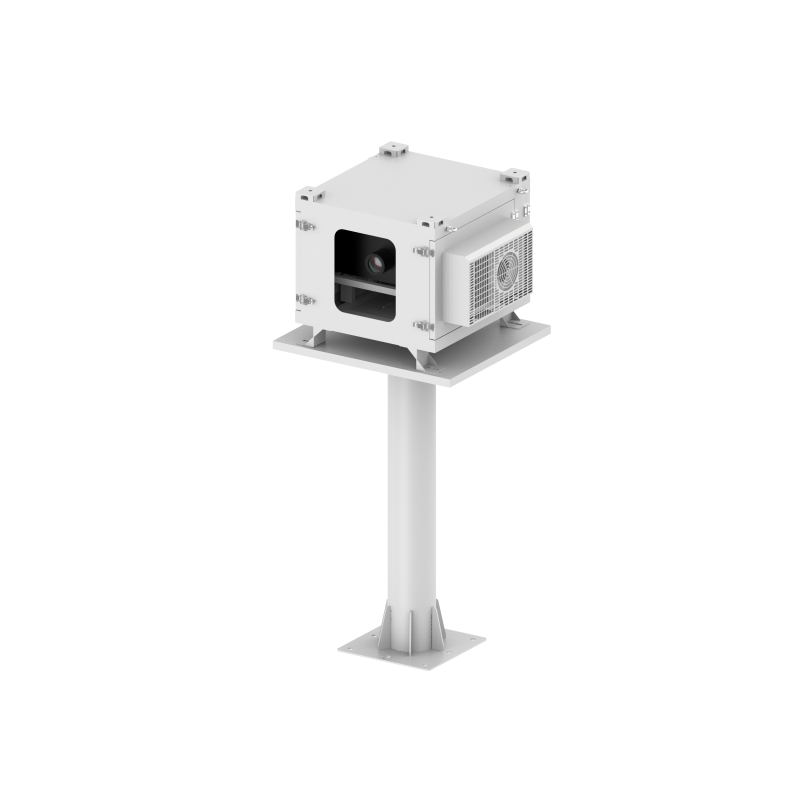

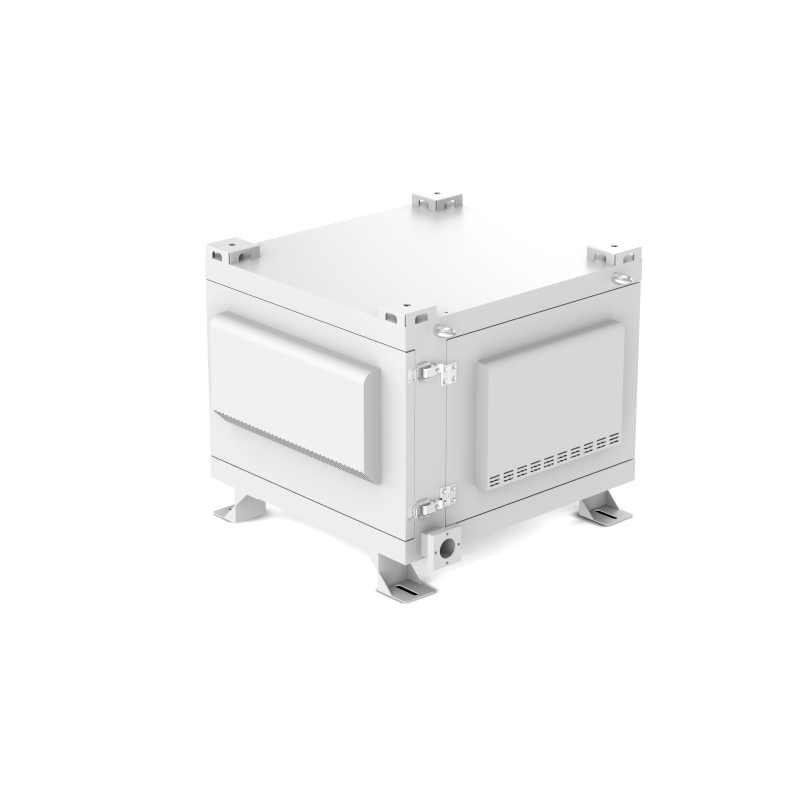

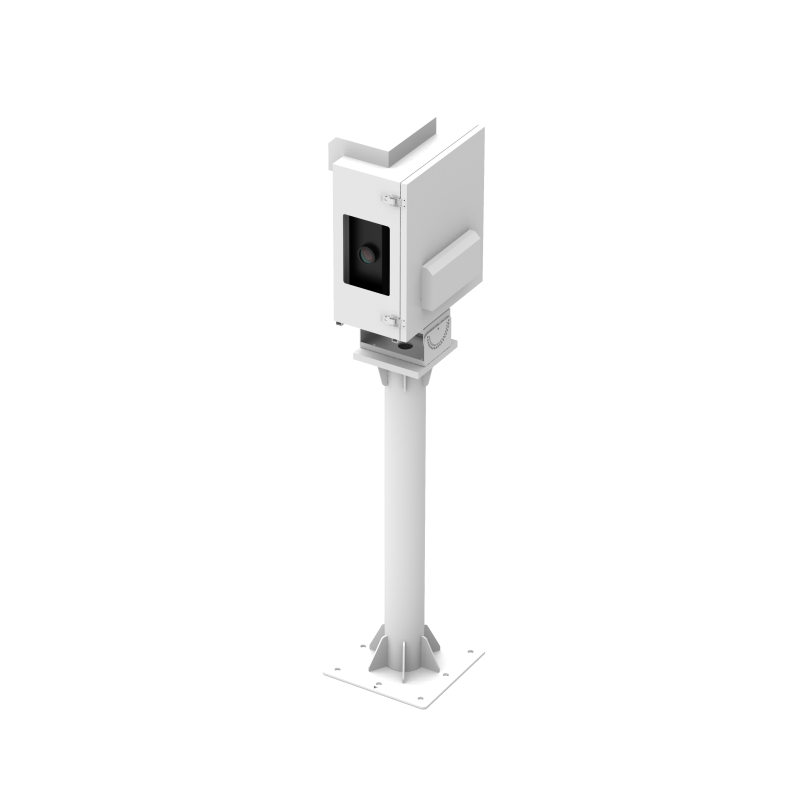

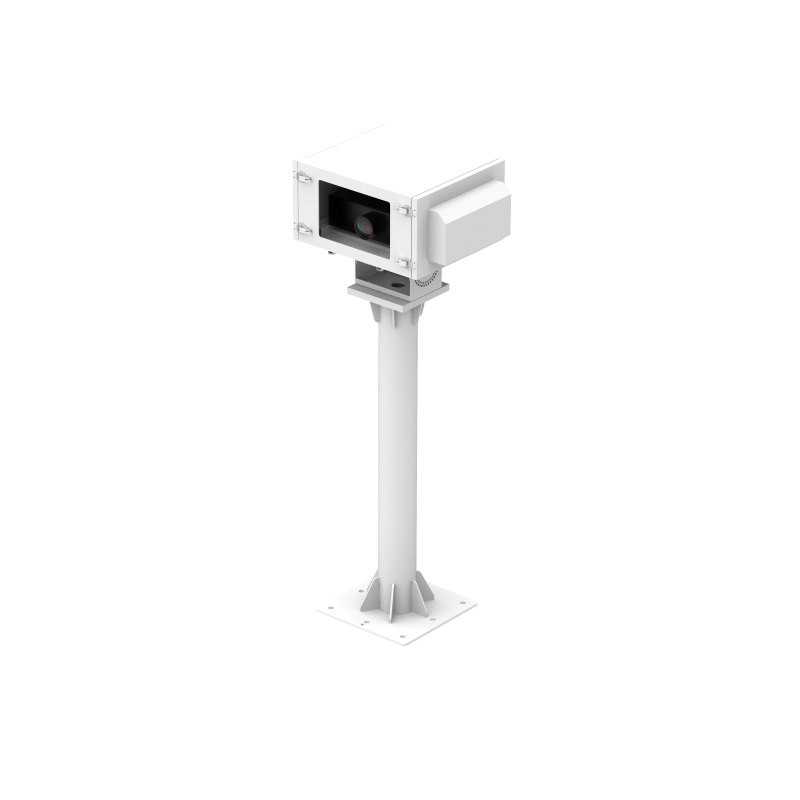

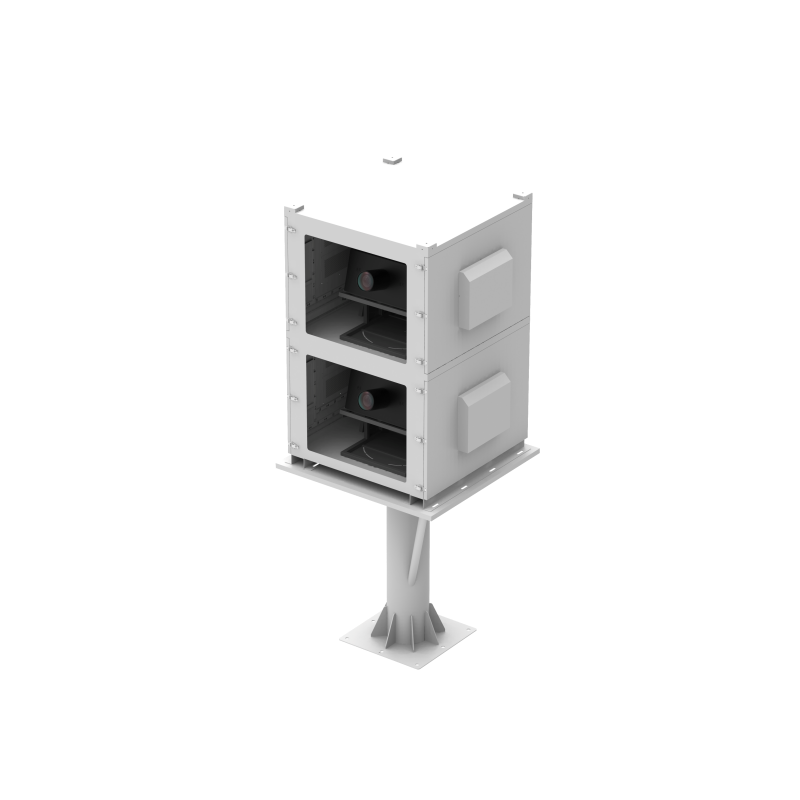

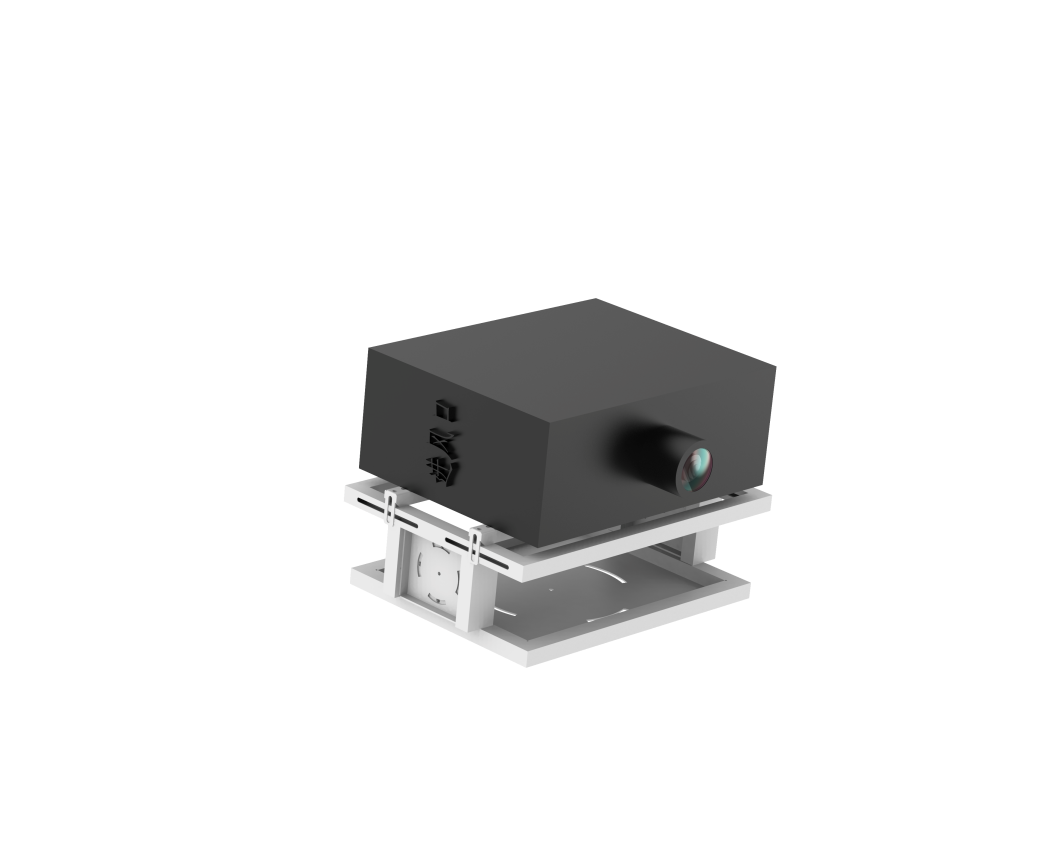

Outdoor Projector Enclosure for All Environments Outdoor Enclosure for Projector

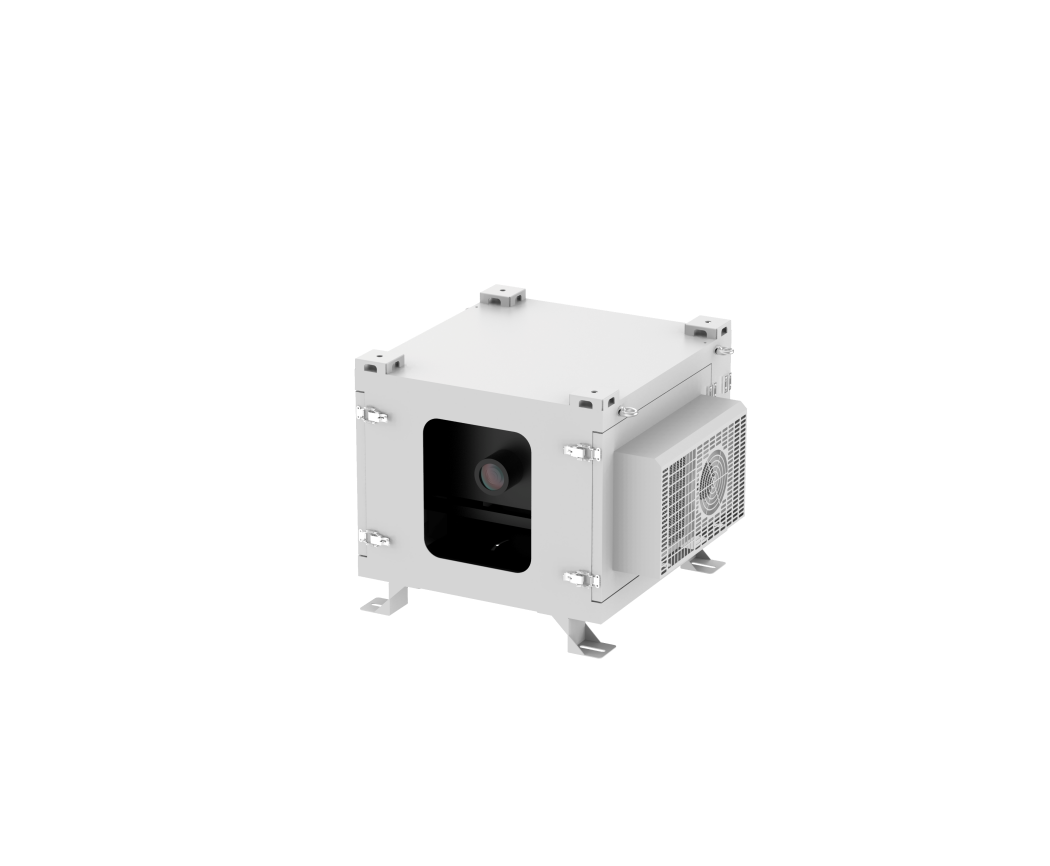

The Outdoor Projector Enclosure for All Environments / Outdoor Enclosure for Projector is designed to enable projection systems to operate reliably in demanding outdoor conditions. It is widely used for outdoor cinemas, architectural projection mapping, theme-park attractions, sports venues, advertising displays, and public signage installations where exposure to weather, dust, and temperature fluctuations may damage equipment.

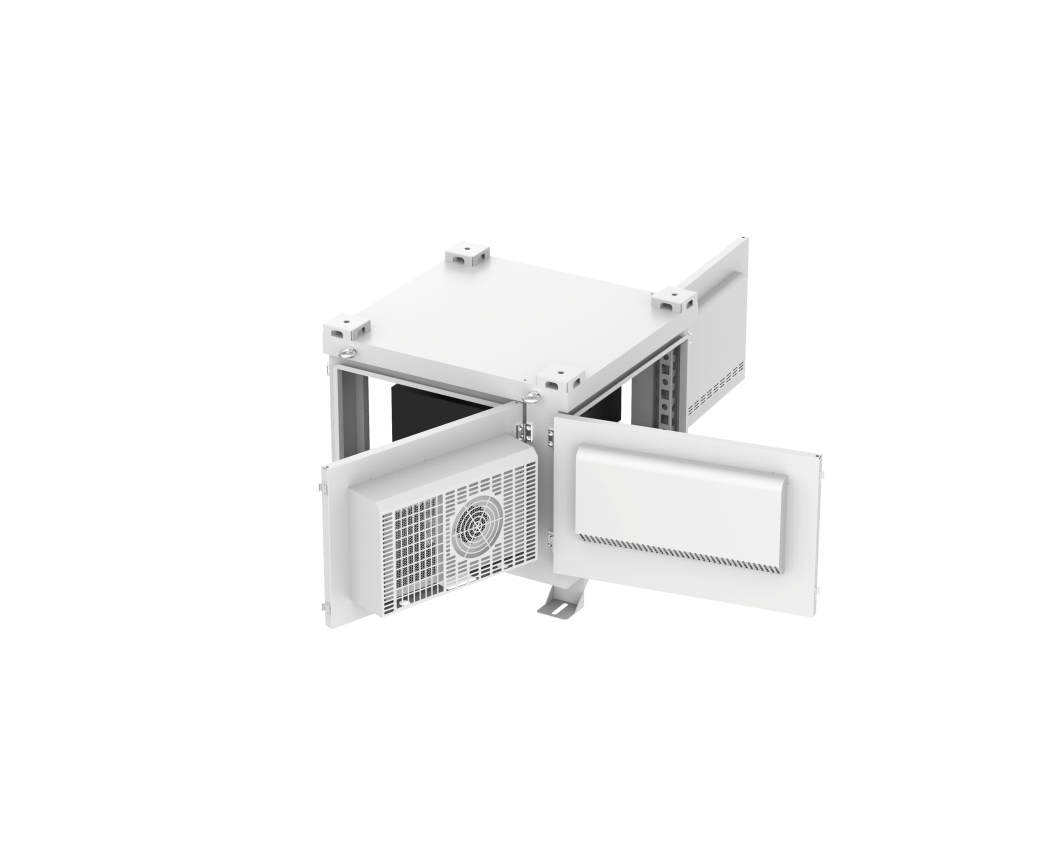

This enclosure provides a sealed, weather-resistant environment to protect the projector from rain, moisture, dust, and wind. It helps maintain stable image performance and reduces maintenance frequency, allowing long-term outdoor operation. The design can also accommodate temperature-control components such as fans, hot-air blowers, or optional air-conditioning modules to ensure proper thermal management in both hot and cold climates.

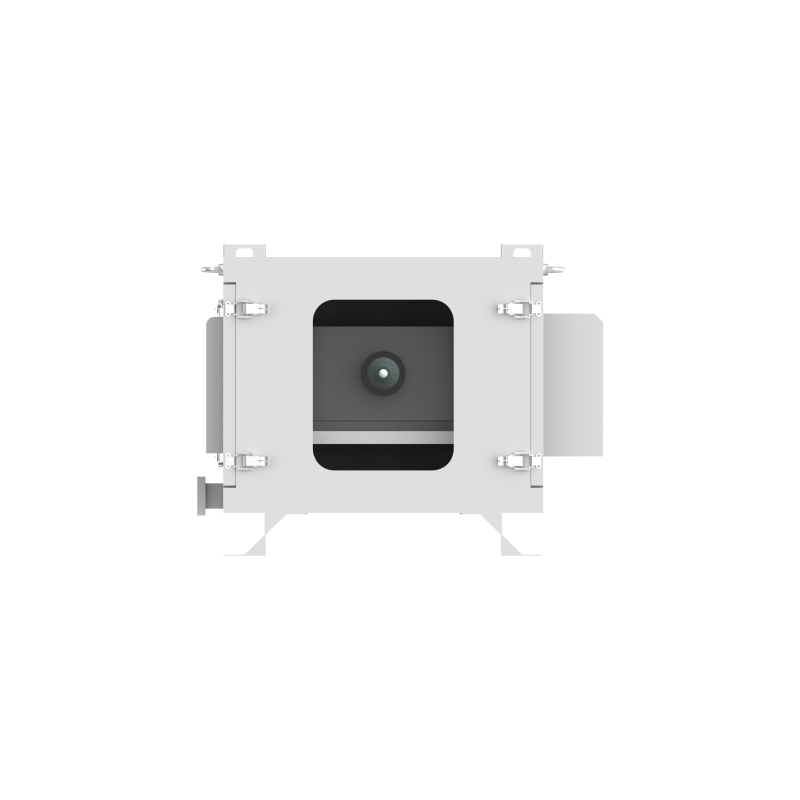

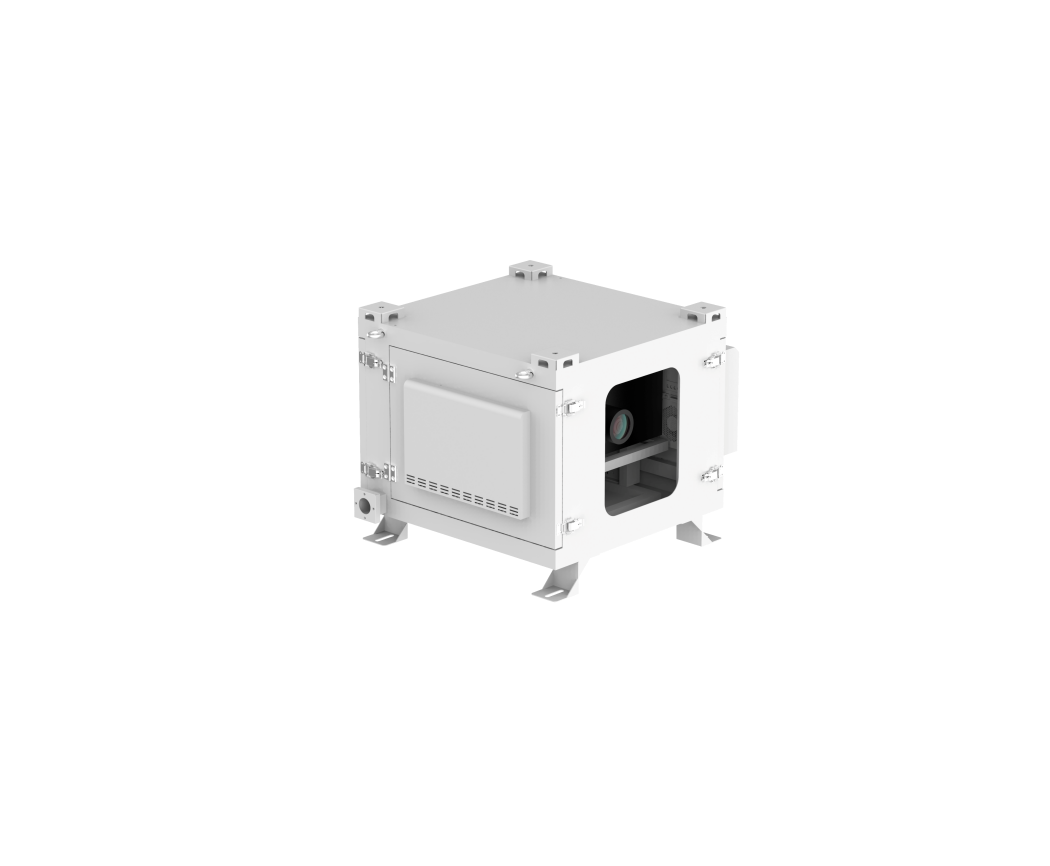

In terms of materials, the enclosure is constructed from durable galvanized steel or optional stainless-steel sheets, typically ranging from 1.2 mm to 4 mm in thickness depending on size and structural requirements. The surface undergoes mechanical sanding, putty filling, powder-coat spraying, and baking to provide corrosion resistance, anti-static properties, and enhanced durability. A high-transparency optical glass window with approximately 95% light transmittance ensures image clarity while shielding the projector lens. Together, these materials deliver a strong and reliable protection solution for outdoor projection applications.

- Overview

- Recommended Products

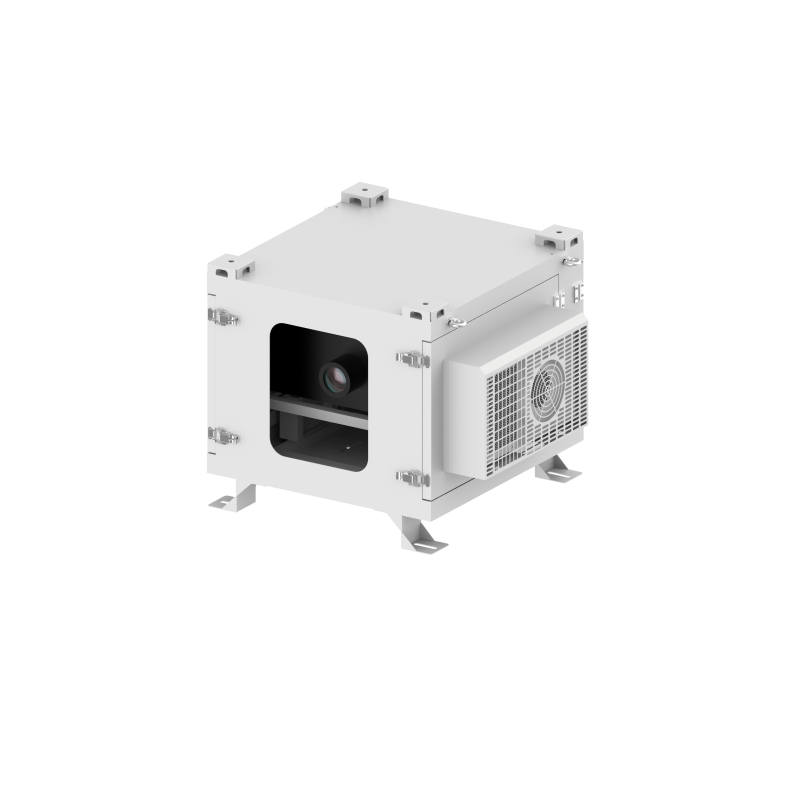

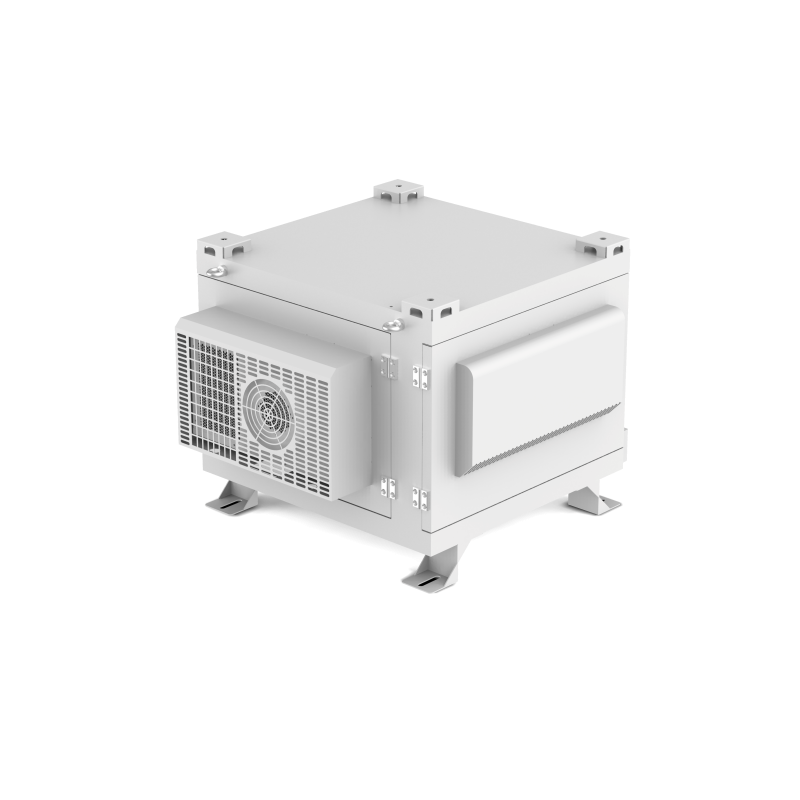

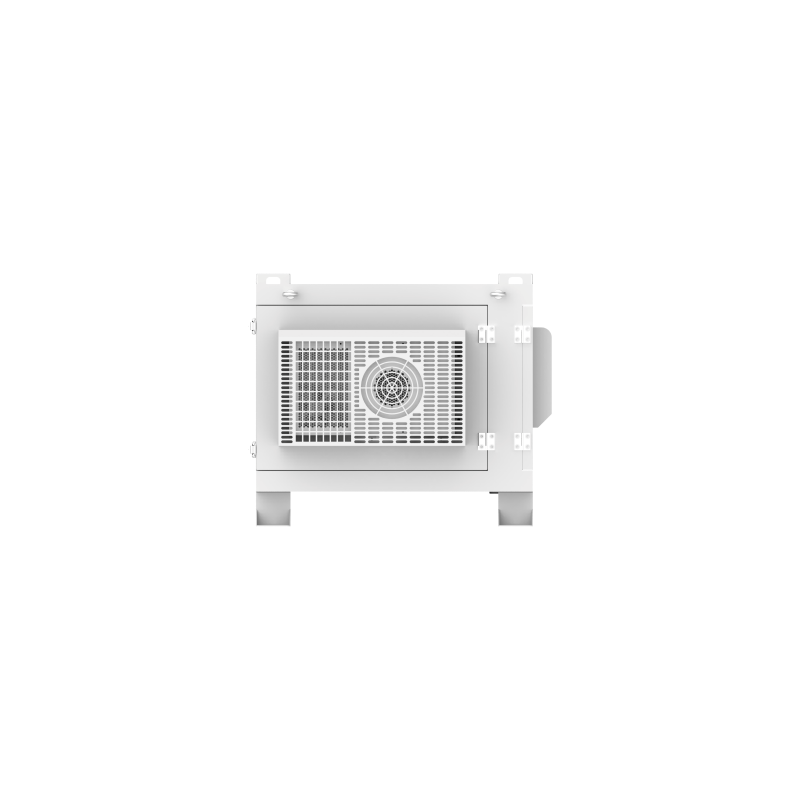

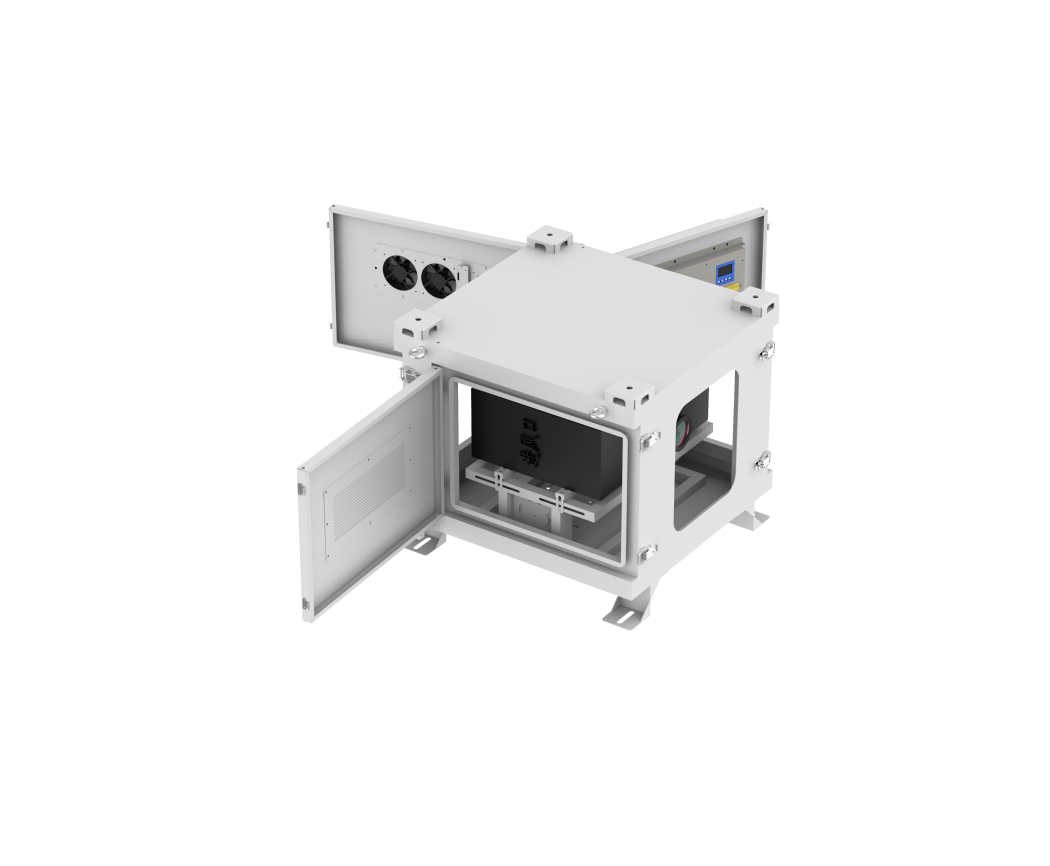

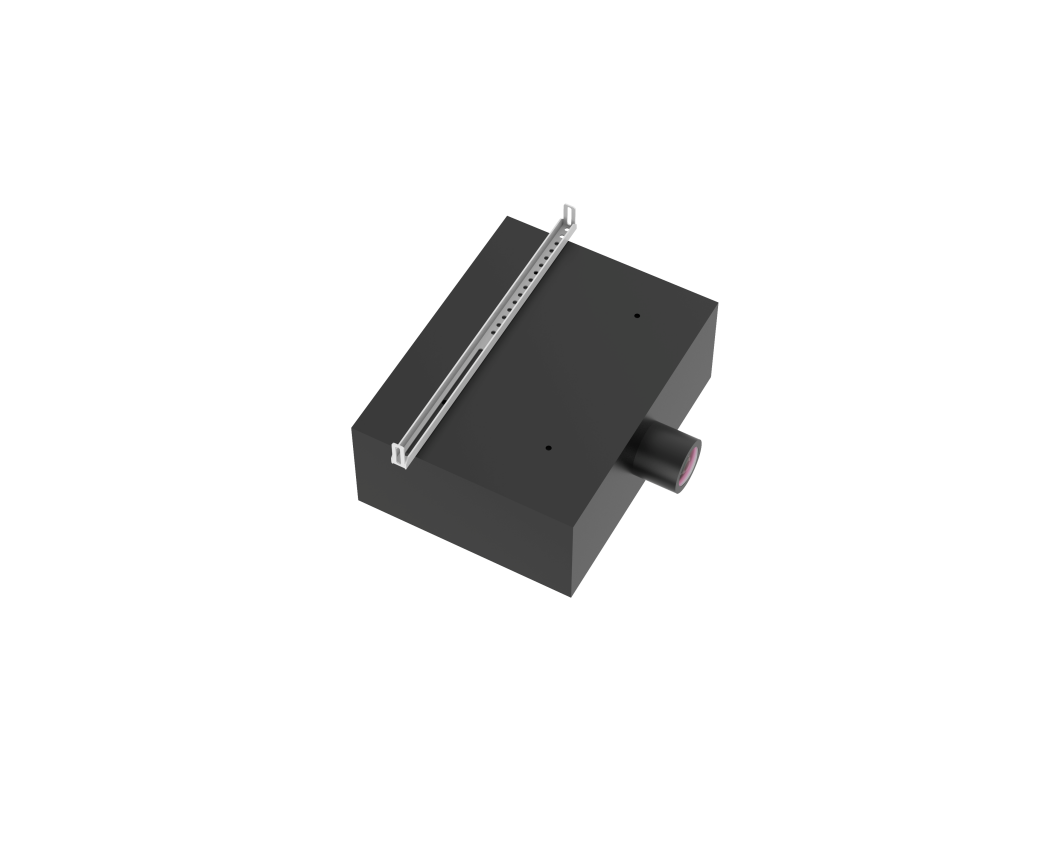

- Utilize industrial silent fans for cooling, expelling hot air from the waterproof box, while simultaneously drawing in fresh air through intake vents to create a circulation effect. This helps reduce the heat emitted by the projector within the waterproof box, and the heating module removes fog and moisture from the glass.

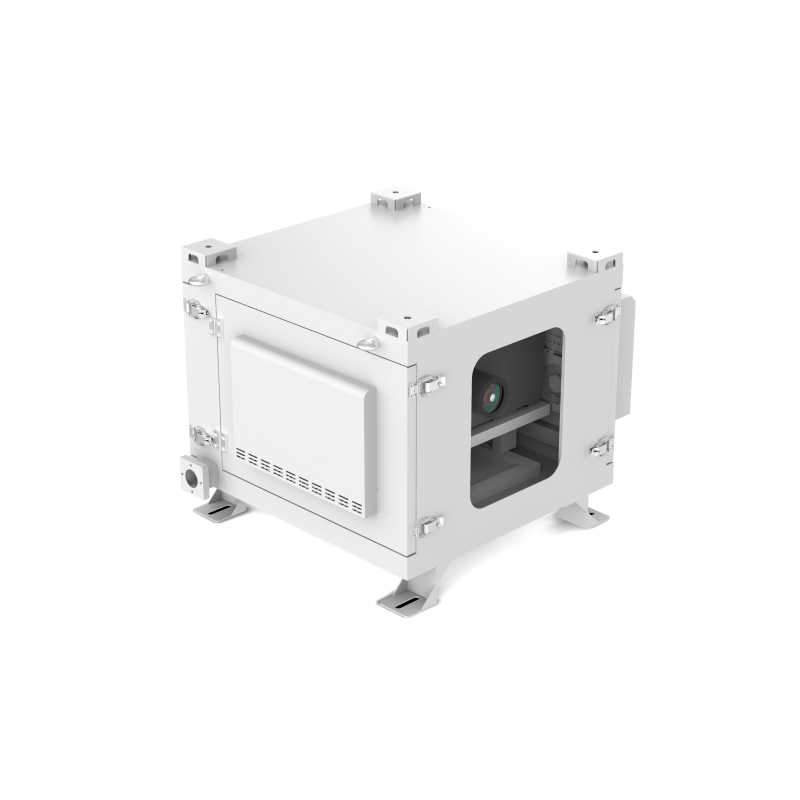

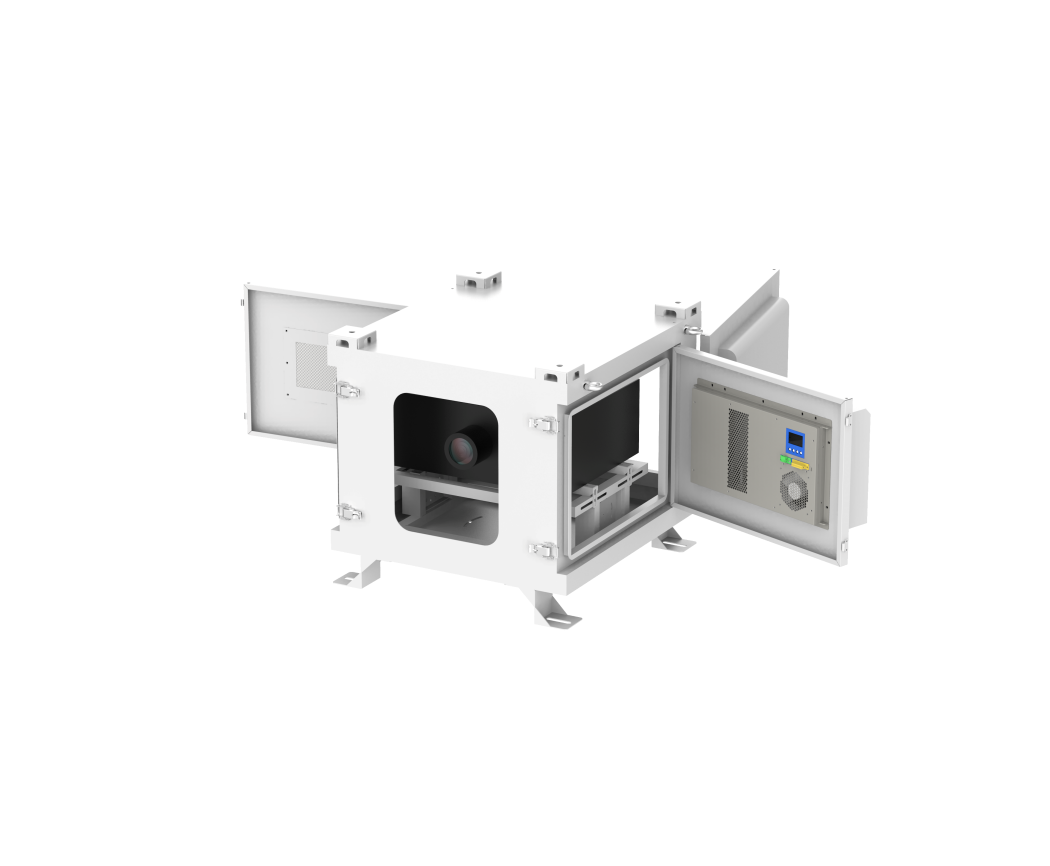

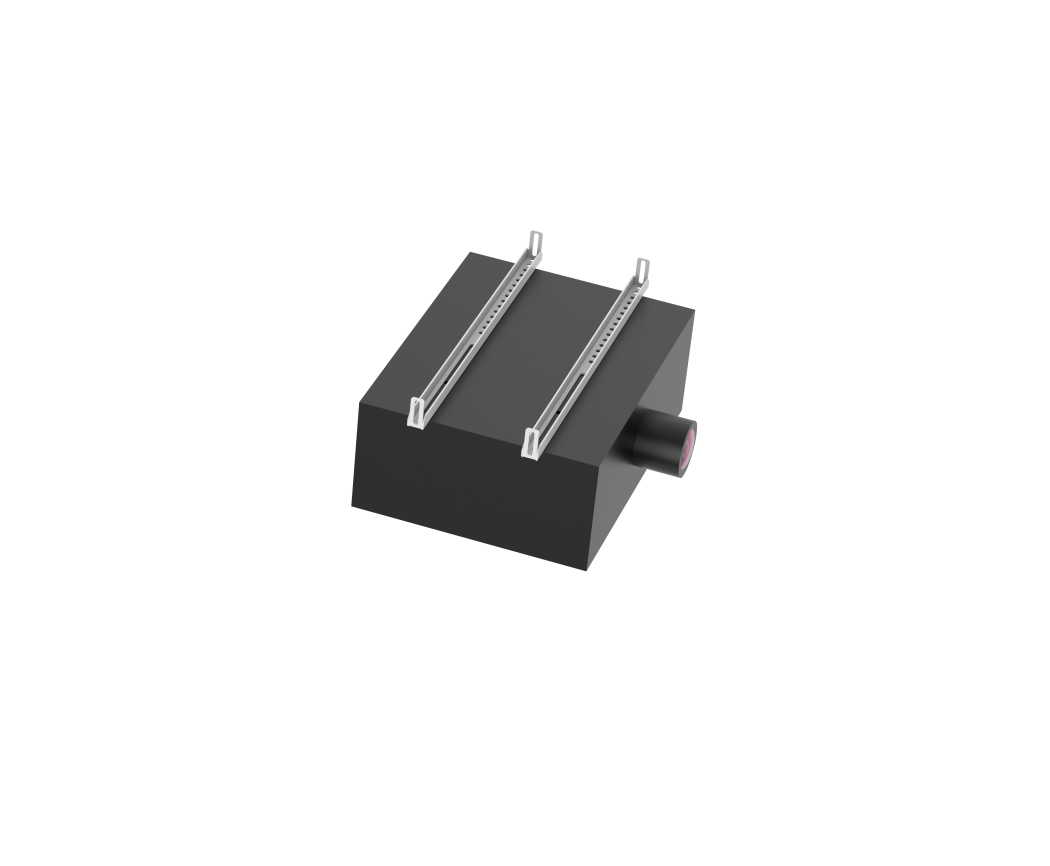

- Fans and air conditioners together form a dual system, used in high lumen machines and also suitable for harsh weather conditions. The air conditioner not only cools but also dehumidifies, while the heating module clears water droplets and fog from the glass.

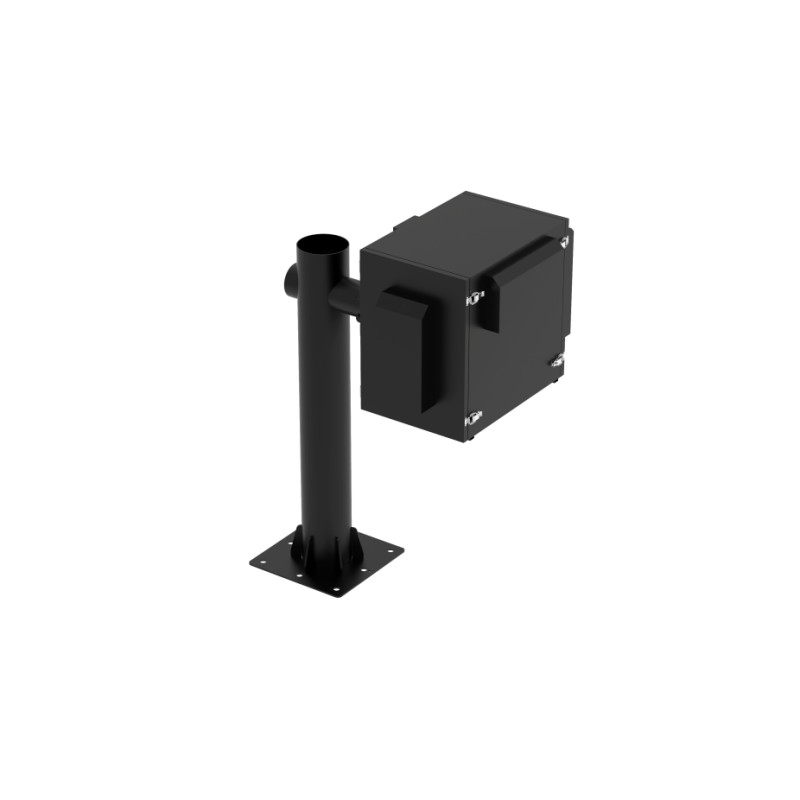

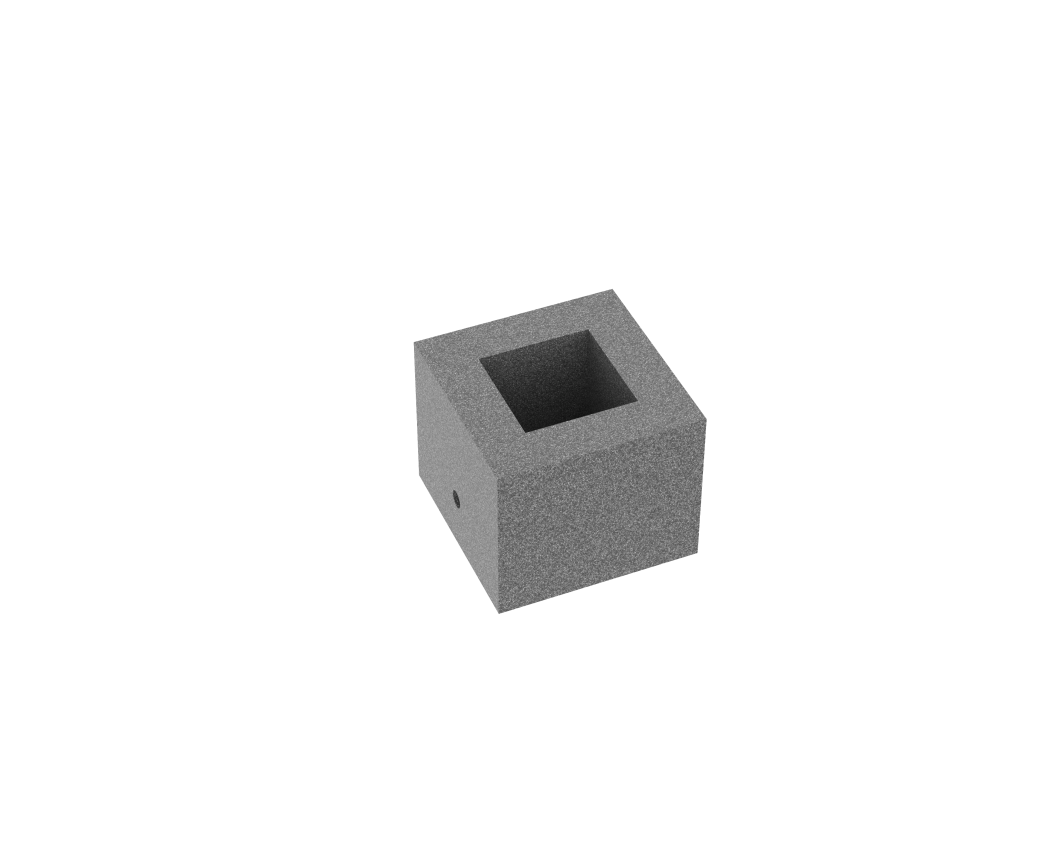

- The material for waterproof boxes is divided into external and internal materials. The external material is typically made from galvanized steel sheets or stainless steel with thicknesses of 1.2-1.5-1.8-4mm, depending on its shape and size. The internal material is usually made from galvanized steel or stainless steel.

- Surface treatment involves applying a secret putty, mechanical sanding, spraying outdoor powder paint, and baking. It offers waterproofing, anti-corrosion, anti-static, and heat resistance features. The color can be customized based on the specific needs of the customer's project.

Product Introduction

Features of internal circulation projector housing:

1.Dust-proof sealing design

The protective box is designed with good sealing performance, which can prevent dust, particles, etc. from entering the interior and protect the projector from contamination. Use sealing strips or gaskets at the joints of the box to form a good sealing barrier.

2.Waterproof performance

The protective box adopts a waterproof and moisture-proof design, with an IP66 waterproof rating, which can resist external rain, water spray, etc. The box material and connections adopt waterproof technology to ensure that the internal projector is protected from water vaporor liquid.

3.Temperature adjustment

The protective box has a built-in temperature adjustment system, including air conditioners, fans, heating sheets, etc., which can automatically adjust ventilation and heat dissipation according to the internal temperature. Ensure that the projector can maintain optimal working conditions even in high temperature environments.

4.Anti-impact design

The protective box is made of strong and durable shell material, which can resist a certain degree of external impact and extrusion. It is also equipped with a shock-absorbing device inside to further protect the projector from vibration and shock.

Product Parameters

| External Size | Custom | Material | Galvanized steel |

| IP level | IP65 | Type | Control Box |

| Model Number | SR-12K-GDJKD | Brand Name | thisshirui |

| Place of Origin | Guangdong,China | Product Name | Outdoor projector enclosure |

| Material | Galvanized steel | Surface Treatment | Spray paint |

| Function | Waterproof dustproof control box | Drawing Format | DWG/PDF |

| IP Rating | IP65 Waterproof Box | Application | Protect appliance |

| Applicable Scene | Projection show | Customization | Accept enclosure customized |

| Performance | Automatic temperature and humidity control | ||

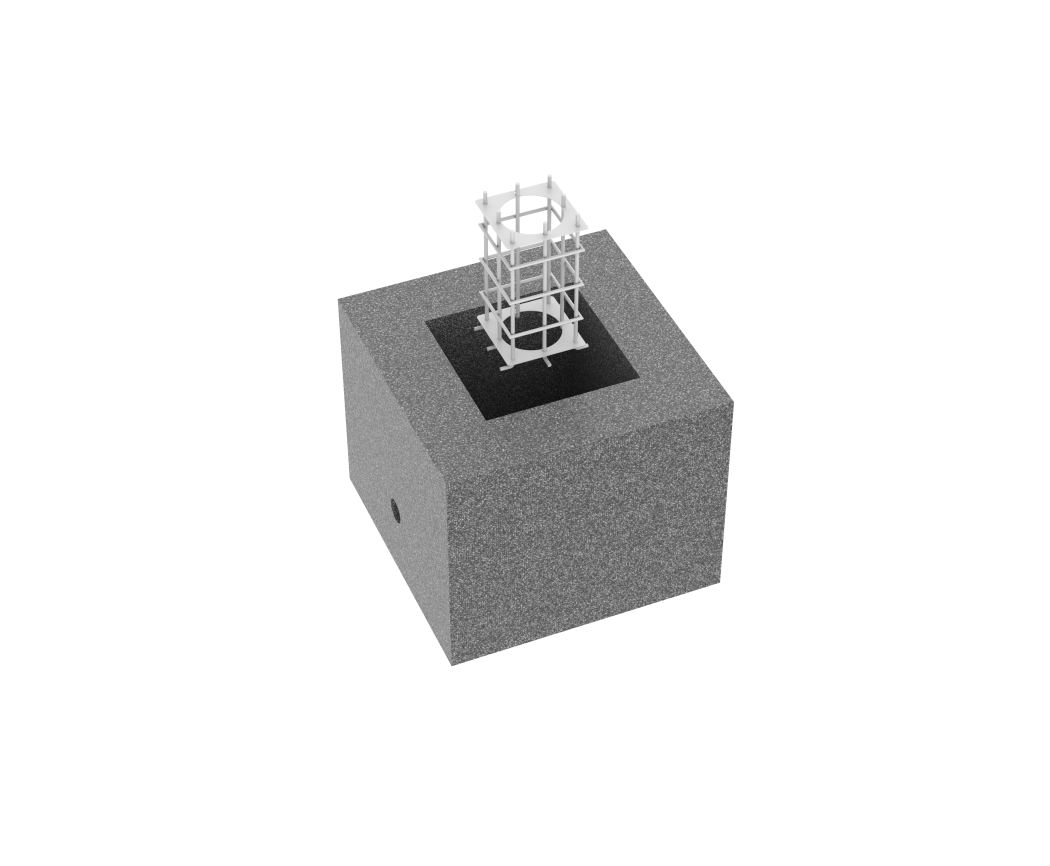

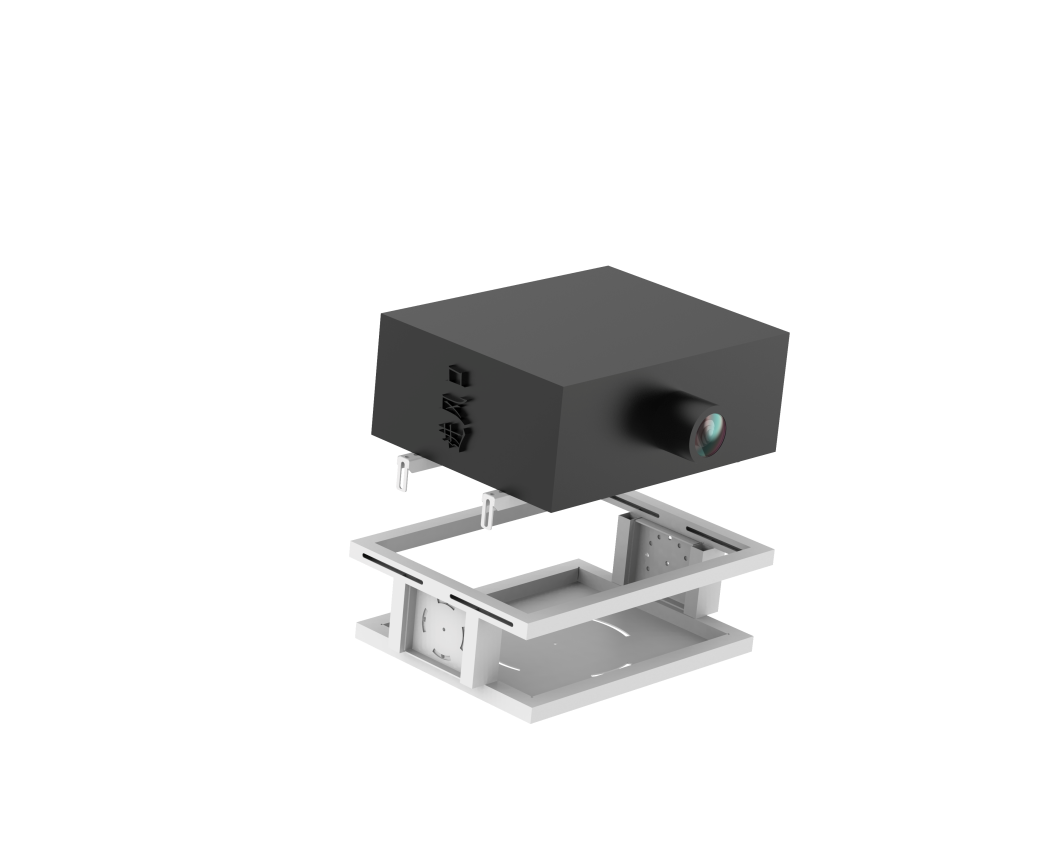

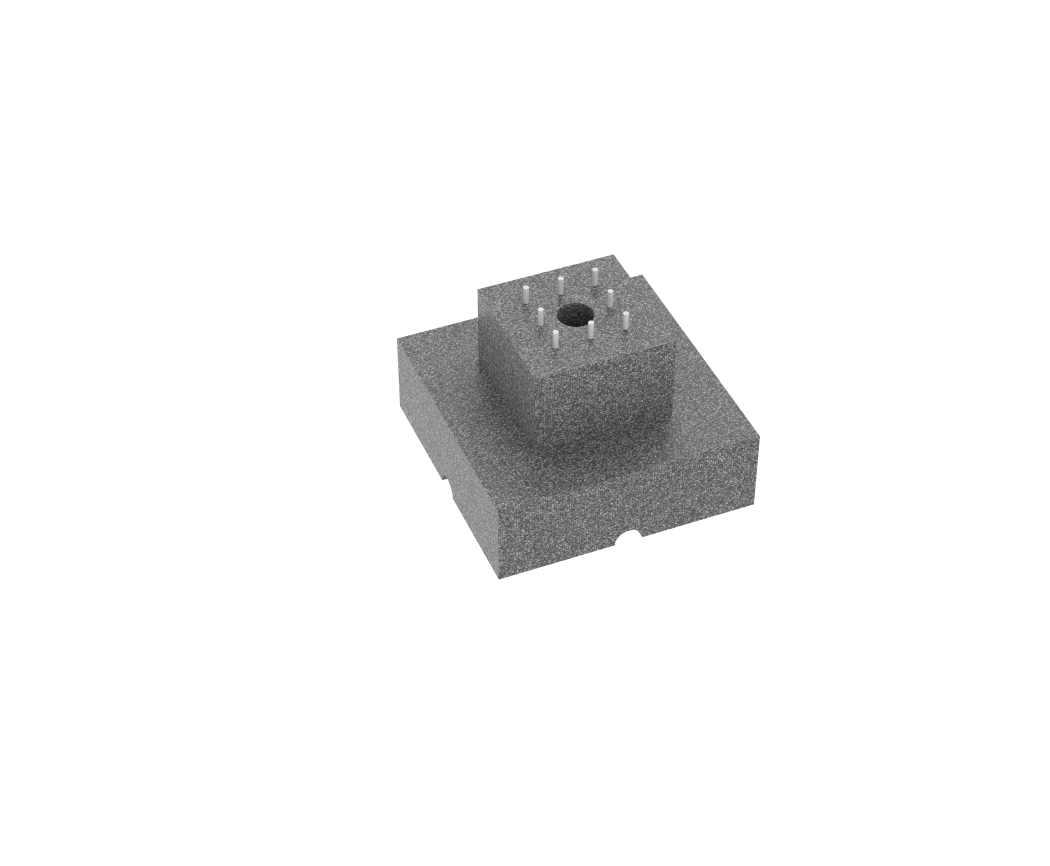

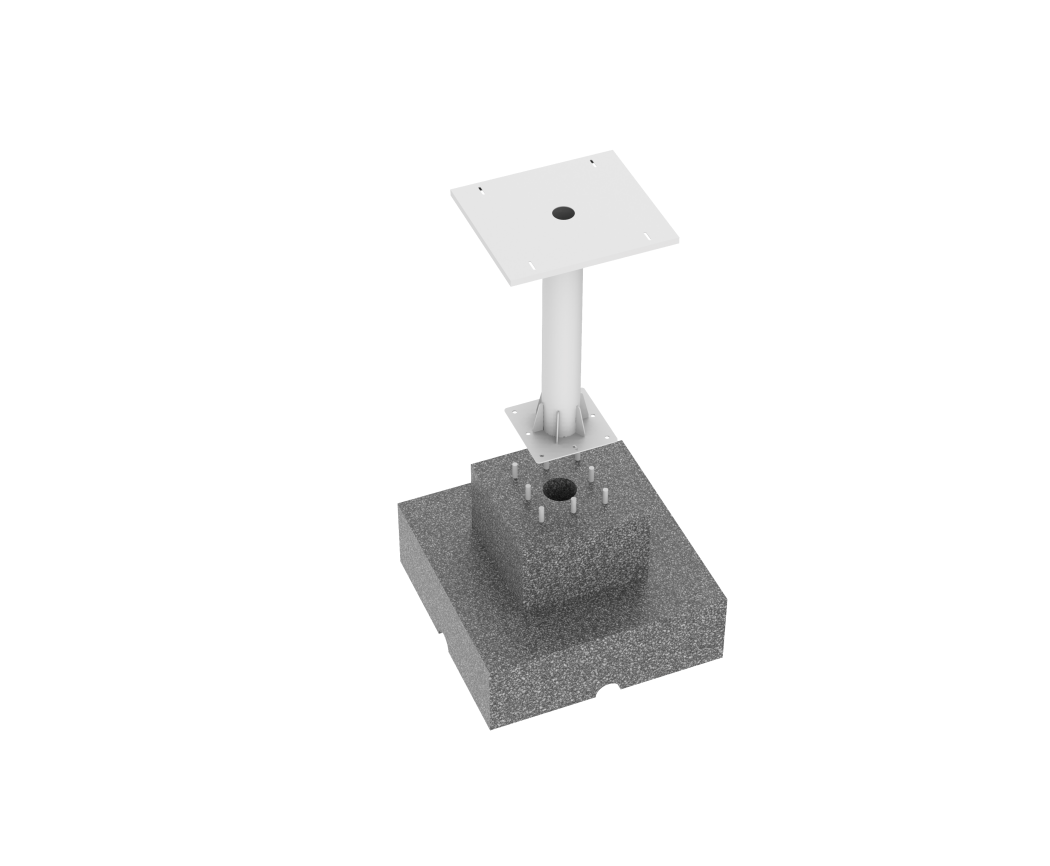

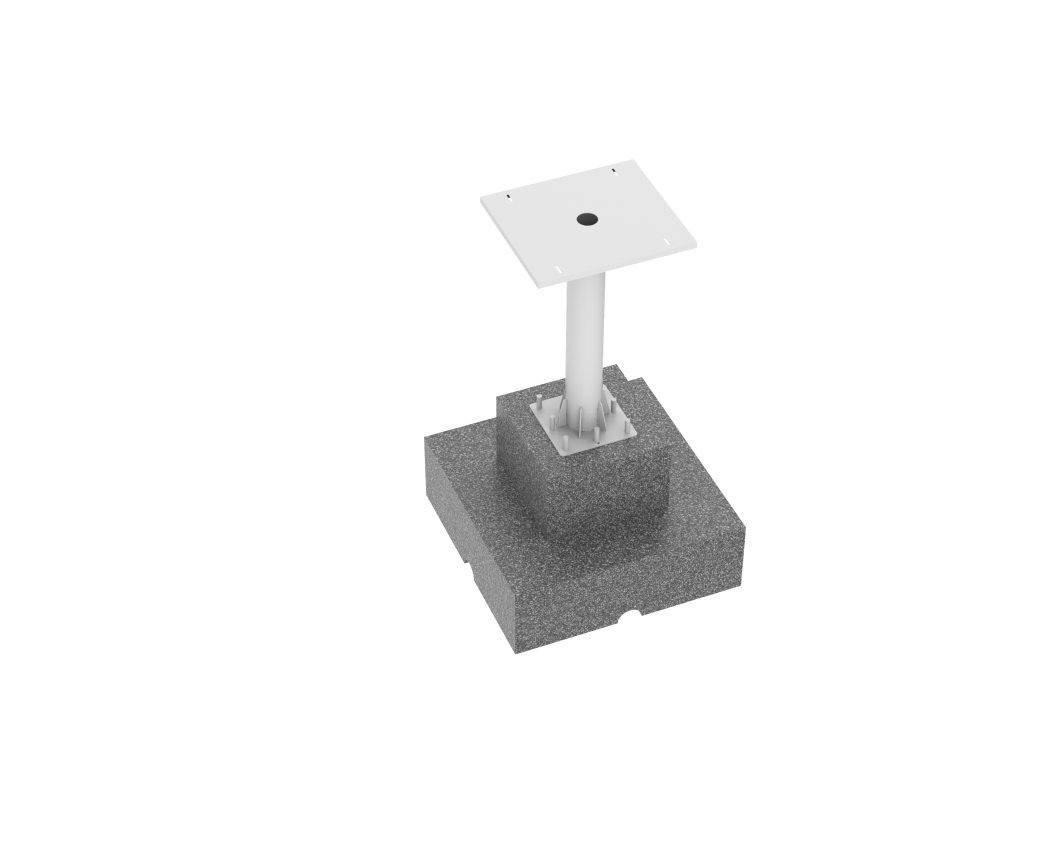

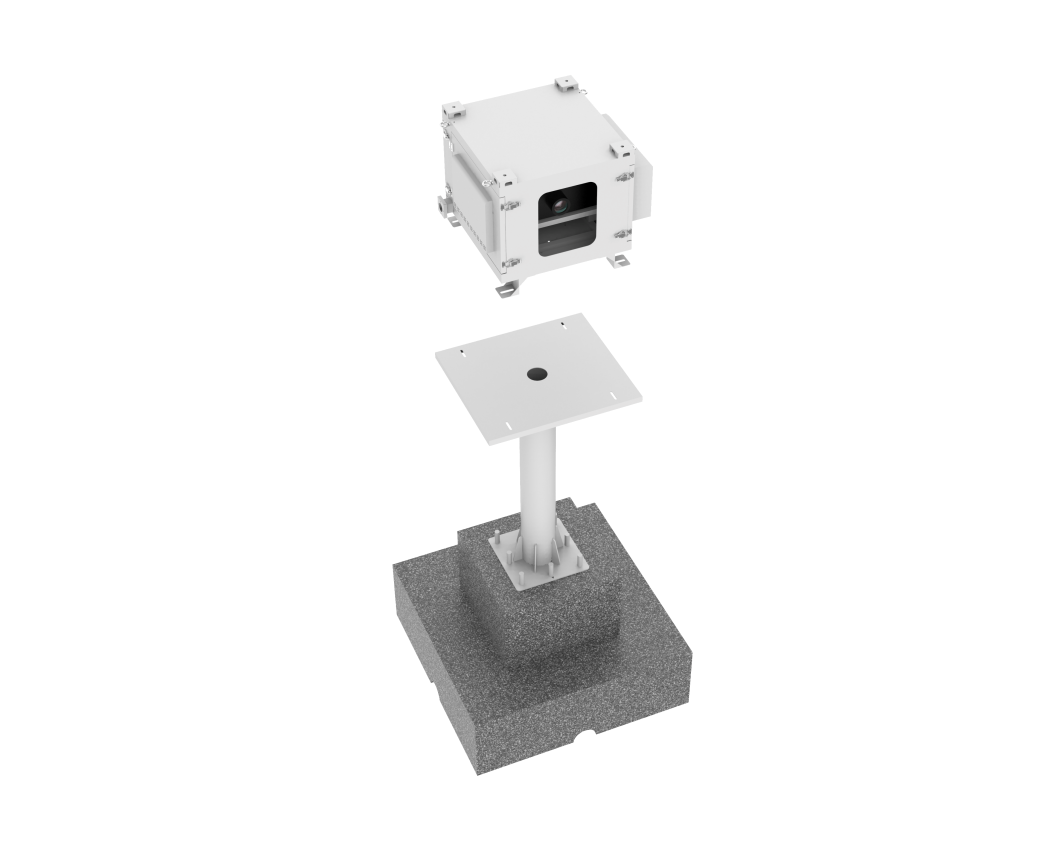

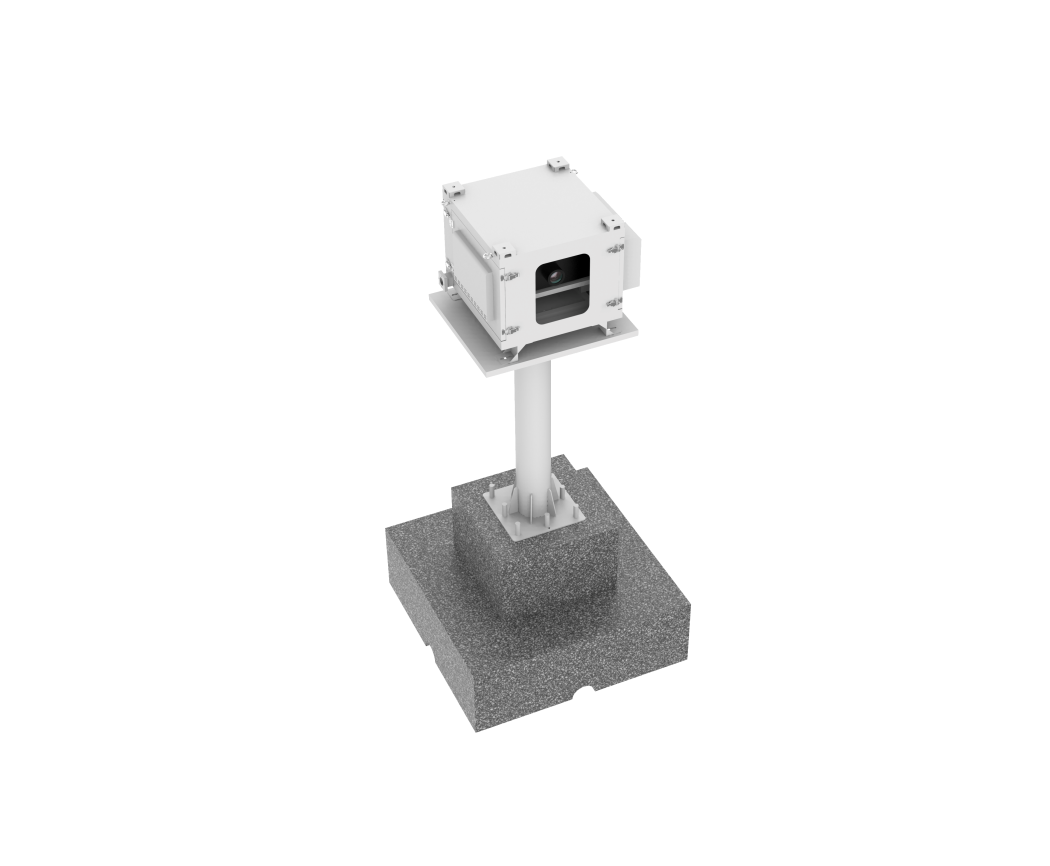

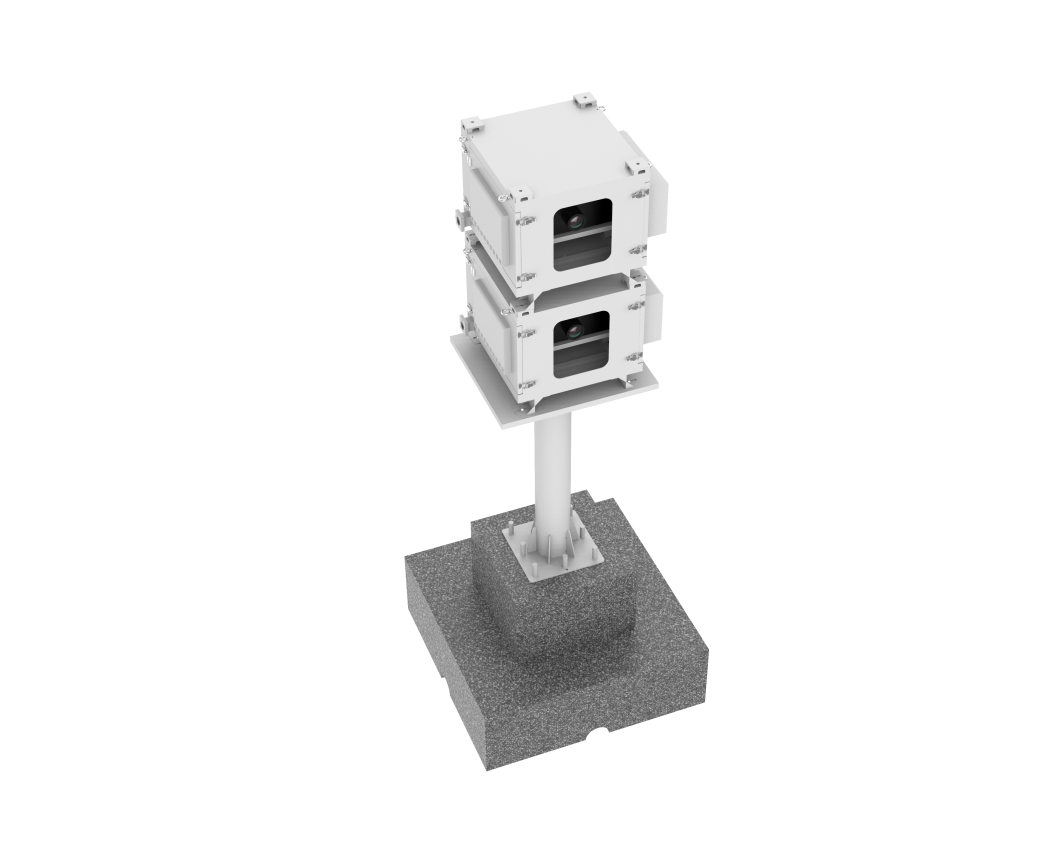

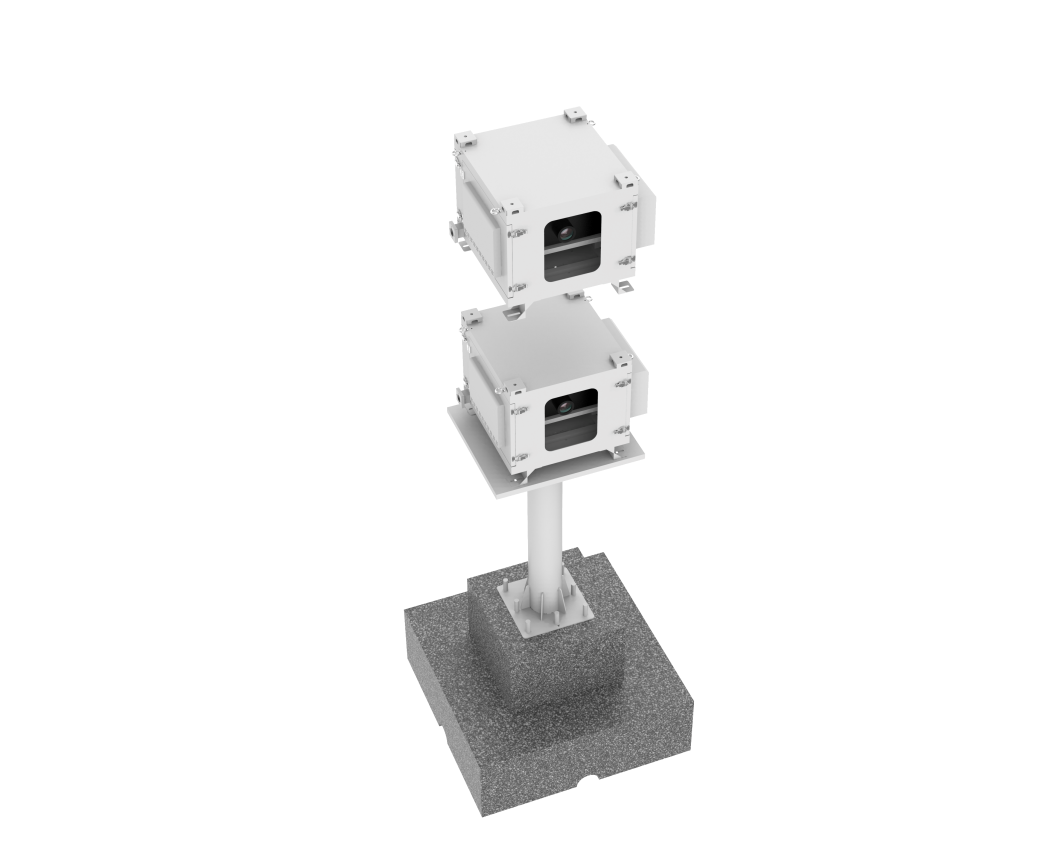

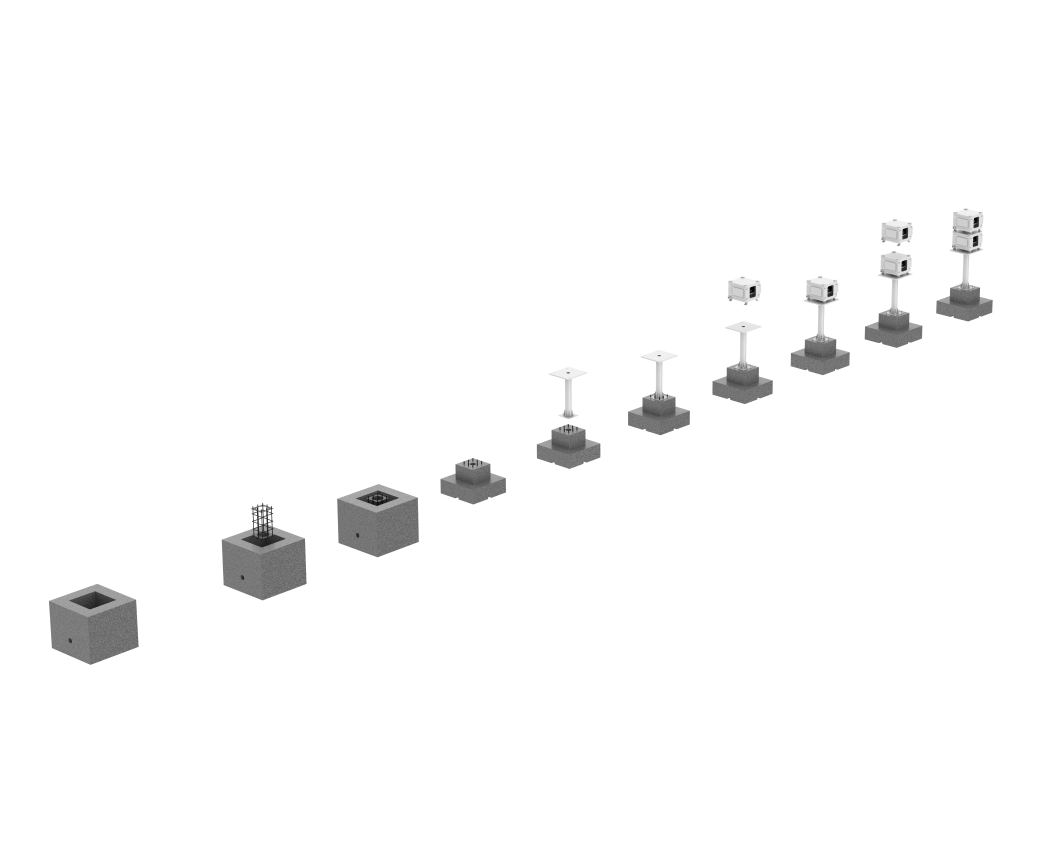

Installation Steps

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

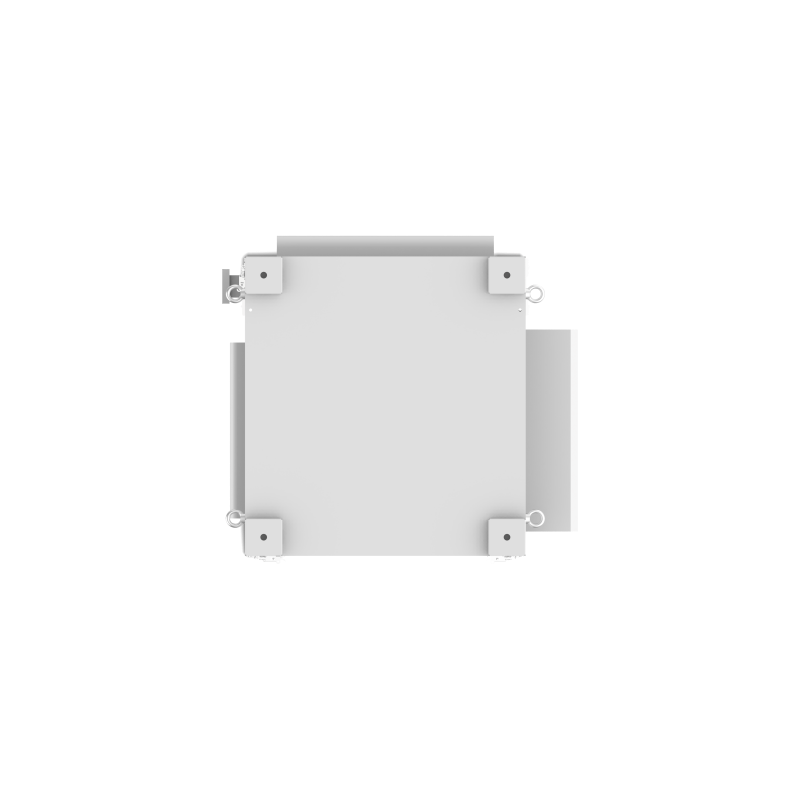

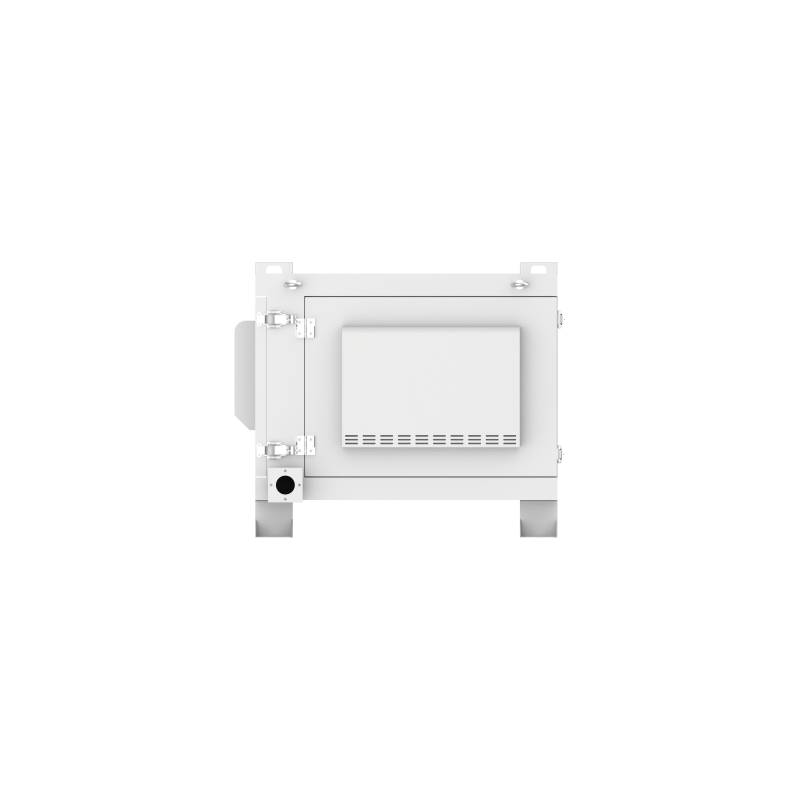

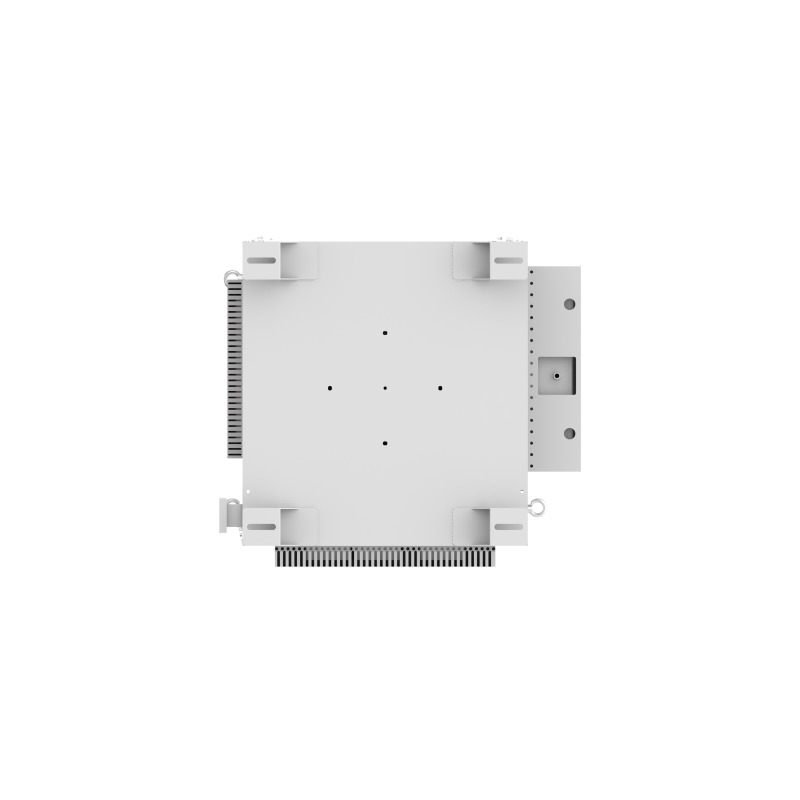

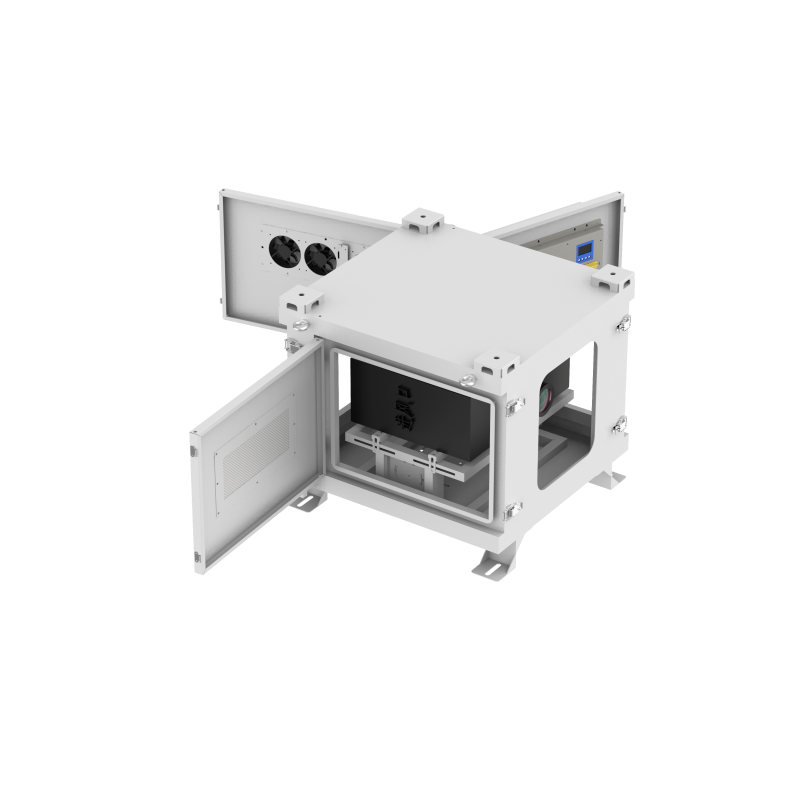

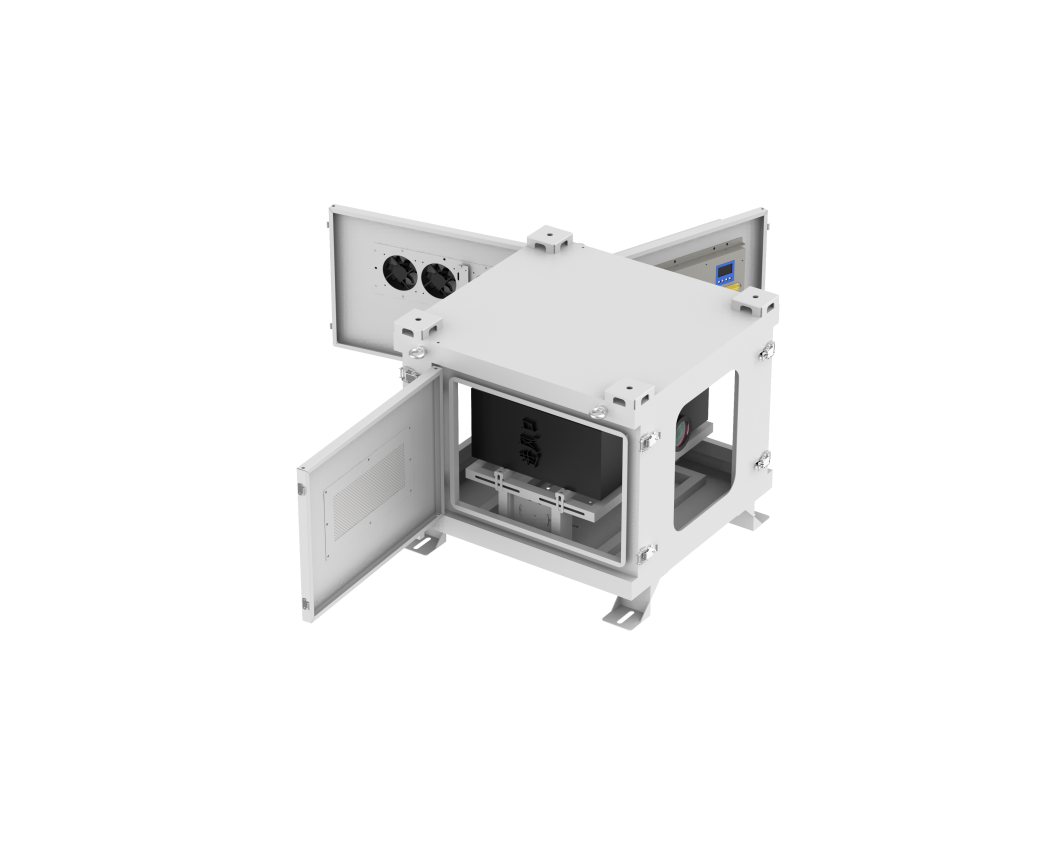

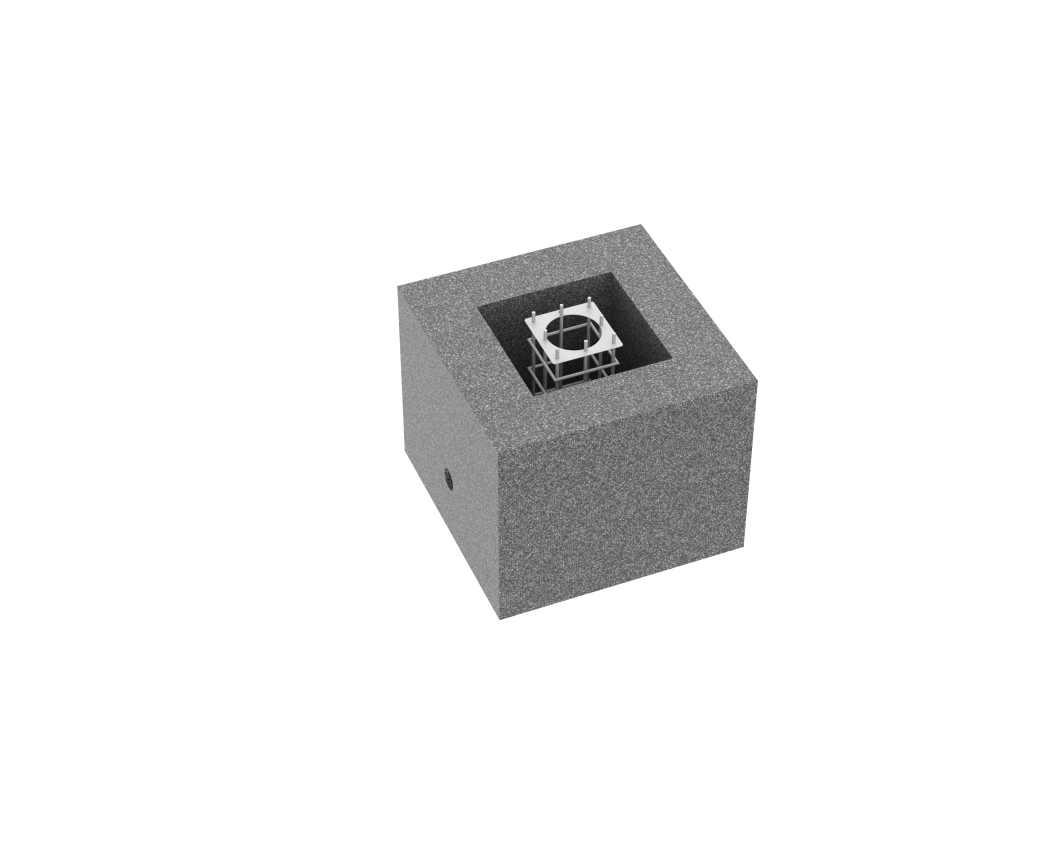

Internal structure of the waterproof box

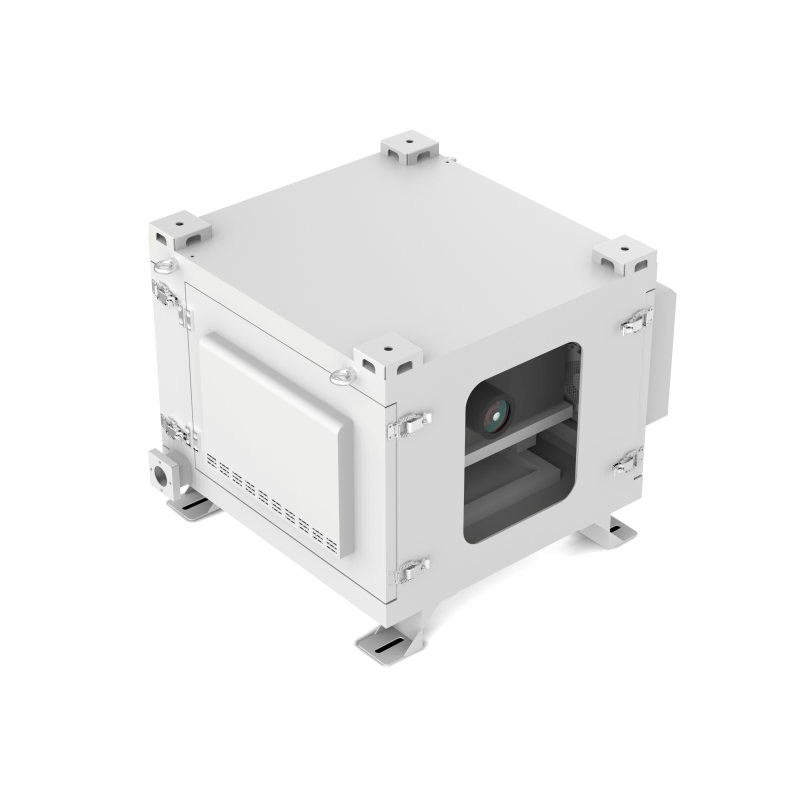

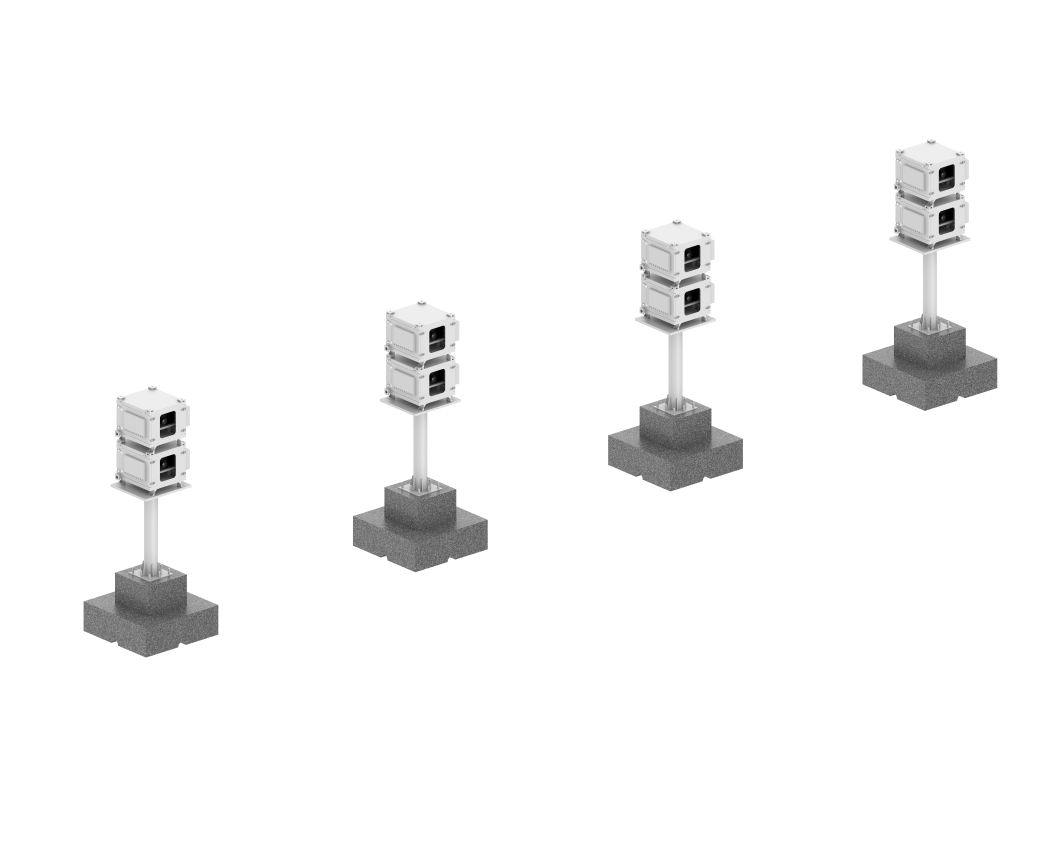

The waterproof box structure is divided into six main parts: the outer layer of the sheet metal body, the intelligent main control box, the maintenance waterproof door, the projector adjustment base, high-transparency optical glass, and stainless steel installation hanging rings for waterproof box adjustment. The placement method of the projector, the projection method, and the installation method of the waterproof box determine the overall structural design of the waterproof box. In addition to ensuring a stable working environment for the projector, the design of the waterproof box also takes into account the projection angle of the projector and its safety in public places.

Practical features of waterproof boxes

1. The waterproof box has functions such as waterproofing, dustproofing, corrosion resistance, anti-frosting, heating, and dehumidification.

2. The projector platform allows for linear angle adjustment (up to 10 degrees, with larger adjustment angles available upon customization).

3. The multi-door design facilitates easy installation and maintenance of the projector.

4. It is equipped with an internal hot air blower to ensure that there is no frost or fog on the projection surface.

5. The tripod and door use reinforced structures designed for strong wind solidification, and additional hanging protection ensures the safety of the waterproof box before and after installation.

6. Inside, it includes a 32A AC contactor, a 16A or 10A multifunctional socket.

7. The projection port uses optical ultra-white glass with a 95% light transmission rate.

Wind-cooling

Air-conditioning

Waterproof box material

Surface treatment