The evolution of outdoor electronics protection has reached a critical juncture where standard enclosures no longer meet the demanding requirements of modern applications. Custom sheet metal fabrication has emerged as the definitive solution for creating outdoor cabinets that withstand harsh environmental conditions while maintaining optimal functionality. This specialized manufacturing approach enables the creation of durable, weatherproof enclosures that protect valuable equipment from moisture, temperature fluctuations, and physical damage.

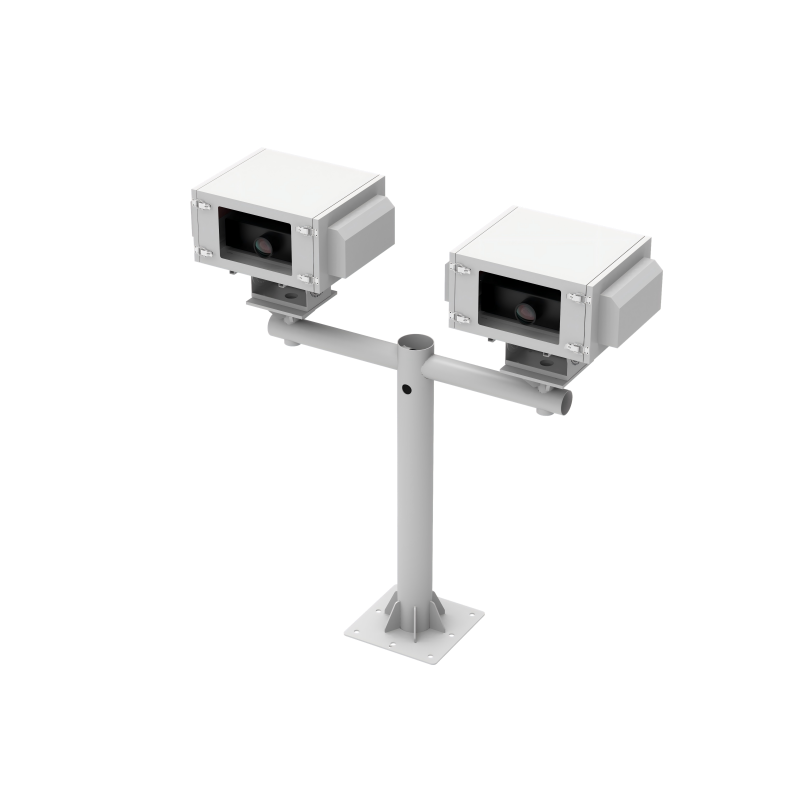

Industries ranging from telecommunications to digital signage rely heavily on robust outdoor enclosure solutions to protect their infrastructure investments. The precision and adaptability offered by custom sheet metal fabrication processes ensure that each cabinet meets specific dimensional, environmental, and operational requirements. Unlike generic alternatives, these tailored solutions provide superior protection while accommodating unique mounting configurations and cable management needs.

Understanding the Environmental Challenges for Outdoor Cabinets

Weather Resistance Requirements

Outdoor cabinets face an unrelenting barrage of environmental threats that can compromise electronic equipment functionality. Rain, snow, and humidity create moisture infiltration risks that standard enclosures cannot adequately address. Temperature variations ranging from scorching summer heat to freezing winter conditions demand materials and construction methods that maintain structural integrity across extreme thermal cycles.

Wind-driven debris, hail, and UV radiation add additional layers of complexity to outdoor cabinet design requirements. Custom sheet metal fabrication addresses these challenges through precisely engineered materials selection and protective surface treatments. The manufacturing process allows for strategic reinforcement placement and specialized sealing systems that create comprehensive barriers against environmental intrusion.

Durability and Longevity Considerations

The lifespan expectations for outdoor electronic installations often exceed fifteen to twenty years, making durability a paramount concern. Standard enclosures frequently exhibit premature failure due to corrosion, seal degradation, and structural weakness under environmental stress. Custom sheet metal fabrication enables the integration of corrosion-resistant alloys and protective coatings that significantly extend operational life.

Maintenance accessibility becomes crucial for long-term installations, requiring cabinet designs that facilitate service without compromising environmental protection. Custom fabrication processes accommodate specialized hinges, gasket systems, and access panels that maintain weatherproof integrity while enabling efficient maintenance procedures. This design flexibility reduces total cost of ownership through minimized service requirements and extended equipment life.

Material Selection and Manufacturing Advantages

Advanced Alloy Options

The material palette available through custom sheet metal fabrication extends far beyond standard steel and aluminum offerings. Specialized alloys incorporating chromium, nickel, and other corrosion-resistant elements provide superior performance in challenging outdoor environments. These advanced materials maintain structural properties while resisting oxidation and chemical degradation from atmospheric pollutants.

Thickness optimization becomes possible through custom fabrication processes, allowing engineers to specify material gauges that balance weight, cost, and protection requirements. Strategic thickness variations within a single enclosure enable efficient material utilization while maintaining structural integrity at critical stress points. This precision approach results in cabinets that meet performance requirements without unnecessary material waste or excessive weight.

Precision Manufacturing Techniques

Modern sheet metal fabrication employs computer-controlled cutting, forming, and welding processes that achieve tolerances impossible with traditional manufacturing methods. Laser cutting technology enables complex geometries and precise openings for connectors, ventilation, and mounting hardware. These capabilities ensure perfect component fit and eliminate gaps that could compromise environmental sealing.

Welding techniques specific to outdoor applications create seamless joints that resist moisture infiltration and provide superior structural strength. Automated welding processes ensure consistent quality while minimizing heat-affected zones that could compromise material properties. Post-weld treatments including stress relieving and surface preparation optimize the final product for outdoor service conditions.

Design Flexibility and Customization Benefits

Tailored Dimensional Requirements

Standard enclosure sizes rarely align perfectly with equipment dimensions and installation constraints, leading to inefficient space utilization and compromised protection. Custom sheet metal fabrication eliminates these limitations by enabling precise dimensional control that optimizes internal volume while minimizing external footprint. This flexibility proves particularly valuable in space-constrained installations where every inch matters.

Integration of mounting systems becomes seamless through custom fabrication approaches that incorporate equipment-specific brackets and support structures directly into the cabinet design. This integrated approach eliminates the need for secondary mounting hardware while ensuring optimal load distribution and vibration resistance. The result is a more robust and reliable installation that maintains equipment alignment under environmental stress.

Functional Feature Integration

Ventilation requirements vary significantly based on equipment heat generation and ambient conditions, necessitating customized airflow solutions. Custom sheet metal fabrication enables the integration of louvers, fans, and heat exchangers in optimal locations that maximize cooling efficiency while maintaining environmental protection. Strategic vent placement prevents moisture ingress while enabling adequate thermal management.

Cable management systems benefit tremendously from custom fabrication approaches that create organized pathways for power, data, and control connections. Integrated cable glands, strain reliefs, and routing channels eliminate the need for field modifications that could compromise cabinet integrity. This systematic approach reduces installation time while ensuring long-term reliability of electrical connections.

Quality Control and Testing Standards

Environmental Testing Protocols

Comprehensive testing validates custom sheet metal fabrication quality through rigorous environmental simulation procedures. Salt spray testing evaluates corrosion resistance over extended exposure periods, ensuring that protective coatings and material selections meet or exceed specified service life requirements. Thermal cycling tests verify structural integrity and seal performance across anticipated temperature ranges.

Ingress protection testing confirms that custom-fabricated cabinets meet specified IP ratings for dust and moisture exclusion. These standardized tests provide quantitative validation of environmental sealing effectiveness, giving end users confidence in long-term performance. Independent testing laboratories often conduct these evaluations to ensure unbiased results and regulatory compliance.

Manufacturing Quality Assurance

Quality control processes throughout custom sheet metal fabrication include dimensional verification, weld inspection, and surface finish evaluation. Coordinate measuring machines verify critical dimensions to ensure proper fit and function of integrated components. Weld penetration testing confirms joint integrity that will withstand mechanical and thermal stress over the service life.

Surface preparation and coating application receive particular attention in outdoor cabinet fabrication due to their critical role in corrosion prevention. Thickness measurements and adhesion testing verify that protective finishes meet specification requirements. These quality measures ensure consistent performance across production runs and minimize field failures due to manufacturing defects.

Cost-Effectiveness and Return on Investment

Initial Investment Considerations

While custom sheet metal fabrication typically requires higher initial investment compared to standard enclosures, the total cost analysis often favors custom solutions. Reduced maintenance requirements, extended service life, and improved equipment protection translate into significant long-term savings. The elimination of premature replacements and emergency repairs provides predictable operating costs over the installation lifecycle.

Bulk ordering opportunities for multiple installations can significantly reduce per-unit costs for custom fabricated cabinets. Standardization of custom designs across an organization enables economies of scale while maintaining application-specific optimization. This approach combines the benefits of customization with the cost advantages of volume production.

Operational Efficiency Benefits

Custom designed cabinets typically require less frequent service intervals due to superior environmental protection and component integration. Reduced service calls translate directly to lower operational costs and improved system uptime. The improved accessibility features commonly incorporated in custom designs also reduce service time when maintenance is required.

Equipment longevity increases significantly when housed in properly designed custom enclosures, delaying expensive replacements and upgrades. The protection against environmental damage and theft often reduces insurance costs and warranty claims. These factors combine to create compelling return on investment scenarios that justify the initial custom fabrication investment.

FAQ

What is the typical lead time for custom sheet metal fabrication outdoor cabinets

Lead times for custom sheet metal fabrication typically range from 4 to 8 weeks depending on complexity and current production schedules. Rush orders may be accommodated with expedited processing, though this usually involves additional costs. Design approval and material procurement often represent the longest portions of the timeline, making early collaboration essential for meeting project deadlines.

How do custom fabricated cabinets compare to standard enclosures in terms of durability

Custom fabricated cabinets generally demonstrate superior durability due to optimized material selection, precision manufacturing, and application-specific design features. Standard enclosures often represent compromises in material quality and construction methods to achieve broad market appeal and lower costs. The targeted approach of custom fabrication eliminates these compromises while addressing specific environmental challenges.

What certifications and standards apply to custom outdoor cabinet fabrication

Common standards include IP ratings for ingress protection, NEMA enclosure classifications, and various industry-specific certifications such as UL listings for electrical applications. Custom fabricators typically maintain quality management certifications like ISO 9001 to ensure consistent manufacturing processes. Compliance with local building codes and environmental regulations also influences design and material selection.

Can existing installations be upgraded with custom fabricated replacement cabinets

Retrofit applications represent excellent opportunities for custom sheet metal fabrication, as existing mounting points and infrastructure constraints can be precisely accommodated. Custom fabricators can often improve upon original designs while maintaining compatibility with existing installations. This approach enables performance upgrades without extensive site modifications or equipment replacement.

Table of Contents

- Understanding the Environmental Challenges for Outdoor Cabinets

- Material Selection and Manufacturing Advantages

- Design Flexibility and Customization Benefits

- Quality Control and Testing Standards

- Cost-Effectiveness and Return on Investment

-

FAQ

- What is the typical lead time for custom sheet metal fabrication outdoor cabinets

- How do custom fabricated cabinets compare to standard enclosures in terms of durability

- What certifications and standards apply to custom outdoor cabinet fabrication

- Can existing installations be upgraded with custom fabricated replacement cabinets