The growing demand for outdoor entertainment and commercial display solutions has made outdoor projector chassis an essential component for businesses investing in weather-resistant projection systems. B2B buyers face unique challenges when ordering these specialized enclosures in bulk, from ensuring proper environmental protection to managing cost-effective procurement strategies. Understanding the critical factors involved in bulk purchasing decisions can significantly impact project success and long-term operational efficiency.

Modern businesses require reliable protection for their projection equipment when deploying outdoor installations across multiple locations. The complexity of bulk ordering extends beyond simple quantity considerations, encompassing technical specifications, supplier reliability, and comprehensive project planning. Smart procurement decisions in this specialized market can result in substantial cost savings while ensuring consistent quality across all deployment sites.

Environmental Protection Requirements

Weather Resistance Standards

Outdoor projector chassis must meet stringent environmental protection standards to ensure equipment longevity and reliable performance. The IP rating system provides a standardized framework for evaluating ingress protection against dust and moisture. Most commercial applications require minimum IP65 rating, which guarantees complete dust protection and resistance to water jets from any direction.

Temperature extremes present additional challenges that B2B buyers must address when selecting chassis specifications. Quality enclosures incorporate thermal management systems including ventilation fans, heat sinks, and insulation materials designed to maintain optimal operating temperatures. The chassis should accommodate temperature ranges from negative twenty degrees Celsius to positive sixty degrees Celsius for year-round operation.

UV radiation resistance becomes crucial for installations exposed to direct sunlight over extended periods. Premium chassis materials include UV-stabilized polymers or powder-coated aluminum that prevent degradation, discoloration, and structural weakening. This protection ensures the enclosure maintains its protective properties and aesthetic appearance throughout its operational lifespan.

Corrosion and Chemical Resistance

Coastal environments and industrial locations expose outdoor projector chassis to corrosive elements that can compromise structural integrity. Marine-grade aluminum alloys and stainless steel components provide superior corrosion resistance compared to standard materials. These premium materials justify their higher initial cost through extended service life and reduced maintenance requirements.

Chemical resistance specifications become particularly important for installations near manufacturing facilities, airports, or urban areas with high pollution levels. The chassis coating system should resist common environmental contaminants including acid rain, salt spray, and industrial emissions. Regular testing and certification documentation from suppliers provide assurance of long-term performance in challenging environments.

Technical Specifications and Compatibility

Projector Accommodation Range

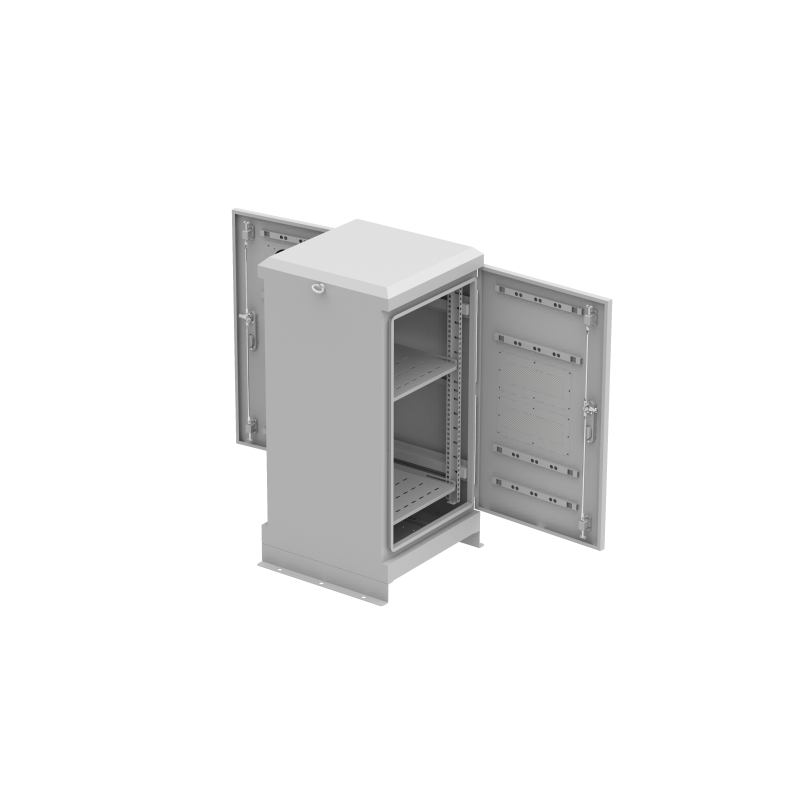

Bulk buyers must carefully evaluate the internal dimensions and mounting flexibility of outdoor projector chassis to ensure compatibility with their specific equipment models. Universal mounting systems that accommodate multiple projector brands and sizes provide valuable flexibility for organizations with diverse equipment inventories. Adjustable mounting brackets and cable management systems simplify installation while maintaining proper equipment alignment.

Lens access requirements vary significantly between projector models, necessitating chassis designs that provide adequate clearance and adjustment capabilities. Some installations require remote lens adjustment mechanisms or motorized positioning systems integrated within the chassis. These advanced features add complexity but enable precise projector alignment without accessing the internal components.

Cooling and ventilation requirements directly correlate with projector heat output and ambient operating conditions. High-lumen projectors generate substantial heat that requires active cooling systems within the chassis. Buyers should verify that the cooling capacity matches or exceeds the thermal requirements of their specific projector models to prevent overheating and premature equipment failure.

Power and Connectivity Infrastructure

Comprehensive power management systems within the outdoor projector chassis ensure reliable operation and protection against electrical surges. Integrated power distribution panels should include circuit breakers, surge suppressors, and power monitoring capabilities. These systems protect valuable projection equipment while providing diagnostic information for maintenance planning.

Network connectivity requirements continue expanding as projection systems integrate with building management systems and content distribution networks. Modern chassis designs incorporate weatherproof network connections, fiber optic interfaces, and wireless communication modules. These connectivity options enable remote monitoring, content updates, and system diagnostics without physical site access.

Supplier Evaluation and Quality Assurance

Manufacturing Standards and Certifications

Reputable suppliers maintain comprehensive quality management systems that ensure consistent manufacturing standards across bulk orders. ISO certification programs provide framework for quality control processes, material traceability, and continuous improvement initiatives. Buyers should request detailed information about supplier quality certifications and manufacturing facility capabilities.

Third-party testing and certification validate chassis performance claims and provide independent verification of specifications. UL listing, CE marking, and FCC compliance demonstrate adherence to safety and electromagnetic compatibility standards. These certifications reduce liability risks and ensure regulatory compliance across different installation jurisdictions.

Material certificates and test reports provide transparency regarding component specifications and performance characteristics. Quality suppliers provide detailed documentation including material certifications, environmental testing results, and warranty information. This documentation supports informed purchasing decisions and provides reference material for future maintenance planning.

Supply Chain Management and Logistics

Reliable supply chain management becomes critical for bulk orders requiring coordinated delivery schedules across multiple project sites. Established suppliers maintain adequate inventory levels and production capacity to fulfill large orders without compromising quality or delivery timelines. Buyers should evaluate supplier capacity and request detailed production schedules before committing to bulk purchase agreements.

Global supply chain disruptions have highlighted the importance of supplier diversification and contingency planning. Suppliers with multiple manufacturing locations and diverse component sourcing strategies provide greater resilience against supply chain interruptions. This redundancy ensures project continuity even when unexpected disruptions affect individual supply chain elements.

Cost Optimization Strategies

Volume Pricing and Negotiation Tactics

Bulk purchasing power enables significant cost reductions through volume pricing tiers and negotiated contract terms. Buyers should establish clear quantity requirements and delivery schedules to maximize negotiating leverage with suppliers. Long-term purchasing agreements often provide additional discounts while ensuring price stability for multi-phase projects.

Total cost of ownership analysis extends beyond initial purchase price to include installation, maintenance, and lifecycle costs. Premium outdoor projector chassis with superior materials and construction often provide better long-term value despite higher upfront costs. Detailed cost modeling helps buyers identify the optimal balance between initial investment and operational expenses.

Payment terms and financing options can significantly impact cash flow management for large bulk orders. Suppliers may offer extended payment terms, progressive billing schedules, or equipment financing programs. These financial arrangements enable buyers to optimize working capital while securing favorable pricing on bulk purchases.

Standardization Benefits

Standardizing on specific chassis models across multiple installations provides numerous operational advantages beyond initial cost savings. Maintenance teams become familiar with standardized equipment, reducing training requirements and service response times. Spare parts inventory management simplifies when dealing with identical chassis specifications across all deployment sites.

Procurement efficiency improves significantly when organizations establish preferred supplier relationships and standardized specifications. Repeat orders require less evaluation time and negotiation effort, enabling faster project execution. This efficiency translates into reduced administrative costs and improved project timelines for organizations with ongoing outdoor projection requirements.

Installation and Deployment Considerations

Site Preparation Requirements

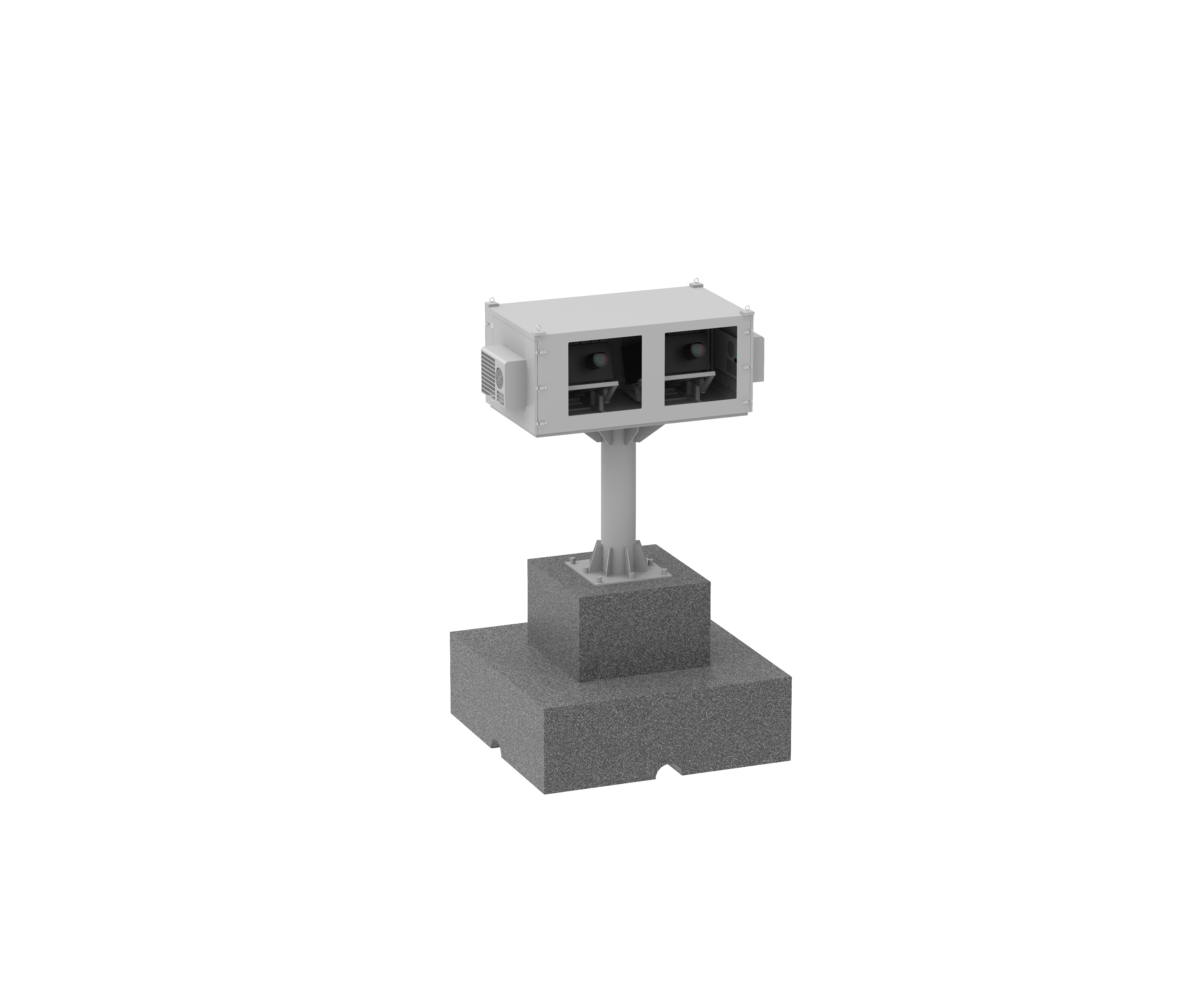

Proper site preparation ensures optimal performance and longevity of outdoor projector chassis installations. Foundation requirements vary based on chassis size, weight, and local environmental conditions. Concrete pads or mounting structures must provide stable support while accommodating thermal expansion and wind loading forces.

Electrical infrastructure planning requires careful coordination between chassis specifications and site electrical systems. Dedicated electrical circuits with appropriate capacity and protection devices ensure reliable operation and code compliance. Ground fault protection and surge suppression systems protect equipment and personnel safety in outdoor environments.

Access requirements for maintenance and service activities influence chassis placement and site design decisions. Adequate clearance around the chassis enables technician access for routine maintenance, equipment replacement, and emergency repairs. Security considerations may require additional access control measures to protect valuable projection equipment.

Commissioning and Testing Procedures

Comprehensive commissioning procedures validate proper installation and system performance before final acceptance. Testing protocols should verify environmental protection, thermal management, and electrical systems under actual operating conditions. These procedures identify and resolve installation issues before they impact operational performance.

Documentation requirements for commissioned systems include as-built drawings, test results, and operational procedures. This documentation supports ongoing maintenance activities and provides reference material for future system modifications. Proper documentation also ensures warranty compliance and facilitates troubleshooting when issues arise.

Maintenance and Lifecycle Management

Preventive Maintenance Programs

Structured preventive maintenance programs maximize the operational lifespan and reliability of outdoor projector chassis installations. Regular inspection schedules identify potential issues before they cause equipment failures or performance degradation. Maintenance activities include cleaning, seal inspection, ventilation system service, and electrical connection verification.

Seasonal maintenance requirements address the specific challenges posed by changing environmental conditions. Pre-winter preparations may include drainage system checks, heating element testing, and seal inspection. Summer preparation focuses on cooling system performance, ventilation cleaning, and thermal protection verification.

Maintenance documentation systems track service history, parts replacement, and performance trends across all chassis installations. This data enables predictive maintenance strategies and identifies common failure modes that may require design improvements or operational changes. Comprehensive maintenance records also support warranty claims and equipment lifecycle planning.

Upgrade and Modification Flexibility

Future-ready chassis designs accommodate technology upgrades and changing operational requirements without complete system replacement. Modular construction and standardized interfaces enable projector upgrades, cooling system improvements, and connectivity enhancements. This flexibility extends the useful life of the chassis investment while supporting evolving projection technology.

Retrofit capabilities become increasingly important as projection technology advances and operational requirements change. Chassis designs with adequate space allocation and flexible mounting systems accommodate equipment upgrades with minimal modification. This adaptability reduces long-term ownership costs and supports sustainable equipment management practices.

FAQ

What is the typical lead time for bulk outdoor projector chassis orders

Lead times for bulk orders typically range from 8-16 weeks depending on order quantity, customization requirements, and supplier capacity. Standard configurations may ship faster while custom specifications require additional manufacturing time. Buyers should communicate delivery requirements early in the procurement process to ensure adequate production planning.

How do I determine the appropriate IP rating for my installation environment

IP rating selection depends on specific environmental exposure conditions including precipitation levels, dust presence, and potential water contact. Coastal installations or areas with frequent severe weather require higher IP ratings such as IP66 or IP67. Consult with suppliers about environmental conditions to receive appropriate rating recommendations for your specific application.

What warranty coverage should I expect for outdoor projector chassis

Quality suppliers typically offer 2-5 year warranties covering manufacturing defects and material failures under normal operating conditions. Extended warranty options may be available for bulk purchases. Warranty coverage should include both chassis components and integrated systems such as cooling and electrical components. Review warranty terms carefully to understand coverage limitations and maintenance requirements.

Can outdoor projector chassis accommodate different projector brands and models

Many chassis designs feature universal mounting systems that accommodate multiple projector brands and sizes within specified dimensional ranges. Adjustable mounting brackets and flexible cable management systems provide compatibility with various equipment configurations. However, buyers should verify specific projector compatibility and may need custom mounting solutions for unusual equipment dimensions or requirements.