Sourcing reliable outdoor projector chassis from professional manufacturers requires careful consideration of multiple factors that directly impact performance, durability, and long-term cost effectiveness. The outdoor environment presents unique challenges including temperature fluctuations, moisture exposure, dust infiltration, and UV radiation that can severely compromise standard projection equipment. Professional-grade outdoor projector chassis solutions provide essential protection while maintaining optimal thermal management and accessibility for maintenance operations.

The global market for outdoor projection solutions has experienced significant growth as businesses, educational institutions, and entertainment venues increasingly adopt outdoor display technologies. This expansion has created both opportunities and challenges for procurement professionals seeking reliable chassis solutions. Understanding the technical specifications, manufacturing standards, and quality assurance processes becomes crucial when evaluating potential suppliers and ensuring successful project outcomes.

Essential Technical Specifications for Outdoor Protection

Environmental Resistance Standards

Professional outdoor projector chassis must meet stringent environmental resistance standards to ensure reliable operation across diverse climatic conditions. The IP rating system provides standardized measurements for ingress protection against solid particles and water infiltration. Most commercial outdoor applications require minimum IP65 certification, which guarantees complete dust protection and resistance to water jets from multiple directions.

Temperature cycling capability represents another critical specification that distinguishes professional-grade chassis from consumer alternatives. Industrial outdoor projector chassis typically operate within temperature ranges from -40°C to +70°C, accommodating extreme seasonal variations and direct solar exposure. This thermal tolerance requires specialized materials, gasket systems, and ventilation designs that maintain internal climate control while preventing condensation formation.

UV stability becomes particularly important for chassis materials and external coatings exposed to continuous sunlight. High-quality manufacturers utilize UV-resistant polymers, anodized aluminum finishes, and specialized paint systems that maintain structural integrity and aesthetic appearance over extended deployment periods. These protective measures prevent material degradation, color fading, and mechanical failure that commonly affect inferior products.

Thermal Management Systems

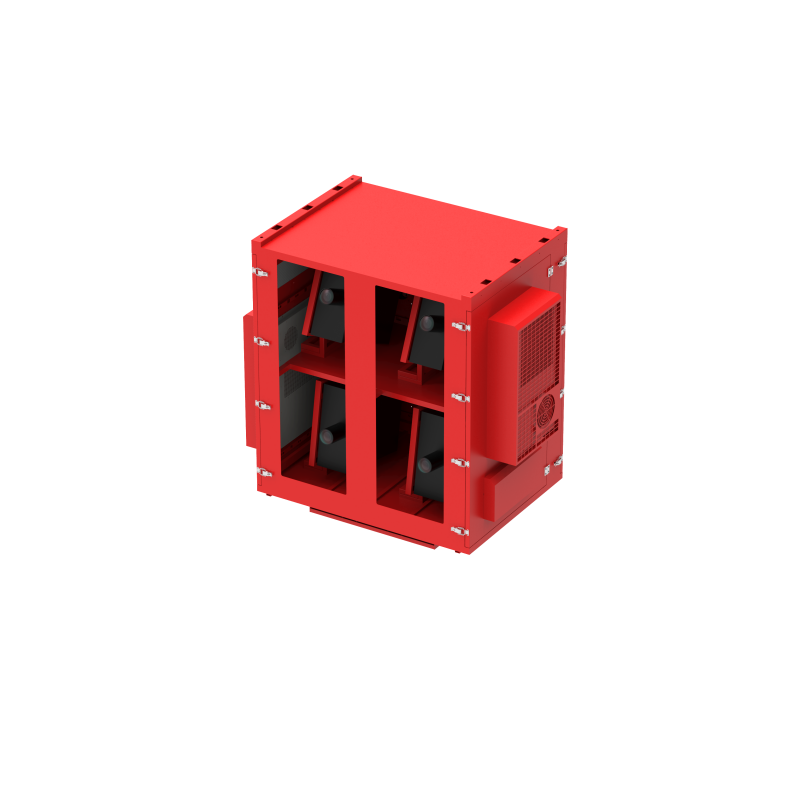

Effective thermal management distinguishes professional outdoor projector chassis from basic enclosure solutions. Advanced designs incorporate active cooling systems with temperature-controlled fans, heat exchangers, and intelligent airflow management to maintain optimal operating temperatures for sensitive projection components. These systems must balance cooling efficiency with dust filtration and moisture exclusion requirements.

Passive thermal management features include strategic ventilation placement, heat sink integration, and thermal barrier coatings that reduce solar heat gain. Professional manufacturers conduct extensive thermal modeling and testing to optimize air circulation patterns and eliminate hot spots that could compromise projector performance or component lifespan.

Condensation prevention mechanisms represent sophisticated engineering challenges requiring precise humidity control and surface temperature management. Quality chassis designs incorporate internal heating elements, moisture barriers, and desiccant systems that maintain dry internal environments even during extreme humidity conditions or rapid temperature changes.

Manufacturing Quality and Certification Standards

Material Selection and Construction Methods

Professional manufacturers utilize marine-grade aluminum alloys, stainless steel components, and engineering plastics specifically selected for outdoor durability and corrosion resistance. These materials undergo rigorous testing for tensile strength, impact resistance, and long-term weathering performance to ensure consistent quality across production batches.

Precision manufacturing processes including CNC machining, welded construction, and automated assembly ensure dimensional accuracy and consistent fit tolerances critical for weatherproof sealing. Advanced manufacturers implement quality management systems complying with ISO 9001 standards and maintain detailed documentation of material certificates, process controls, and inspection records.

Surface treatment processes such as powder coating, anodization, and galvanization provide additional corrosion protection and aesthetic enhancement. Professional-grade finishes undergo salt spray testing, UV exposure evaluation, and adhesion testing to verify long-term performance under harsh environmental conditions.

Testing and Validation Procedures

Comprehensive testing protocols validate outdoor projector chassis performance across multiple environmental and operational scenarios. Professional manufacturers conduct accelerated aging tests, thermal cycling evaluations, and vibration testing to simulate years of field exposure within controlled laboratory conditions.

Field testing programs involve deploying prototype chassis in diverse geographic locations and climatic zones to gather real-world performance data. This empirical validation process helps identify potential failure modes and guides design improvements before full production implementation.

Third-party certification from recognized testing laboratories provides independent verification of performance claims and compliance with industry standards. Certifications from UL, CSA, CE, and other regulatory bodies demonstrate commitment to safety, quality, and international market requirements.

Supplier Evaluation and Selection Criteria

Manufacturing Capabilities Assessment

Evaluating potential suppliers requires comprehensive assessment of manufacturing capabilities, production capacity, and quality control systems. Site visits to production facilities provide valuable insights into equipment sophistication, process automation levels, and workforce expertise that directly impact product quality and delivery reliability.

Production capacity analysis should consider both current output levels and scalability potential to accommodate future growth requirements. Suppliers with flexible manufacturing systems and established supply chain relationships typically offer better long-term partnership opportunities and responsive customer support.

Technical support capabilities including engineering consultation, custom design services, and field support availability represent important differentiating factors among competing suppliers. Manufacturers with dedicated technical teams and application expertise can provide valuable guidance throughout project planning and implementation phases.

Financial Stability and Business Reputation

Financial stability assessment helps ensure supplier longevity and continued support availability throughout product lifecycles. Credit evaluations, financial statements review, and industry reputation analysis provide important risk management information for strategic sourcing decisions.

Customer reference verification offers practical insights into supplier performance, delivery reliability, and post-sale support quality. Speaking directly with existing customers about their experiences helps validate supplier claims and identify potential concerns before contract commitment.

Industry certifications, professional memberships, and award recognition demonstrate supplier commitment to excellence and continuous improvement. Suppliers actively engaged in industry associations and standards development often possess deeper technical expertise and market awareness.

Cost Analysis and Value Engineering

Total Cost of Ownership Evaluation

Comprehensive cost analysis extends beyond initial purchase price to include installation, maintenance, and lifecycle replacement costs. Professional outdoor projector chassis with superior durability and reliability often provide better long-term value despite higher upfront investment compared to lower-quality alternatives.

Energy consumption considerations include both active cooling requirements and thermal efficiency impacts on projector operation. Well-designed chassis with effective passive cooling can reduce overall system energy consumption and associated operating costs over extended deployment periods.

Maintenance accessibility features such as removable panels, cable management systems, and component access ports can significantly reduce service costs and minimize downtime during routine maintenance operations. These design elements justify premium pricing through reduced operational complexity and lower total ownership costs.

Customization and Value-Added Services

Custom design capabilities allow suppliers to optimize chassis solutions for specific application requirements, environmental conditions, and integration constraints. Manufacturers offering comprehensive customization services can provide better overall value through improved performance and reduced system complexity.

Value-added services including installation support, training programs, and extended warranty coverage enhance overall purchase value and reduce project risk. Suppliers providing comprehensive service packages often deliver superior customer experiences and project outcomes.

Long-term partnership opportunities with established suppliers can yield additional benefits including preferential pricing, priority support, and collaborative product development initiatives. Building strategic relationships with quality suppliers creates competitive advantages and operational efficiency improvements.

Installation and Integration Considerations

Mounting and Structural Requirements

Professional outdoor projector chassis require robust mounting systems capable of withstanding wind loads, seismic forces, and thermal expansion cycles. Mounting hardware specifications must account for local building codes, environmental conditions, and structural load limitations of installation surfaces.

Accessibility requirements for maintenance operations influence chassis placement and mounting configurations. Optimal installations provide safe access for cleaning, filter replacement, and component servicing without requiring specialized equipment or extensive disassembly procedures.

Cable management and connectivity provisions must accommodate power distribution, data transmission, and control signals while maintaining weatherproof integrity. Professional chassis designs include sealed cable entry points, strain relief systems, and organized routing pathways that simplify installation and reduce failure risks.

System Integration and Compatibility

Compatibility verification ensures seamless integration between chassis systems and projection equipment from various manufacturers. Dimensional specifications, ventilation requirements, and interface standards must align with specific projector models and operational requirements.

Control system integration capabilities including remote monitoring, environmental sensors, and automated operational controls enhance system functionality and reduce maintenance requirements. Advanced chassis systems with integrated monitoring provide valuable operational data and predictive maintenance capabilities.

Future expansion considerations should account for technology upgrades, capacity increases, and evolving operational requirements. Modular chassis designs with standardized interfaces provide flexibility for future modifications without major system replacement.

FAQ

What IP rating is recommended for outdoor projector chassis in harsh environments

For harsh outdoor environments, IP65 or higher rating is recommended to ensure complete dust protection and resistance to high-pressure water jets. Applications in extremely harsh conditions such as coastal areas with salt spray or industrial environments may require IP66 or IP67 ratings for enhanced protection against temporary submersion and high-pressure cleaning operations.

How important is thermal management in outdoor projector chassis selection

Thermal management is critically important as it directly affects projector performance, component lifespan, and image quality. Inadequate cooling can cause thermal shutdown, reduced brightness, color shift, and premature component failure. Professional chassis with active cooling systems and intelligent temperature controls maintain optimal operating conditions and extend equipment life significantly compared to passive enclosures.

What factors should be considered when evaluating outdoor projector chassis manufacturers

Key evaluation factors include manufacturing quality certifications, environmental testing standards, material specifications, thermal management capabilities, customization options, technical support availability, financial stability, and customer references. Additionally, assess production capacity, delivery reliability, warranty terms, and long-term service commitments to ensure successful project outcomes and ongoing support.

How do I determine the appropriate size chassis for my specific projector model

Chassis sizing requires consideration of projector dimensions, ventilation clearances, cable routing space, and maintenance access requirements. Professional manufacturers provide compatibility matrices and dimensional guidelines for specific projector models. Additionally, account for thermal expansion, future upgrade possibilities, and any additional equipment such as media players or control systems that may need housing within the same chassis.

Table of Contents

- Essential Technical Specifications for Outdoor Protection

- Manufacturing Quality and Certification Standards

- Supplier Evaluation and Selection Criteria

- Cost Analysis and Value Engineering

- Installation and Integration Considerations

-

FAQ

- What IP rating is recommended for outdoor projector chassis in harsh environments

- How important is thermal management in outdoor projector chassis selection

- What factors should be considered when evaluating outdoor projector chassis manufacturers

- How do I determine the appropriate size chassis for my specific projector model