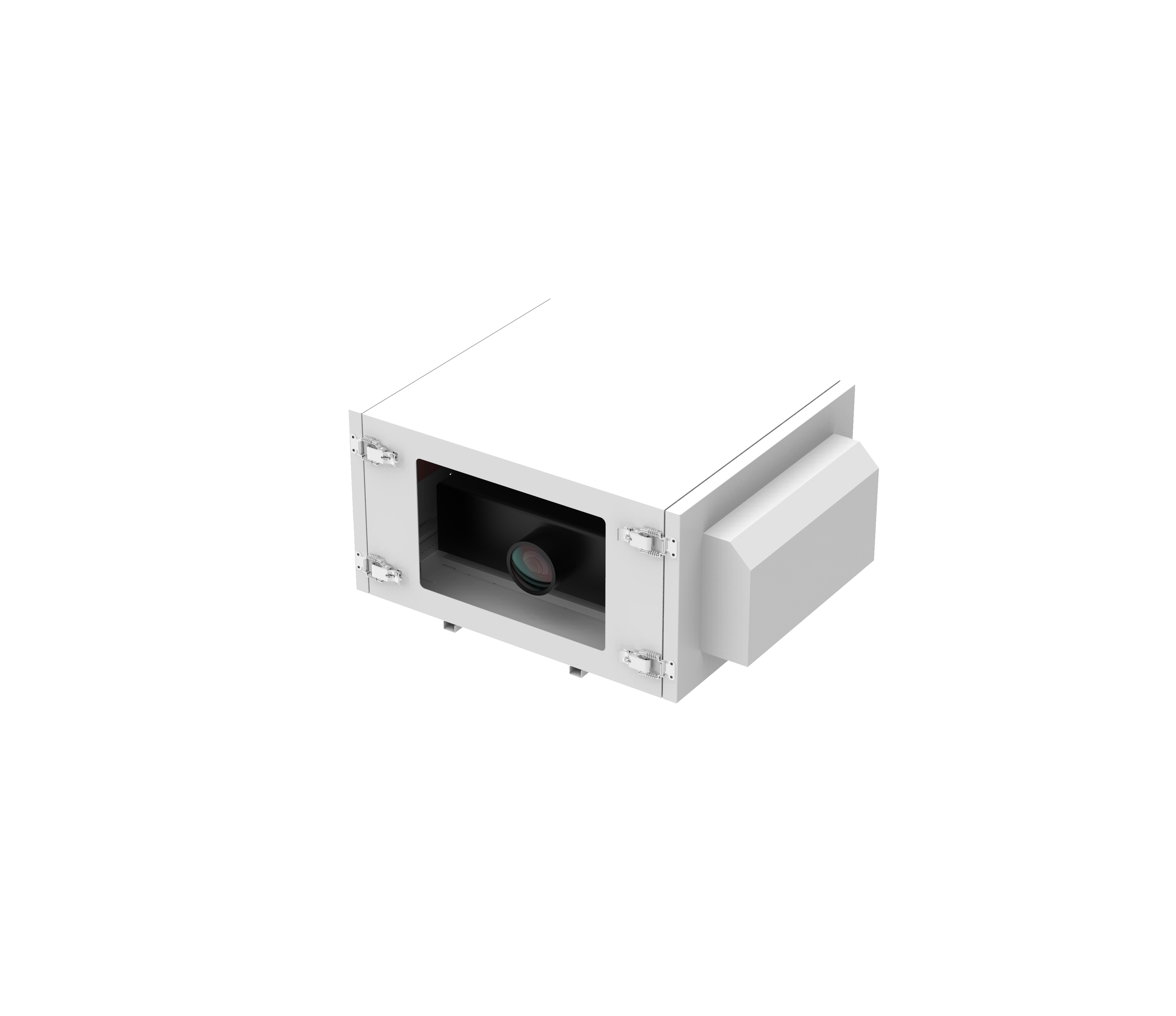

The demand for high-quality outdoor projection systems has surged dramatically as businesses, entertainment venues, and public institutions seek to deliver exceptional visual experiences in challenging environmental conditions. At the heart of these robust projection solutions lies a critical component that often determines the success or failure of outdoor installations: the outdoor projector chassis. This specialized housing system serves as the protective barrier between sensitive projection equipment and the harsh realities of outdoor environments, including temperature fluctuations, moisture, dust, and other environmental threats that can compromise equipment performance and longevity.

Modern outdoor projection applications span across diverse sectors, from large-scale advertising displays and stadium installations to architectural mapping and outdoor cinema experiences. Each application presents unique challenges that require sophisticated engineering solutions to ensure reliable operation regardless of weather conditions. The evolution of outdoor projector chassis technology has been driven by the increasing sophistication of projection equipment and the growing expectations for uninterrupted performance in demanding environments.

Understanding the fundamental principles behind advanced weatherproof design becomes essential for anyone involved in outdoor projection projects, whether as system integrators, facility managers, or technology decision-makers. The complexity of modern outdoor projector chassis extends far beyond simple weather protection, incorporating advanced thermal management, intelligent environmental controls, and robust mechanical engineering to create comprehensive protection systems that maintain optimal operating conditions for sensitive projection equipment.

Environmental Challenges Facing Outdoor Projection Systems

Temperature Extremes and Thermal Cycling

Outdoor projection systems must withstand dramatic temperature variations that can range from sub-zero conditions in winter climates to extreme heat during summer months. These temperature fluctuations create significant challenges for projection equipment, as electronic components are designed to operate within specific temperature ranges. Thermal cycling, the repeated expansion and contraction of materials due to temperature changes, can cause mechanical stress, component failure, and degradation of optical elements over time.

The impact of temperature extremes extends beyond immediate operational concerns, affecting the long-term reliability and performance characteristics of projection systems. High temperatures can accelerate the aging of electronic components, reduce lamp life, and cause thermal shutdown conditions that interrupt operation. Conversely, extremely low temperatures can affect LCD panel performance, cause condensation issues, and impact the viscosity of cooling fluids in advanced thermal management systems.

Professional outdoor projector chassis address these challenges through sophisticated thermal management strategies that maintain stable internal temperatures regardless of external conditions. These systems incorporate multiple layers of thermal protection, including active cooling systems, thermal barriers, and intelligent temperature monitoring that adjusts operational parameters based on environmental conditions.

Moisture and Humidity Control

Moisture represents one of the most persistent and damaging threats to outdoor projection equipment, manifesting in various forms including direct precipitation, humidity, condensation, and fog. Water ingress can cause immediate equipment failure through short circuits, corrosion of electrical contacts, and degradation of optical surfaces. Even minor moisture infiltration can lead to internal condensation that fogs optical elements and creates long-term reliability issues.

The challenge of moisture control extends beyond simple waterproofing, requiring comprehensive humidity management systems that maintain optimal internal conditions while preventing condensation formation. Rapid temperature changes can create conditions where warm, humid air inside the chassis comes into contact with cooler surfaces, leading to condensation that can damage sensitive components.

Advanced weatherproof designs incorporate multiple moisture management strategies, including hermetic sealing systems, desiccant materials, active dehumidification, and positive pressure systems that prevent moisture infiltration. These integrated approaches ensure that internal humidity levels remain within acceptable ranges while preventing the accumulation of moisture that could compromise system performance.

Dust and Particulate Contamination

Airborne particulates present significant challenges for outdoor projection systems, as dust accumulation can block cooling vents, contaminate optical surfaces, and interfere with mechanical components. The impact of dust contamination is particularly pronounced in projection systems due to their reliance on precise optical alignment and effective thermal management through airflow systems.

Different environments present varying levels of particulate contamination, from fine sand particles in desert climates to industrial pollutants in urban settings. Each type of contamination requires specific protection strategies, as particle size, composition, and concentration affect the design requirements for filtration and sealing systems.

Professional outdoor projector chassis incorporate advanced filtration systems, sealed optical paths, and positive pressure designs that prevent particulate infiltration while maintaining necessary airflow for thermal management. These systems balance the competing requirements of environmental protection and thermal performance through carefully engineered airflow designs and high-efficiency filtration technologies.

Advanced Weatherproof Design Principles

IP Rating Standards and Compliance

The International Protection (IP) rating system provides a standardized framework for evaluating the level of protection provided by electrical enclosures against environmental intrusion. For outdoor projection applications, IP65 and IP66 ratings represent the minimum standards for reliable operation, indicating complete protection against dust ingress and protection against water jets from any direction.

Understanding IP ratings becomes crucial when specifying outdoor projector chassis, as different applications may require varying levels of protection based on environmental exposure. Higher IP ratings, such as IP67 or IP68, provide protection against temporary submersion, which may be necessary for installations in flood-prone areas or marine environments.

Achieving and maintaining IP-rated protection requires careful attention to sealing technologies, cable entry systems, and maintenance access points. Professional chassis designs incorporate redundant sealing systems, quality gasket materials, and testing procedures that verify protection levels throughout the product lifecycle.

Material Selection and Corrosion Resistance

The selection of materials for outdoor projector chassis construction plays a critical role in long-term durability and environmental resistance. Aluminum alloys treated with anodizing or powder coating provide excellent corrosion resistance while maintaining favorable thermal properties for heat dissipation. Stainless steel components offer superior corrosion resistance in marine or chemical environments but require careful thermal management due to their lower thermal conductivity.

Advanced composite materials are increasingly used in specialized applications where weight reduction, thermal insulation, or specific environmental resistance properties are required. These materials must be carefully evaluated for UV stability, thermal expansion characteristics, and long-term durability under cyclical environmental stress.

The selection of gasket and sealing materials requires equal attention, as these components often represent the weakest link in weatherproof designs. Silicone, EPDM, and specialized fluorocarbon elastomers offer different performance characteristics for temperature resistance, chemical compatibility, and long-term sealing effectiveness.

Thermal Management Integration

Effective thermal management represents one of the most complex aspects of outdoor projector chassis design, requiring the integration of passive and active cooling systems that maintain optimal operating temperatures while preserving environmental protection. The challenge lies in balancing the need for heat dissipation with the requirement for sealed environmental protection.

Advanced thermal management systems incorporate multiple cooling technologies, including liquid cooling systems, forced air circulation, and phase-change materials that provide thermal buffering during peak load conditions. These systems must be designed to operate reliably across the full range of environmental conditions while maintaining the integrity of environmental sealing systems.

Intelligent thermal management incorporates monitoring and control systems that adjust cooling performance based on real-time environmental conditions and equipment loading. These systems optimize energy efficiency while ensuring that critical temperature limits are never exceeded, even during extreme environmental conditions or equipment malfunction scenarios.

Critical Design Features for Weather Protection

Sealing Technologies and Gasket Systems

Professional sealing systems form the foundation of effective weatherproof protection, requiring careful engineering of gasket compression, sealing surface finish, and assembly procedures. Multiple sealing technologies are often combined to provide redundant protection against environmental intrusion, including primary seals for normal operation and secondary seals for extreme conditions.

Advanced gasket systems incorporate features such as drainage channels, pressure equalization, and progressive compression that adapt to thermal expansion and mechanical stress. These systems must maintain sealing effectiveness throughout multiple thermal cycles and extended exposure to UV radiation, ozone, and other environmental factors that can degrade elastomeric materials.

The design of cable entry systems represents a particular challenge, as these penetrations must provide reliable sealing while accommodating different cable types and sizes. Professional installations utilize cable glands, compression seals, and potting compounds that maintain sealing integrity while allowing for service access and cable replacement.

Ventilation and Pressure Management

Maintaining proper ventilation while preserving weatherproof protection requires sophisticated engineering solutions that balance airflow requirements with environmental sealing. Positive pressure systems create internal pressure slightly above atmospheric pressure, preventing infiltration of dust, moisture, and other contaminants while maintaining necessary airflow for thermal management.

Advanced ventilation systems incorporate filtered air intakes, exhaust systems, and pressure monitoring that ensures optimal internal conditions while preventing environmental contamination. These systems must be designed to prevent the formation of dead air spaces where moisture or contaminants could accumulate.

Pressure equalization systems address the challenges created by temperature-induced pressure changes that can stress sealing systems and create unwanted airflow patterns. Gore-Tex vents and similar technologies allow pressure equalization while maintaining protection against liquid water and particulate contamination.

Drainage and Water Management

Effective water management extends beyond simple waterproofing to include drainage systems that handle condensation, cleaning water, and any moisture that may penetrate outer sealing systems. Professional designs incorporate multiple drainage paths that prevent water accumulation while maintaining the integrity of environmental protection systems.

Condensation management requires particular attention in outdoor projector chassis that experience significant temperature variations. Internal drainage systems, desiccant materials, and controlled ventilation work together to prevent condensation formation and remove any moisture that does accumulate.

Water management systems must be designed to function reliably without maintenance intervention, as outdoor installations are often located in areas where regular service access is limited. Self-draining designs, freeze-resistant materials, and fail-safe drainage paths ensure continued protection even when primary systems are compromised.

Active Environmental Control Systems

Climate Control Integration

Advanced outdoor projector chassis increasingly incorporate active climate control systems that maintain optimal internal conditions regardless of external environmental variations. These systems combine heating, cooling, and humidity control to create stable operating environments that extend equipment life and ensure consistent performance.

Integrated climate control systems utilize sophisticated sensors and control algorithms that monitor internal and external conditions, adjusting heating, cooling, and dehumidification based on real-time requirements. These systems can anticipate environmental changes based on weather forecasting data and pre-condition internal environments to maintain stability during extreme weather events.

Energy efficiency considerations drive the design of climate control systems, incorporating variable-speed components, intelligent staging, and energy recovery systems that minimize power consumption while maintaining environmental control. These systems often include battery backup or alternative power sources to ensure continued operation during power interruptions.

Monitoring and Diagnostic Systems

Modern outdoor projector chassis incorporate comprehensive monitoring systems that track environmental conditions, equipment performance, and system health parameters. These systems provide real-time visibility into chassis conditions and can alert operators to potential issues before they impact projection system performance.

Advanced diagnostic systems utilize artificial intelligence and machine learning algorithms to predict maintenance requirements, optimize system performance, and identify developing problems based on trend analysis. These capabilities enable proactive maintenance strategies that minimize downtime and extend equipment life.

Remote monitoring capabilities allow system operators to track multiple installations from centralized locations, enabling efficient maintenance planning and rapid response to environmental challenges. Integration with building management systems and security networks provides comprehensive facility monitoring that includes projection system status as part of overall facility operations.

Installation and Maintenance Considerations

Site Assessment and Environmental Planning

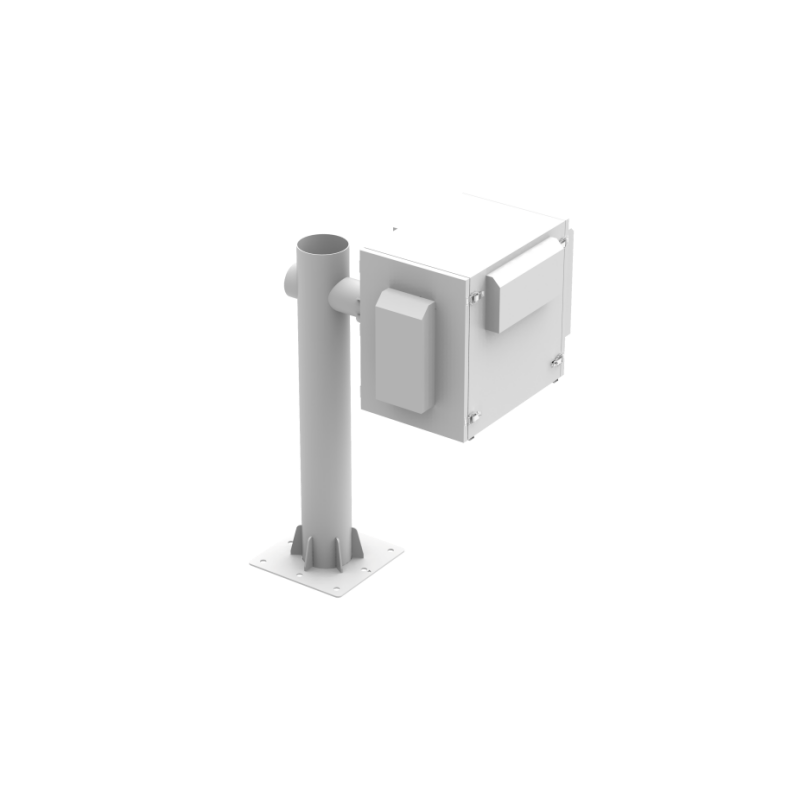

Successful outdoor projector installations begin with comprehensive site assessment that evaluates environmental conditions, exposure risks, and installation requirements. This assessment must consider seasonal variations, prevailing weather patterns, and site-specific challenges that may affect long-term system performance.

Environmental planning extends beyond immediate weather protection to include considerations such as solar exposure, wind loading, seismic requirements, and accessibility for maintenance. These factors influence chassis design specifications and installation requirements that ensure reliable long-term operation.

Professional installation planning incorporates contingency measures for extreme weather events, including temporary weather protection during installation, emergency shutdown procedures, and recovery protocols that minimize equipment damage during severe environmental conditions.

Preventive Maintenance Protocols

Maintaining weatherproof protection requires regular inspection and maintenance of sealing systems, drainage components, and environmental control systems. Professional maintenance protocols establish inspection schedules, replacement intervals, and performance testing procedures that ensure continued protection effectiveness.

Preventive maintenance must address the gradual degradation of sealing materials, accumulation of contaminants in filtration systems, and wear of mechanical components subjected to environmental stress. Regular maintenance prevents minor issues from developing into major failures that could compromise equipment protection.

Documentation and record-keeping requirements for maintenance activities provide traceability for warranty claims, regulatory compliance, and performance optimization. Digital maintenance management systems enable efficient scheduling, inventory management, and performance tracking across multiple installations.

FAQ

What IP rating is required for outdoor projector chassis in different environments

The required IP rating depends on the specific environmental conditions and exposure risks of the installation site. For most outdoor applications, IP65 provides adequate protection against dust and water jets, making it suitable for covered installations or areas with moderate weather exposure. IP66 offers enhanced protection against heavy rain and high-pressure washing, recommended for fully exposed installations. Marine environments or flood-prone areas may require IP67 or IP68 ratings that provide protection against temporary submersion. The selection should consider not only immediate environmental conditions but also seasonal variations and extreme weather events that may occur during the system's operational life.

How do active cooling systems maintain efficiency while preserving weatherproof sealing

Advanced cooling systems utilize closed-loop designs that maintain thermal management effectiveness without compromising environmental protection. Liquid cooling systems circulate coolant through sealed circuits that transfer heat from internal components to external heat exchangers, eliminating the need for large air exchanges that could compromise sealing. Air-based systems employ positive pressure designs with filtered air intakes and sealed exhaust paths that maintain cooling airflow while preventing contamination. Heat exchangers with isolated air circuits allow thermal transfer without mixing internal and external air, preserving environmental protection while maintaining cooling efficiency.

What maintenance is required to preserve weatherproof protection over time

Regular maintenance includes inspection of gasket systems for compression set, cracking, or degradation, typically performed annually or semi-annually depending on environmental exposure. Drainage systems require periodic cleaning to prevent blockages that could cause water accumulation. Filter systems need replacement based on contamination levels and airflow measurements. Sealing materials may require replacement every 3-5 years depending on environmental conditions and material specifications. Pressure testing should be performed periodically to verify continued sealing effectiveness, and any cable penetrations should be inspected for seal integrity. Documentation of all maintenance activities ensures compliance with warranty requirements and provides data for optimizing maintenance schedules.

How do environmental control systems adapt to changing weather conditions

Modern environmental control systems utilize multiple sensors that monitor internal temperature, humidity, and pressure along with external weather conditions to automatically adjust system operation. Predictive algorithms can anticipate environmental changes based on weather forecasting data and pre-condition internal environments before extreme conditions arrive. Adaptive control systems modulate heating, cooling, and dehumidification based on real-time requirements, optimizing energy efficiency while maintaining stable internal conditions. Emergency protocols activate additional protection measures during severe weather events, such as increasing positive pressure, activating backup heating systems, or implementing protective shutdown procedures when conditions exceed safe operating parameters.

Table of Contents

- Environmental Challenges Facing Outdoor Projection Systems

- Advanced Weatherproof Design Principles

- Critical Design Features for Weather Protection

- Active Environmental Control Systems

- Installation and Maintenance Considerations

-

FAQ

- What IP rating is required for outdoor projector chassis in different environments

- How do active cooling systems maintain efficiency while preserving weatherproof sealing

- What maintenance is required to preserve weatherproof protection over time

- How do environmental control systems adapt to changing weather conditions