Modern projection technology has evolved dramatically, enabling businesses and organizations to deploy high-quality display solutions in challenging outdoor environments. However, exposing expensive projection equipment to harsh weather conditions without proper protection can result in catastrophic damage and costly replacements. An outdoor projector cabinet serves as the critical barrier between sensitive electronic components and the relentless forces of nature, ensuring reliable performance regardless of environmental conditions.

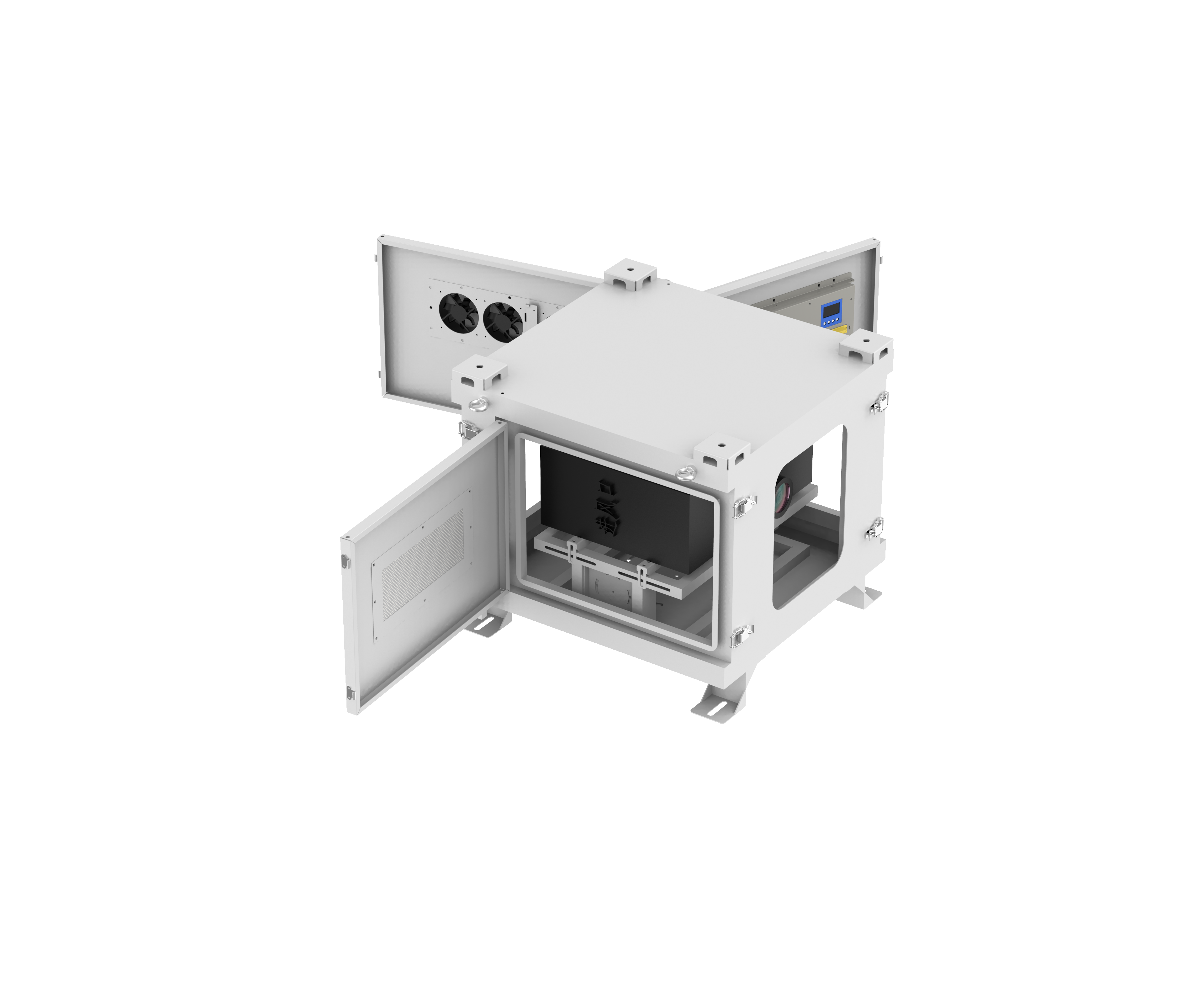

Professional-grade protective enclosures utilize advanced engineering principles to create an impenetrable shield against moisture infiltration and particulate contamination. These specialized housing solutions incorporate multiple layers of defense, including precision-machined sealing systems, advanced ventilation controls, and ruggedized construction materials designed to withstand extreme temperature fluctuations, torrential rainfall, and abrasive dust particles.

The investment in proper protective equipment pays substantial dividends through extended equipment lifespan, reduced maintenance costs, and uninterrupted operational reliability. Organizations deploying outdoor projection systems without adequate protection frequently encounter premature equipment failure, requiring expensive repairs or complete system replacements that could have been avoided through proactive protective measures.

Advanced Weatherproofing Technologies

Multi-Layer Sealing Systems

Professional outdoor projector cabinet designs incorporate sophisticated sealing mechanisms that create multiple barriers against water penetration. Primary sealing elements include precision-molded gaskets manufactured from marine-grade materials that maintain elasticity across extreme temperature ranges. These gaskets compress uniformly when the cabinet is sealed, creating an airtight barrier that prevents even microscopic water droplets from entering the interior space.

Secondary sealing systems employ overlapping joint configurations that redirect water flow away from critical entry points. Advanced designs integrate drainage channels and weep holes strategically positioned to evacuate any moisture that might penetrate the primary seal, ensuring that water cannot accumulate within the enclosure structure.

Tertiary protection involves internal moisture management systems, including desiccant chambers and humidity monitoring sensors that maintain optimal internal conditions even during prolonged exposure to high-humidity environments.

Ingress Protection Standards

The effectiveness of weatherproofing systems is quantified through internationally recognized Ingress Protection ratings that specify exact protection levels against solid particles and liquids. IP66-rated enclosures provide complete protection against dust infiltration and powerful water jets from any direction, making them suitable for the most demanding outdoor applications.

Higher-tier protection levels, such as IP67 and IP68 ratings, offer temporary or continuous submersion resistance, essential for installations in flood-prone areas or locations subject to severe storm conditions. These ratings represent rigorous testing protocols that verify protection performance under standardized conditions.

Professional installations require careful consideration of specific environmental challenges to select appropriate protection levels. Coastal installations face salt spray corrosion, while desert environments present extreme temperature cycling and abrasive sand particles that demand specialized protection strategies.

Dust Prevention Mechanisms

Filtration and Ventilation Systems

Effective dust protection requires sophisticated air management systems that maintain internal pressure differentials while preventing particulate infiltration. Advanced outdoor projector cabinet designs incorporate multi-stage filtration systems featuring progressively finer filter media that capture particles ranging from large debris down to microscopic dust.

Primary filtration stages utilize coarse mesh screens that block insects, leaves, and large debris while allowing adequate airflow for thermal management. Secondary filtration employs pleated media filters with MERV ratings appropriate for the specific installation environment, capturing fine particulates that could interfere with optical components or cooling systems.

Advanced systems integrate HEPA-grade filtration for ultra-clean internal environments, essential for high-precision optical equipment or installations in extremely dusty conditions such as construction sites or mining operations.

Positive Pressure Maintenance

Maintaining slight positive pressure within the enclosure creates an active barrier against dust infiltration through minor seal imperfections or cable entry points. Controlled ventilation fans generate consistent internal pressure that forces air outward through any potential leak paths, preventing external contaminants from entering the protected space.

Pressure regulation systems monitor internal conditions continuously, adjusting fan speeds automatically to maintain optimal pressure differentials regardless of external wind conditions or temperature variations that might affect natural air circulation patterns.

Smart pressure management systems incorporate multiple sensors and automated controls that optimize energy consumption while maintaining protection effectiveness, reducing operational costs and extending equipment lifespan.

Thermal Management Solutions

Heat Dissipation Strategies

High-performance projectors generate substantial heat during operation, requiring sophisticated thermal management systems that maintain safe operating temperatures while preserving weatherproof integrity. Advanced cooling solutions balance heat removal efficiency with protection requirements through innovative heat exchanger designs and intelligent airflow management.

Sealed heat exchangers transfer internal heat to external cooling systems without compromising cabinet integrity, utilizing specialized thermal interface materials and optimized fin geometries that maximize heat transfer efficiency within compact enclosure dimensions.

Active cooling systems employ variable-speed fans controlled by multiple temperature sensors that respond dynamically to changing thermal loads, ensuring optimal component temperatures while minimizing energy consumption and acoustic emissions.

Insulation and Temperature Control

Professional enclosures incorporate multi-layer insulation systems that minimize external temperature influences on internal conditions, reducing thermal cycling stress on sensitive electronic components. Advanced insulation materials provide superior thermal resistance while maintaining moisture barrier properties essential for long-term protection.

Integrated heating elements prevent condensation formation during cold weather conditions, maintaining internal temperatures above dew point levels that could cause moisture accumulation on optical surfaces or electronic circuits.

Smart temperature control systems monitor both internal and external conditions continuously, activating heating or cooling systems as needed to maintain optimal operating environments regardless of ambient weather conditions.

Material Engineering and Construction

Corrosion-Resistant Materials

Cabinet construction materials must withstand prolonged exposure to corrosive elements including salt spray, industrial pollutants, and ultraviolet radiation without degrading protective performance. Marine-grade aluminum alloys provide exceptional strength-to-weight ratios while resisting corrosion through natural oxide layer formation and optional anodizing treatments.

Stainless steel components offer superior corrosion resistance for critical structural elements and hardware, particularly in coastal or industrial environments where standard materials would fail rapidly. Specialized coatings and surface treatments extend material lifespan further while maintaining aesthetic appearance.

Advanced polymer composites combine lightweight properties with exceptional chemical resistance, making them ideal for specialized applications where traditional metals might prove inadequate or excessively heavy for mounting structures.

Structural Integrity and Durability

Robust construction methods ensure cabinet integrity under extreme loading conditions including high winds, thermal expansion, and seismic activity. Welded joints and reinforcement structures distribute loads evenly while maintaining seal integrity under mechanical stress.

Engineering analysis and finite element modeling optimize structural designs for specific environmental conditions, ensuring adequate safety margins while minimizing material usage and overall system weight.

Quality manufacturing processes including precision machining, controlled welding parameters, and comprehensive testing protocols ensure consistent performance across production runs and extended service life under demanding conditions.

Installation and Maintenance Considerations

Proper Installation Techniques

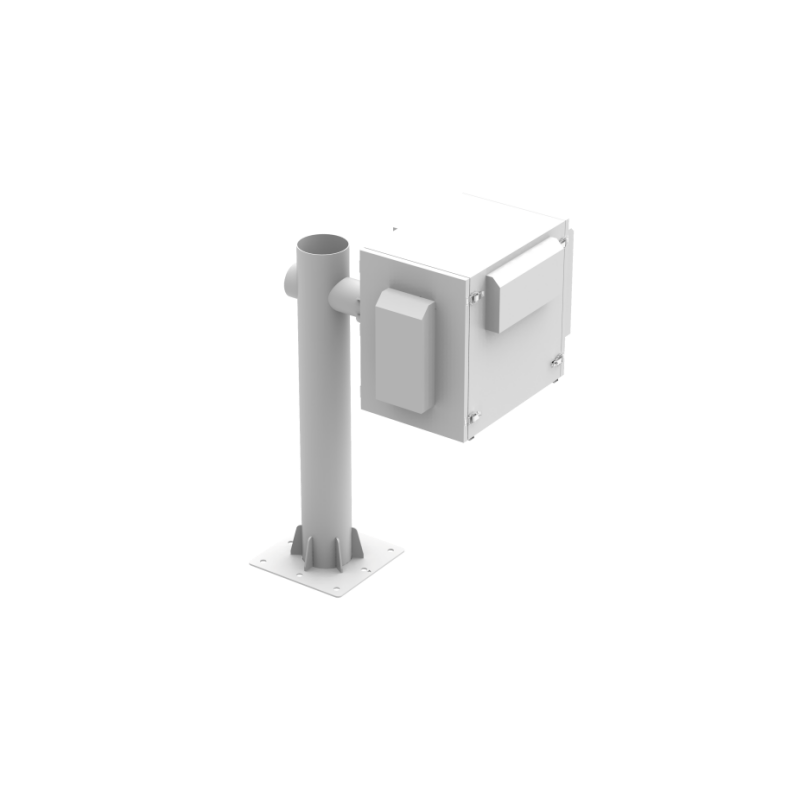

Successful outdoor projector cabinet installations require careful attention to mounting orientation, drainage considerations, and cable management to maintain protection effectiveness throughout the system lifecycle. Proper mounting angle ensures water runoff while providing optimal viewing angles for projection applications.

Cable entry systems must maintain weatherproof integrity while allowing necessary connections for power, video signals, and control systems. Advanced cable glands and conduit systems provide reliable sealing around varying cable diameters while accommodating future modifications or additions.

Site preparation includes adequate foundation design, proper grounding systems, and consideration of local building codes and wind load requirements that affect installation safety and longevity.

Preventive Maintenance Protocols

Regular maintenance schedules ensure continued protection effectiveness through systematic inspection and replacement of wear components before failure occurs. Filter replacement intervals depend on environmental conditions but typically range from quarterly to annual cycles.

Seal inspection and lubrication maintain weatherproof integrity while preventing premature degradation from thermal cycling and mechanical stress. Documentation of maintenance activities enables trend analysis and optimization of service intervals.

Proactive monitoring systems alert maintenance personnel to developing issues before they compromise protection, enabling scheduled interventions that prevent costly emergency repairs or equipment damage.

FAQ

What IP rating is required for outdoor projector cabinets in heavy rain conditions

For heavy rain conditions, an IP65 rating provides adequate protection against water jets from any direction, while IP66 offers superior protection against powerful water jets. For extreme weather applications or flood-prone areas, IP67 or IP68 ratings ensure protection even during temporary submersion events.

How often should filters be replaced in dusty environments

Filter replacement frequency depends on environmental dust loading, but typical intervals range from monthly in extremely dusty conditions to quarterly in moderate environments. Monitoring pressure differentials across filters provides objective indicators of when replacement is necessary, optimizing maintenance schedules and protection effectiveness.

Can outdoor projector cabinets operate in extreme temperature ranges

Professional outdoor projector cabinets typically operate reliably in temperature ranges from -40°F to +140°F through integrated thermal management systems. Specialized applications may require custom solutions for more extreme conditions, including arctic installations or desert environments with extreme temperature cycling.

What maintenance is required to ensure long-term weather protection

Essential maintenance includes regular seal inspection and lubrication, filter replacement according to environmental conditions, drainage system cleaning, and verification of positive pressure systems. Annual comprehensive inspections should include torque verification of fasteners, electrical connection inspection, and performance testing of all protection systems.