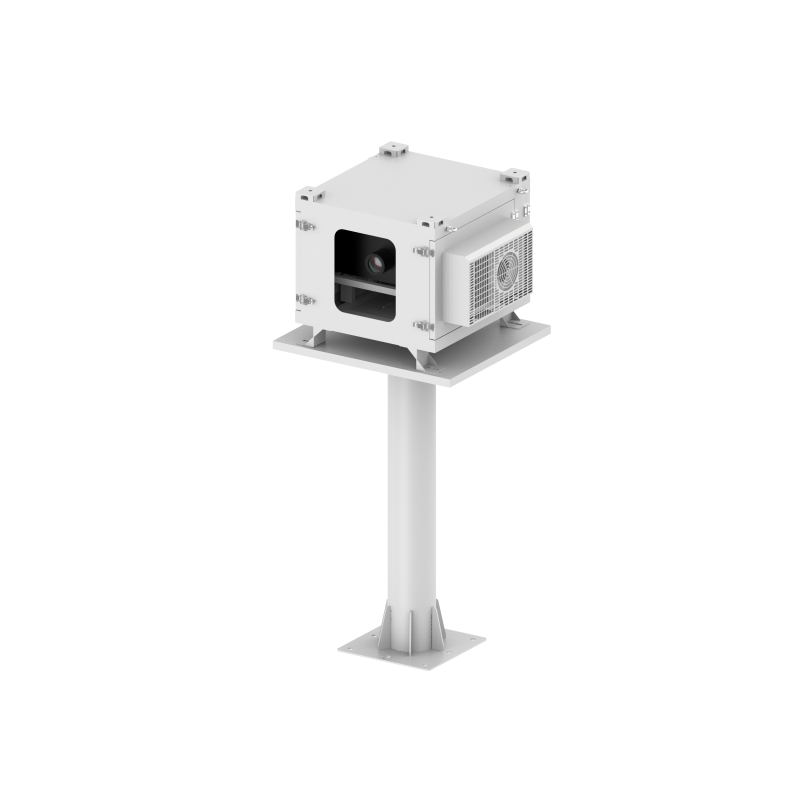

Installing projection equipment outdoors presents unique challenges that require specialized protection solutions. An outdoor projector cabinet serves as the critical barrier between your valuable projection equipment and harsh environmental conditions, ensuring reliable performance year-round. Understanding the essential features of these protective enclosures can make the difference between a successful outdoor installation and costly equipment failures.

Modern outdoor projection applications span from entertainment venues and sports facilities to digital signage and educational institutions. Each application demands robust protection that maintains optimal operating conditions while providing easy maintenance access. The right enclosure solution protects against weather elements, temperature fluctuations, dust infiltration, and security threats that could compromise equipment functionality.

Environmental Protection and Weatherproofing

Water and Moisture Resistance

Superior water resistance represents the cornerstone of effective outdoor projection protection. Quality enclosures feature multiple sealing layers including gasket seals, compression fittings, and drainage systems that prevent moisture infiltration. The IP rating system provides standardized measurements for protection levels, with IP65 or higher ratings recommended for outdoor installations exposed to direct weather conditions.

Condensation management requires active moisture control systems beyond basic sealing. Internal humidity sensors trigger ventilation systems or dehumidification units when moisture levels exceed safe thresholds. This proactive approach prevents internal condensation that can damage sensitive electronic components even when external sealing remains intact.

Drainage features ensure that any moisture that does penetrate the enclosure can exit safely without accumulating around equipment. Strategically placed drain holes with protective covers allow water evacuation while maintaining overall enclosure integrity. These systems work in conjunction with sloped internal surfaces that direct moisture away from critical components.

UV and Solar Protection

Extended exposure to ultraviolet radiation degrades both enclosure materials and internal components over time. High-quality outdoor cabinets incorporate UV-resistant materials such as powder-coated aluminum, stainless steel, or specialized polymers that maintain structural integrity under constant solar exposure. These materials prevent warping, cracking, or color degradation that could compromise protection effectiveness.

Reflective surfaces and thermal barriers reduce heat absorption from direct sunlight, maintaining cooler internal temperatures. White or light-colored finishes reflect solar radiation more effectively than darker alternatives, while specialized coatings can provide additional thermal management benefits. Internal insulation layers create thermal barriers that prevent external temperature variations from affecting equipment performance.

Optical window protection requires specialized attention to prevent UV damage to projection lenses and internal optics. High-quality optical glass or acrylic windows with UV-filtering properties protect sensitive components while maintaining optical clarity. Anti-reflective coatings minimize glare and optical distortion that could impact projection quality.

Temperature Control and Thermal Management

Cooling System Integration

Active cooling systems maintain optimal operating temperatures for projection equipment regardless of external conditions. Multiple cooling approaches include forced air circulation, heat exchangers, and refrigeration systems depending on environmental demands and equipment specifications. Properly sized cooling capacity prevents overheating while minimizing energy consumption and operational costs.

Ventilation design creates effective airflow patterns that remove heat generated by projection equipment while preventing dust and moisture infiltration. Intake and exhaust fan placement, combined with internal airflow guides, ensures consistent temperature distribution throughout the enclosure. Filter systems protect cooling components from environmental contaminants while maintaining airflow efficiency.

Temperature monitoring and control systems provide automated thermal management with alarm capabilities for extreme conditions. Digital thermostats maintain precise temperature ranges while data logging capabilities track performance trends over time. Remote monitoring options enable proactive maintenance and immediate response to thermal issues before equipment damage occurs.

Insulation and Thermal Barriers

Multi-layer insulation systems create effective thermal barriers between external environmental conditions and internal equipment spaces. Closed-cell foam insulation, reflective barriers, and air gaps work together to minimize heat transfer while maintaining structural integrity. Proper insulation placement prevents thermal bridging that could create hot or cold spots within the enclosure.

Thermal mass management involves selecting enclosure materials and configurations that buffer temperature fluctuations naturally. Heavy-gauge metal construction provides thermal stability while internal thermal mass elements can store and release heat gradually to maintain consistent temperatures. This approach reduces cooling system workload and improves energy efficiency.

Heating elements become necessary in extremely cold climates to prevent equipment damage from freezing temperatures. Integrated heating systems with thermostatic control maintain minimum operating temperatures while preventing condensation formation during warm-up cycles. Heating distribution ensures uniform temperature maintenance throughout the entire enclosure volume.

Security Features and Access Control

Physical Security Measures

Robust construction materials and reinforced mounting systems protect valuable projection equipment from theft and vandalism attempts. Heavy-duty steel or aluminum construction with reinforced corners and mounting points provides physical barrier protection that deters casual theft attempts. Tamper-evident fasteners and security screws require specialized tools for access, adding additional security layers.

Locking mechanisms range from basic key locks to advanced electronic access control systems depending on security requirements and site conditions. Multi-point locking systems distribute force across multiple contact points, making forced entry more difficult. Electronic locks enable access logging and remote control capabilities while maintaining physical security when power systems fail.

Mounting security prevents entire enclosure removal through integrated anchoring systems and anti-theft mounting hardware. Concealed mounting points and reinforced attachment systems make enclosure removal extremely difficult without proper tools and authorization. Security cables and anchor points provide additional theft deterrence for high-risk installations.

Access Control and Monitoring

Controlled access systems ensure that only authorized personnel can reach projection equipment for maintenance or operation. Electronic access logs track entry attempts and successful access events, providing security audit trails for sensitive installations. Biometric systems, key cards, or digital keypads offer various levels of access control sophistication.

Intrusion detection systems provide immediate alerts when unauthorized access attempts occur. Vibration sensors, door position monitors, and motion detectors within the enclosure trigger alarm systems that notify security personnel or monitoring services. Integration with existing security infrastructure enables coordinated response to security events.

Remote monitoring capabilities allow security oversight without physical presence at installation sites. Internet-connected monitoring systems provide real-time status updates, access logs, and alarm notifications to authorized personnel regardless of location. Camera integration enables visual verification of access events and equipment status confirmation.

Maintenance Access and Serviceability

Equipment Access Design

Thoughtful access design enables efficient maintenance procedures while maintaining environmental protection when enclosures are closed. Hinged doors with multi-point locking provide wide opening access for equipment installation and major maintenance procedures. Gas struts or hydraulic supports hold doors open securely during service operations while preventing accidental closure.

Internal layout optimization ensures that all equipment components remain accessible for routine maintenance without requiring complete equipment removal. Sliding equipment mounts, removable panels, and service clearances allow technicians to perform filter changes, cleaning, and minor repairs efficiently. Cable management systems keep wiring organized and accessible while preventing damage during service procedures.

Tool storage and work surface integration provides technicians with convenient access to necessary equipment during maintenance procedures. Built-in tool holders, parts storage compartments, and fold-down work surfaces reduce maintenance time while ensuring proper tool security. Adequate lighting systems illuminate work areas for safe and efficient service operations.

Filter and Component Access

Easy filter access enables regular maintenance without compromising enclosure integrity or requiring specialized tools. Quick-release filter housings with external access panels allow filter replacement without opening main enclosure compartments. Filter monitoring systems track usage hours and contamination levels to optimize replacement scheduling and maintain optimal air quality.

Component modularity enables field replacement of critical systems without requiring complete enclosure disassembly. Plug-and-play connections for cooling systems, control modules, and monitoring equipment reduce maintenance complexity and minimize downtime during repairs. Standardized mounting interfaces ensure component compatibility across different equipment configurations.

Diagnostic access ports provide connection points for testing equipment and monitoring systems without requiring internal access. External diagnostic connections enable performance verification, troubleshooting, and system optimization while maintaining environmental sealing. Data logging capabilities track system performance trends to enable predictive maintenance scheduling.

Power and Connectivity Infrastructure

Electrical System Integration

Comprehensive electrical systems provide clean, stable power distribution for projection equipment and supporting systems within the enclosure. Surge protection devices safeguard sensitive electronics from power quality issues while uninterruptible power supply integration maintains operation during brief power interruptions. Electrical panel organization enables safe maintenance procedures with clearly labeled circuits and proper disconnect procedures.

Power conditioning systems ensure optimal electrical quality for sensitive projection equipment while managing power factor and harmonic distortion issues. Voltage regulation maintains consistent power delivery despite utility fluctuations while power monitoring systems track consumption patterns and identify potential electrical issues before equipment damage occurs.

An outdoor projector cabinet requires specialized electrical systems designed for harsh environmental conditions with appropriate weatherproofing and safety measures. NEMA-rated electrical components and proper grounding systems ensure electrical safety while maintaining reliable operation in challenging outdoor environments.

Communication and Control Systems

Network connectivity enables remote monitoring and control capabilities for projection systems and enclosure environmental controls. Ethernet connections, wireless communication options, and cellular backup systems ensure consistent connectivity regardless of site infrastructure limitations. Network security measures protect against unauthorized access while maintaining operational connectivity.

Control system integration allows centralized management of projection equipment, environmental systems, and security features through unified interfaces. Programmable logic controllers coordinate multiple system functions while providing alarm management and automated response capabilities. Integration with building management systems enables comprehensive facility monitoring and control.

Cable management systems organize power, data, and control wiring while protecting connections from environmental exposure and physical damage. Strain relief systems prevent cable damage from thermal expansion, vibration, and maintenance activities while maintaining proper cable routing throughout the enclosure. Expansion capabilities accommodate future system upgrades without requiring major infrastructure modifications.

FAQ

What IP rating should I look for in an outdoor projector enclosure

For most outdoor applications, look for an IP65 rating or higher, which provides complete protection against dust ingress and protection against water jets from any direction. In extremely harsh environments with heavy rain or potential flooding, consider IP66 or IP67 ratings for enhanced water protection. The specific rating needed depends on your local climate conditions and installation location exposure levels.

How important is active cooling versus passive cooling for outdoor projector cabinets

Active cooling becomes essential in most outdoor installations due to the combination of equipment heat generation and external environmental temperatures. While passive cooling through insulation and ventilation may work in mild climates, active systems provide precise temperature control and prevent overheating damage in challenging conditions. The investment in active cooling systems typically pays for itself through extended equipment life and reduced failure rates.

Can I retrofit an existing outdoor enclosure for projector use

Retrofitting existing enclosures is possible but requires careful evaluation of thermal management, power infrastructure, and environmental sealing capabilities. Existing enclosures often lack the specialized features needed for projection equipment protection, such as optical windows, precise temperature control, and vibration isolation. Purpose-built projector enclosures typically provide better long-term reliability and lower total cost of ownership compared to retrofit solutions.

What maintenance schedule should I follow for outdoor projector cabinet systems

Establish a comprehensive maintenance schedule including monthly visual inspections, quarterly filter replacements, semi-annual deep cleaning, and annual system performance evaluations. Environmental conditions at your specific site may require more frequent attention, particularly for filter systems and sealing integrity. Remote monitoring systems can help optimize maintenance timing based on actual operating conditions rather than fixed schedules, reducing unnecessary service visits while ensuring optimal protection.