Selecting the right projector cabinet for outdoor applications requires careful consideration of environmental factors, protection levels, and operational requirements. Professional installations in parks, stadiums, amphitheaters, and commercial outdoor venues demand robust enclosures that can withstand harsh weather conditions while maintaining optimal projector performance. The decision involves evaluating multiple technical specifications, environmental ratings, and long-term durability factors that directly impact the success of your outdoor projection system.

Understanding the specific challenges of outdoor projection environments is fundamental to making an informed cabinet selection. Temperature fluctuations, moisture exposure, dust infiltration, and UV radiation can severely compromise projector functionality and lifespan. Professional-grade cabinets must provide comprehensive protection against these elements while ensuring adequate ventilation and thermal management. The investment in a quality enclosure system typically pays for itself through reduced maintenance costs, extended equipment life, and improved operational reliability.

Environmental Protection Standards and Requirements

Weather Resistance and Sealing Technologies

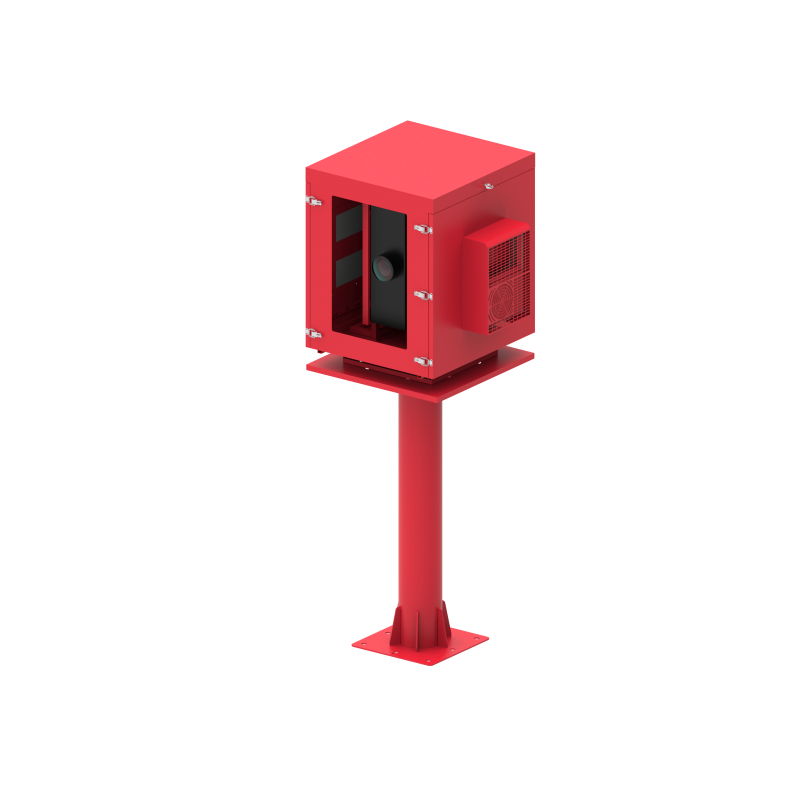

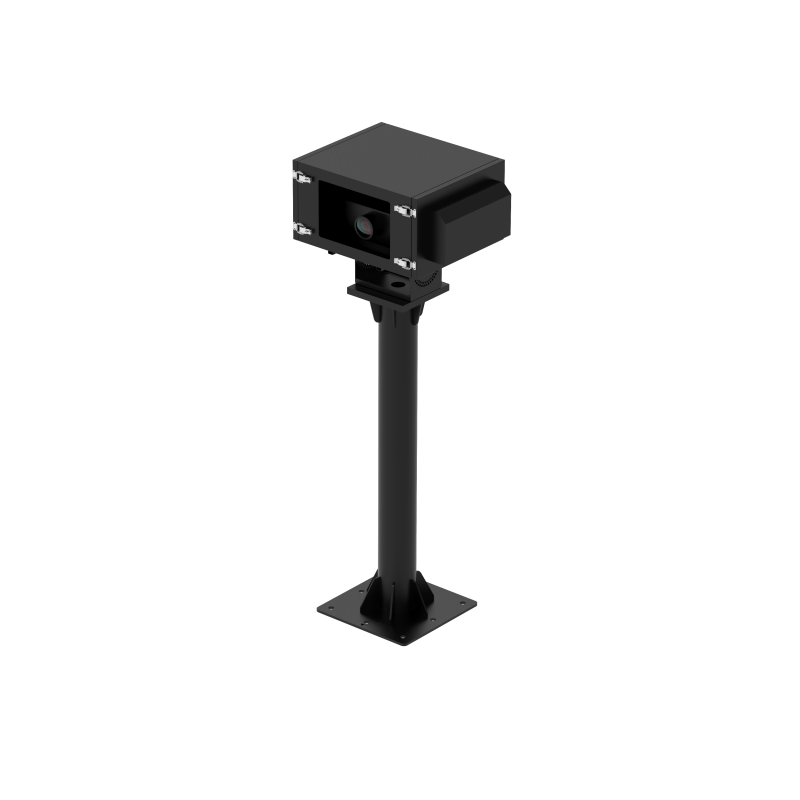

Modern projector cabinets utilize advanced sealing systems to prevent water ingress and maintain internal environmental conditions. IP65 and IP66 ratings represent industry standards for outdoor electronics protection, ensuring complete dust sealing and protection against powerful water jets from any direction. These ratings guarantee that your projector remains functional during heavy rain, snow, and extreme weather events common in outdoor installations.

Gasket materials and sealing mechanisms vary significantly between manufacturers, with premium cabinets employing multi-stage sealing systems. Compression gaskets, weatherstripping, and specialized door mechanisms work together to create hermetic barriers against environmental contamination. Regular inspection and maintenance of these sealing components ensure long-term protection effectiveness and prevent gradual deterioration that could compromise internal conditions.

Temperature Control and Thermal Management

Effective thermal management prevents overheating and condensation formation that can damage sensitive projector components. Quality enclosures incorporate active cooling systems with redundant fans, temperature sensors, and automated control systems that maintain optimal operating temperatures. These systems must operate reliably across seasonal temperature variations while consuming minimal power to ensure energy efficiency.

Insulation properties of cabinet materials significantly impact thermal performance and energy consumption. Double-wall construction with thermal barriers reduces heat transfer and minimizes the cooling load on internal climate control systems. Some advanced cabinets feature smart thermal management that adjusts cooling intensity based on ambient conditions and projector heat output, optimizing performance while extending component lifespan.

Material Construction and Durability Factors

Structural Materials and Corrosion Resistance

Cabinet construction materials directly influence longevity and maintenance requirements in outdoor environments. Marine-grade aluminum and stainless steel offer superior corrosion resistance compared to standard steel enclosures, particularly in coastal areas with high salt exposure. Powder coating and specialized surface treatments provide additional protection against UV degradation and chemical exposure that can compromise structural integrity over time.

Composite materials and reinforced plastics represent emerging alternatives that combine lightweight properties with excellent environmental resistance. These materials resist corrosion, provide natural insulation properties, and often require less maintenance than metal enclosures. However, structural strength and thermal expansion characteristics must be carefully evaluated for specific installation requirements and environmental conditions.

Security Features and Access Control

Outdoor installations require robust security measures to prevent theft and unauthorized access to expensive projection equipment. Multi-point locking systems, tamper-evident fasteners, and reinforced construction deter criminal activity while maintaining accessibility for authorized maintenance personnel. Some cabinets incorporate electronic access controls with audit trails and remote monitoring capabilities for enhanced security management.

Physical security considerations extend beyond simple locks to include mounting systems and installation methods. Permanent mounting solutions with concealed fasteners and anti-vandalism features protect both the cabinet and projector from damage or removal. Integration with facility security systems through alarm contacts and surveillance mounting points provides comprehensive protection for high-value installations.

Cooling and Ventilation System Design

Airflow Management and Filtration

Proper airflow design ensures adequate heat dissipation while preventing contamination from entering the projector compartment. Filtered ventilation systems remove dust, pollen, and other airborne particles that can accumulate on optical components and reduce image quality. High-efficiency particulate air filters combined with positive pressure systems maintain clean internal environments even in dusty outdoor locations.

Computational fluid dynamics modeling helps optimize internal airflow patterns to eliminate hot spots and ensure uniform temperature distribution. Strategic placement of intake and exhaust vents, combined with internal baffles and air directors, creates efficient cooling without compromising environmental sealing. Regular filter maintenance schedules are essential for maintaining optimal performance and preventing system overloading due to restricted airflow.

Redundancy and Fail-Safe Systems

Professional outdoor installations require redundant cooling systems to prevent projector damage during component failures. Dual fan configurations with automatic switchover capabilities ensure continuous operation even when primary cooling components malfunction. Temperature monitoring systems with adjustable alarm thresholds provide early warning of potential issues before critical temperatures are reached.

Emergency shutdown protocols protect valuable projector equipment when cooling systems fail completely. Automated power cutoff systems prevent thermal damage by safely shutting down projection equipment when internal temperatures exceed safe operating limits. These fail-safe mechanisms must balance equipment protection with operational continuity requirements to minimize service disruptions.

Power Management and Electrical Integration

Power Distribution and Surge Protection

Integrated power management systems simplify installation and provide comprehensive electrical protection for outdoor projector installations. Built-in surge suppressors, power conditioning equipment, and isolation transformers protect sensitive electronics from power quality issues common in outdoor electrical systems. These components must be sized appropriately for the total electrical load including projectors, cooling systems, and auxiliary equipment.

Remote power monitoring capabilities allow facility managers to track energy consumption and identify potential electrical issues before they cause equipment failures. Smart power management systems can schedule projector operation, implement energy-saving modes, and provide detailed usage reports for maintenance planning and cost analysis. Integration with building management systems enables centralized control and monitoring of multiple outdoor projection installations.

Cable Management and Connectivity

Professional cable management systems protect signal and power connections from environmental damage while maintaining accessibility for maintenance. Sealed cable entry systems with strain relief prevent water ingress and mechanical damage to critical connections. Multiple cable entry points accommodate various installation configurations and future expansion requirements without compromising environmental protection.

When selecting an outdoor projector enclosure, consider the specific connectivity requirements for your installation including video signals, control systems, and network connections. Fiber optic connections often provide superior performance for long cable runs common in outdoor installations, while copper connections may be more cost-effective for shorter distances. Proper grounding and electrical isolation prevent ground loops and electrical interference that can degrade signal quality.

Installation Considerations and Mounting Solutions

Structural Requirements and Load Analysis

Proper structural analysis ensures safe installation and prevents failures that could damage equipment or create safety hazards. Wind loading calculations must account for cabinet dimensions, local weather patterns, and mounting height to determine appropriate structural reinforcement requirements. Engineering certifications and compliance with local building codes are essential for permanent installations in commercial and public venues.

Foundation requirements vary significantly based on cabinet size, mounting method, and soil conditions. Concrete pads, steel posts, and building-mounted systems each have specific design requirements that must be evaluated by qualified structural engineers. Seismic considerations may require additional reinforcement in earthquake-prone regions to prevent structural failure during ground motion events.

Accessibility and Maintenance Planning

Maintenance accessibility directly impacts long-term operational costs and system reliability. Cabinet designs should provide easy access to projectors, filters, and internal components without requiring specialized tools or extensive disassembly. Hinged doors, removable panels, and slide-out mounting systems simplify routine maintenance tasks and reduce service time requirements.

Service clearances around installed cabinets must accommodate maintenance equipment and personnel safety requirements. Local codes may specify minimum clearances for electrical equipment access, while practical considerations include space for projector removal and replacement. Planning for future equipment upgrades during initial installation prevents accessibility issues that could complicate system modifications.

Cost Analysis and Return on Investment

Initial Investment Versus Long-Term Value

Quality outdoor projector enclosures represent significant initial investments but provide substantial long-term value through equipment protection and operational reliability. Comparing total cost of ownership over expected system lifespans reveals the economic benefits of premium enclosure systems. Reduced maintenance costs, extended projector life, and improved uptime typically justify higher initial expenditures for quality protection systems.

Warranty coverage and manufacturer support significantly impact total ownership costs and should be carefully evaluated during selection processes. Comprehensive warranties covering both materials and workmanship provide financial protection against manufacturing defects and premature failures. Technical support availability and local service capabilities ensure prompt resolution of issues that could otherwise result in extended downtime and revenue losses.

Energy Efficiency and Operating Costs

Energy consumption for cooling and climate control systems represents ongoing operational expenses that accumulate over system lifespans. Efficient designs with optimized thermal management reduce power consumption while maintaining necessary environmental protection. Variable speed fans, smart controllers, and high-efficiency components minimize energy costs without compromising performance or reliability.

Preventive maintenance programs extend equipment life and reduce unexpected repair costs by identifying potential issues before they cause failures. Regular filter changes, seal inspections, and performance monitoring maintain optimal system operation while preventing minor issues from developing into major problems. Documenting maintenance activities and tracking performance trends helps optimize service intervals and identify improvement opportunities.

FAQ

What IP rating should I look for in an outdoor projector cabinet

For outdoor projector installations, look for cabinets with IP65 or IP66 ratings. IP65 provides complete dust protection and protection against water jets from any direction, while IP66 offers protection against powerful water jets and heavy seas. These ratings ensure your projector remains protected during severe weather conditions including heavy rain, snow, and dust storms common in outdoor environments.

How important is active cooling versus passive cooling systems

Active cooling systems are essential for most outdoor projector installations, especially in warm climates or during summer months. While passive cooling may work in mild conditions, active systems with fans and temperature controls provide consistent performance across varying ambient temperatures. They also prevent overheating during high-brightness operation and extend projector lamp life significantly compared to passive systems.

Can I retrofit an existing projector for outdoor use with an enclosure

Most indoor projectors can be successfully adapted for outdoor use with appropriate enclosure systems. However, you must ensure the cabinet provides adequate cooling, environmental protection, and proper ventilation for your specific projector model. Some projectors may require additional modifications such as extended warranties, specialized filters, or upgraded cooling systems to maintain reliability in outdoor environments.

What maintenance schedule should I follow for outdoor projector enclosures

Typical maintenance schedules include monthly filter inspections, quarterly seal checks, and semi-annual deep cleaning of cooling systems. In harsh environments with high dust or salt exposure, more frequent maintenance may be necessary. Annual professional inspections should verify structural integrity, electrical connections, and overall system performance to prevent issues that could lead to equipment damage or safety hazards.