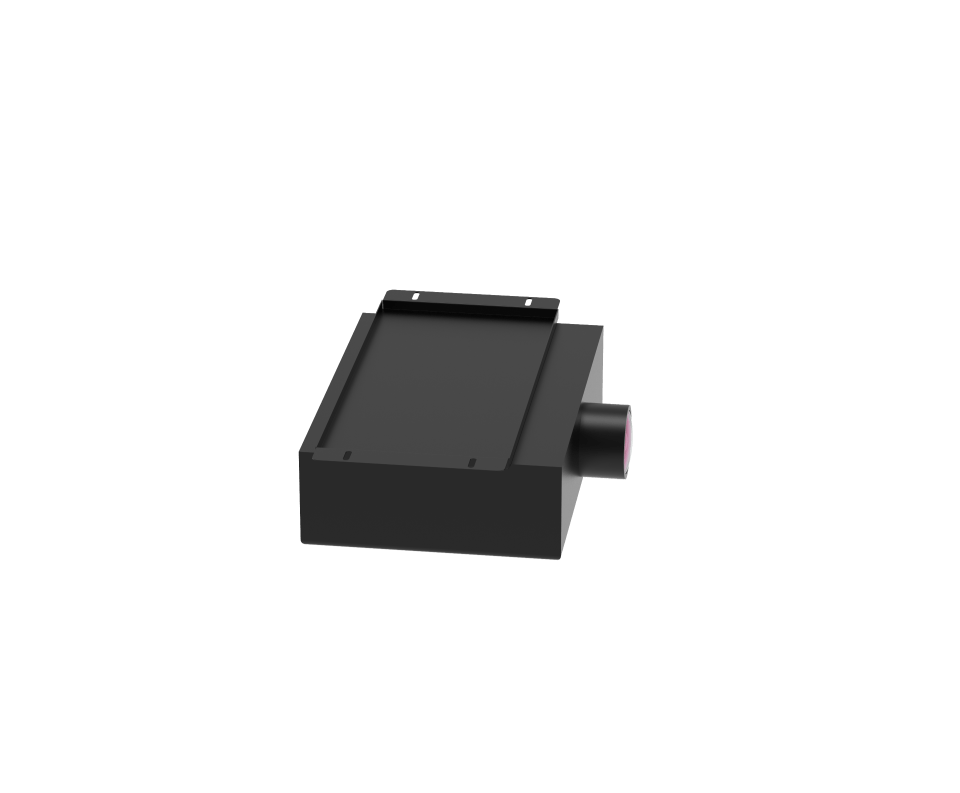

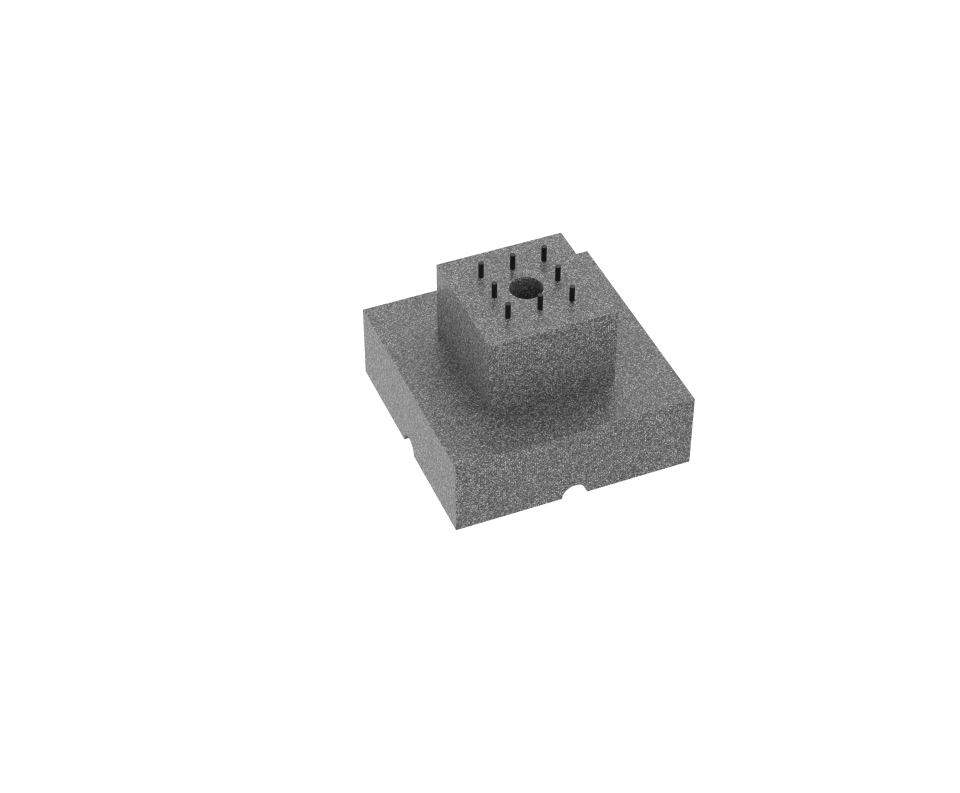

Internal structure of the waterproof box

The waterproof box structure is divided into six main parts: the outer layer of the sheet metal body, the intelligent main control box, the maintenance waterproof door, the projector adjustment base, high-transparency optical glass, and stainless steel installation hanging rings for waterproof box adjustment. The placement method of the projector, the projection method, and the installation method of the waterproof box determine the overall structural design of the waterproof box. In addition to ensuring a stable working environment for the projector, the design of the waterproof box also takes into account the projection angle of the projector and its safety in public places.

Practical features of waterproof boxes

1. The waterproof box has functions such as waterproofing, dustproofing, corrosion resistance, anti-frosting, heating, and dehumidification.

2. The projector platform allows for linear angle adjustment (up to 10 degrees, with larger adjustment angles available upon customization).

3. The multi-door design facilitates easy installation and maintenance of the projector.

4. It is equipped with an internal hot air blower to ensure that there is no frost or fog on the projection surface.

5. The tripod and door use reinforced structures designed for strong wind solidification, and additional hanging protection ensures the safety of the waterproof box before and after installation.

6. Inside, it includes a 32A AC contactor, a 16A or 10A multifunctional socket.

7. The projection port uses optical ultra-white glass with a 95% light transmission rate.

Wind-cooling

Air-conditioning

Waterproof box material

Surface treatment