Selecting the appropriate outdoor projector chassis is crucial for ensuring reliable performance in challenging environmental conditions. Whether you're planning a large-scale outdoor event, permanent installation at a sports venue, or creating an immersive outdoor entertainment experience, the right enclosure can make the difference between seamless operation and costly equipment failures. Modern outdoor projection systems face numerous environmental threats including temperature extremes, moisture infiltration, dust accumulation, and potential vandalism, making chassis selection a critical decision that impacts both immediate functionality and long-term operational costs.

Understanding Environmental Protection Standards

IP Rating Classifications for Outdoor Use

The Ingress Protection rating system provides standardized measurements for how well an enclosure protects against solid particles and liquids. For outdoor projector applications, understanding these classifications is essential when evaluating chassis options. IP65 ratings offer complete dust protection and resistance to water jets from any direction, making them suitable for most outdoor installations. However, environments with extreme weather conditions may require IP66 or IP67 ratings for enhanced water protection.

Different outdoor scenarios demand varying levels of protection, and selecting an inappropriate IP rating can lead to premature equipment failure. Coastal installations face salt spray challenges that require specialized coatings and sealing materials beyond standard IP ratings. Mountain environments present unique challenges with rapid temperature fluctuations and potential snow accumulation that standard ratings may not adequately address.

Temperature Range Considerations

Operating temperature ranges significantly impact projector performance and lifespan, making thermal management a primary concern when selecting an outdoor projector chassis. Most professional projectors operate optimally between 32°F and 95°F, but outdoor conditions frequently exceed these parameters. Quality chassis systems incorporate active cooling and heating elements to maintain stable internal temperatures regardless of external conditions.

Thermal cycling effects can cause component degradation over time, particularly in electronic circuits and optical elements. Advanced chassis designs include temperature monitoring systems that automatically adjust cooling or heating output based on real-time conditions. Some systems feature remote monitoring capabilities that alert operators to temperature anomalies before they cause equipment damage.

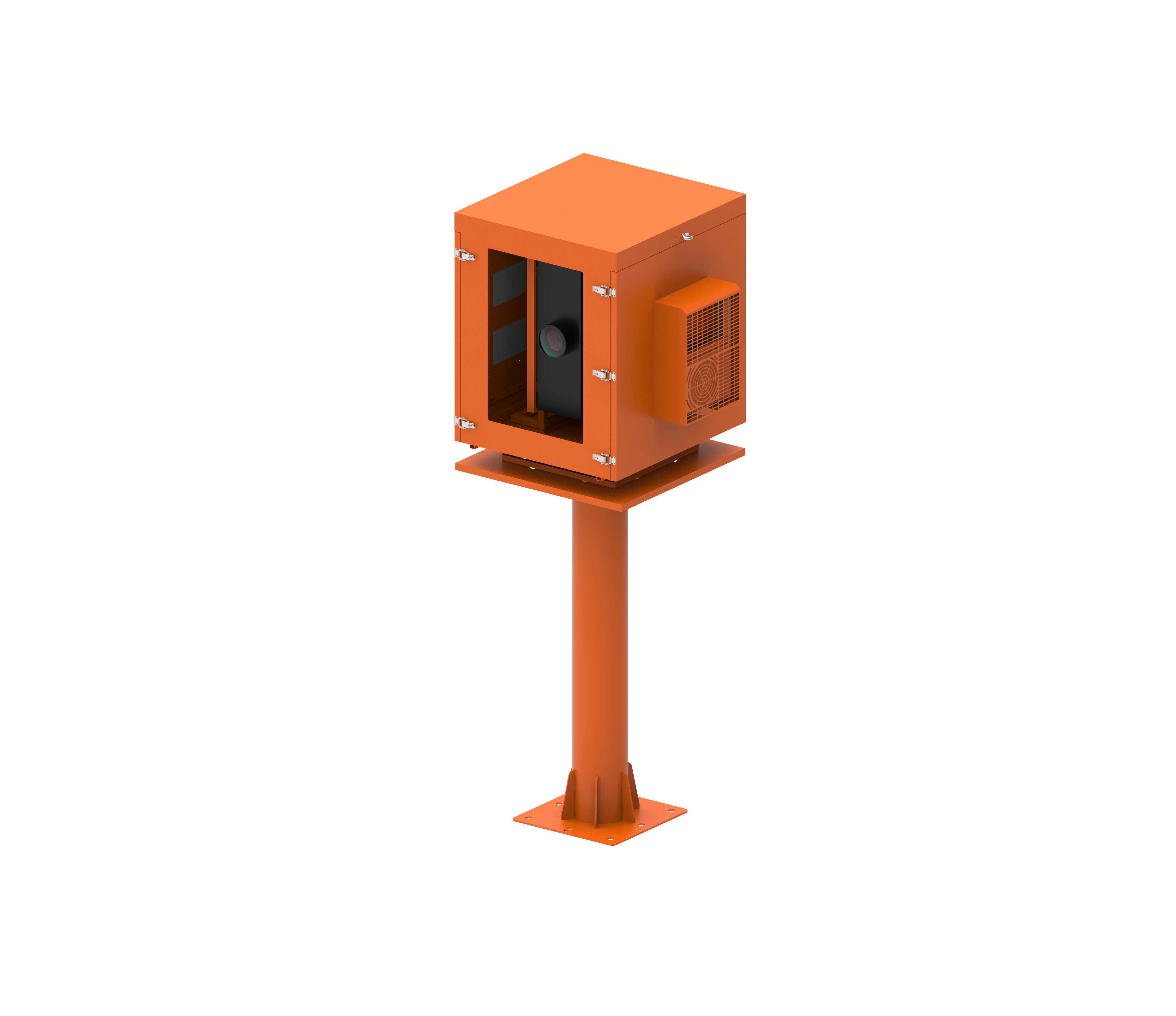

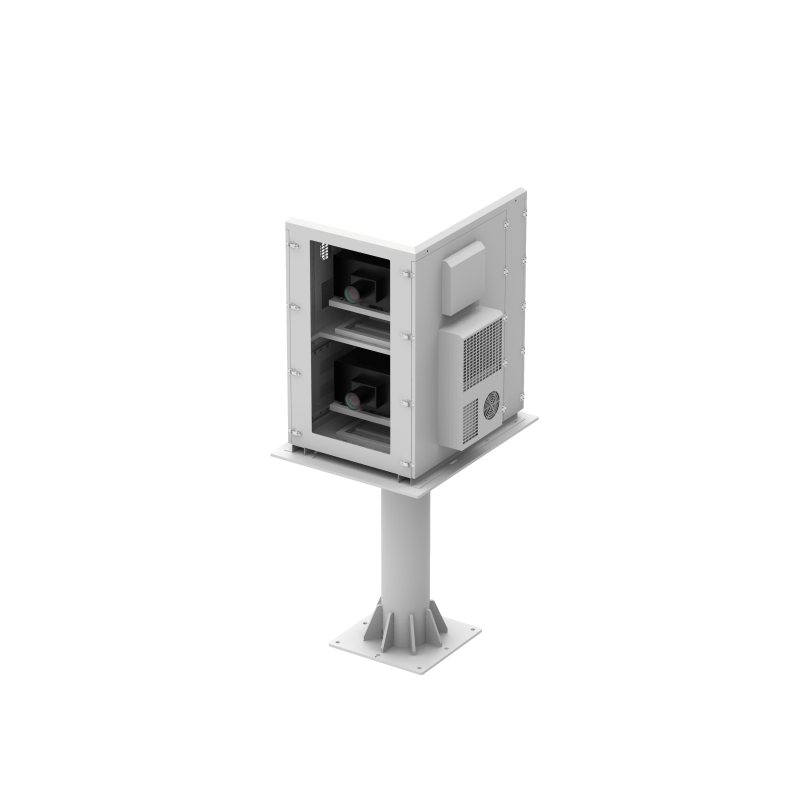

Material Selection and Construction Quality

Corrosion-Resistant Materials

Material selection directly influences the longevity and reliability of outdoor projector installations. Aluminum alloy construction offers excellent strength-to-weight ratios while providing natural corrosion resistance through oxidation. Stainless steel variants provide superior corrosion resistance but add significant weight and cost to installations. Marine-grade materials become essential for installations near saltwater environments where standard materials quickly deteriorate.

Surface treatments and coatings enhance base material performance in harsh environments. Powder coating provides durable color retention and additional corrosion protection, while anodizing treatments create hard, wear-resistant surfaces. Some manufacturers offer specialized coatings designed for specific environmental challenges such as acid rain, industrial pollutants, or extreme UV exposure.

Structural Integrity and Mounting Systems

Robust construction ensures that outdoor projector chassis can withstand wind loads, vibration, and potential impact damage throughout their operational lifespan. Wind resistance calculations become critical for installations in exposed locations, requiring chassis designs that minimize surface area while maintaining adequate ventilation. Reinforced mounting points and vibration dampening systems protect sensitive internal components from mechanical stress.

Mounting flexibility allows installations to adapt to various architectural requirements and optimal projection angles. Universal mounting systems accommodate different projector models while maintaining proper weight distribution and structural stability. Quick-release mechanisms facilitate maintenance access without compromising security or environmental protection.

Thermal Management Systems

Active Cooling Technologies

Effective thermal management extends projector lifespan and maintains consistent performance in challenging outdoor conditions. Multi-stage cooling systems typically combine intake filtration, internal air circulation, and exhaust ventilation to create optimal thermal environments. Variable-speed fans automatically adjust airflow based on internal temperature sensors, balancing cooling efficiency with energy consumption and noise levels.

Heat exchanger systems provide efficient thermal transfer without exposing internal components to external air. These sealed systems prevent dust infiltration while maintaining excellent cooling performance. Some advanced designs incorporate phase-change materials that absorb excess heat during peak operating periods and release it during cooler conditions, creating natural thermal regulation.

Heating Elements for Cold Weather Operation

Cold weather operation requires additional considerations beyond basic freeze protection, as projector lamps and electronic components perform poorly at low temperatures. Integrated heating systems maintain minimum operating temperatures while preventing condensation formation during startup cycles. Smart heating controls activate based on ambient temperature sensors and can include pre-warming cycles for scheduled operation.

Heating system efficiency impacts overall power consumption and operational costs, making energy-efficient designs increasingly important for permanent installations. Some systems utilize waste heat from projector operation to reduce external heating requirements, while others incorporate solar heating elements for remote installations without reliable power infrastructure.

Ventilation and Air Quality Management

Filtration Systems

Air quality management prevents dust accumulation and contamination that can degrade projector performance and require frequent maintenance interventions. Multi-stage filtration systems typically include coarse pre-filters for large particles, fine filters for dust prevention, and activated carbon filters for chemical contaminant removal. Filter accessibility and replacement scheduling significantly impact long-term operational costs and system reliability.

Different environments require specialized filtration approaches, with industrial locations needing enhanced chemical filtration and desert installations requiring fine dust protection systems. Some advanced chassis incorporate self-cleaning filter mechanisms that extend replacement intervals and reduce maintenance requirements. Filter monitoring systems provide alerts when replacement becomes necessary, preventing performance degradation from clogged filtration elements.

Airflow Design Optimization

Proper airflow design ensures efficient heat removal while preventing dust accumulation in critical areas. Laminar airflow patterns minimize turbulence that can cause dust settling on optical elements, while positive pressure systems prevent external contaminant infiltration. Computational fluid dynamics modeling helps optimize internal airflow patterns for maximum cooling efficiency with minimal energy consumption.

Strategic placement of intake and exhaust ports prevents recirculation of heated air while maintaining environmental protection ratings. Some designs incorporate variable airflow geometry that adapts to different operating conditions, optimizing performance for both high-heat and low-heat projection modes. Sound dampening materials reduce fan noise without impeding airflow efficiency.

Security Features and Access Control

Physical Security Measures

Outdoor installations face security risks including theft, vandalism, and unauthorized access that can compromise equipment integrity and operational continuity. Tamper-resistant locking mechanisms provide multiple security layers while maintaining emergency access capabilities for authorized personnel. Reinforced access panels and security-rated hardware deter casual tampering while facilitating legitimate maintenance activities.

Concealed mounting systems reduce visible hardware that could facilitate unauthorized removal attempts. Some chassis designs incorporate alarm systems that detect unauthorized access attempts and can integrate with existing security infrastructure. Strategic cable routing and connection protection prevent service disruption from vandalism targeting external connections.

Remote Monitoring Integration

Modern outdoor projector chassis systems frequently include remote monitoring capabilities that provide real-time status information and early warning of potential issues. Temperature sensors, humidity monitors, and vibration detectors create comprehensive environmental awareness that enables proactive maintenance scheduling. Network connectivity allows integration with building management systems and remote diagnostic capabilities.

Automated alert systems notify operators of conditions requiring attention before they cause equipment damage or performance degradation. Historical data logging helps identify patterns and optimize operational parameters for specific installation environments. Some systems include predictive maintenance algorithms that anticipate component replacement needs based on usage patterns and environmental exposure.

Installation Considerations and Best Practices

Site Preparation Requirements

Proper site preparation ensures optimal outdoor projector chassis performance and longevity through careful attention to drainage, wind exposure, and accessibility requirements. Foundation design must accommodate both static weight loads and dynamic forces from wind and vibration. Drainage considerations prevent water accumulation around mounting points and electrical connections that could compromise system integrity over time.

Utility routing planning protects power and data connections from environmental exposure while maintaining easy access for maintenance activities. Underground conduit systems provide the highest protection level but require careful installation to prevent water infiltration. Overhead routing may be more cost-effective but requires additional protection measures against weather and mechanical damage.

Maintenance Access Planning

Maintenance accessibility directly impacts operational costs and system reliability throughout the installation lifespan. Service panel placement should balance security requirements with technician access needs, considering tools and equipment required for routine maintenance tasks. Clear access pathways and adequate working space around the chassis facilitate efficient service activities and reduce labor costs.

Scheduled maintenance requirements vary based on environmental conditions and usage patterns, making maintenance planning an essential aspect of chassis selection. Systems with tool-free access panels and quick-disconnect connections reduce service time and associated costs. Some installations benefit from redundant systems that allow continued operation during maintenance activities.

Cost Analysis and Return on Investment

Initial Investment Considerations

Outdoor projector chassis costs vary significantly based on protection levels, features, and construction quality, making thorough cost analysis essential for informed decision-making. Higher initial investment in quality chassis systems typically results in lower long-term operational costs through reduced maintenance requirements and extended equipment lifespan. Custom chassis solutions may offer better value for specialized applications despite higher upfront costs.

Total cost of ownership calculations should include installation expenses, ongoing maintenance costs, energy consumption, and potential downtime costs from equipment failures. Insurance considerations may favor higher-rated protection systems that reduce risk exposure and potential claim costs. Financing options and warranty terms can significantly impact overall project economics and risk allocation.

Long-term Operational Benefits

Quality chassis systems provide measurable benefits through extended projector lifespan, reduced maintenance frequency, and improved reliability that translates to lower operational costs and higher system availability. Energy-efficient thermal management systems reduce ongoing power costs while maintaining optimal operating conditions. Preventive protection against environmental damage eliminates costly emergency repairs and equipment replacement.

Enhanced security features protect valuable projection equipment while reducing insurance costs and theft risk exposure. Remote monitoring capabilities enable predictive maintenance scheduling that minimizes unexpected downtime and associated revenue losses. Professional installations with quality chassis systems often command higher resale values and easier technology upgrade paths.

FAQ

What IP rating is recommended for outdoor projector installations?

For most outdoor projector installations, IP65 rating provides adequate protection against dust and water ingress from rain and cleaning activities. However, installations in extreme weather environments or areas prone to flooding should consider IP66 or IP67 ratings for enhanced water protection. Coastal installations may require additional corrosion protection beyond standard IP ratings due to salt spray exposure.

How important is thermal management in outdoor projector chassis?

Thermal management is critical for outdoor projector performance and longevity, as temperature extremes can cause immediate operational issues and long-term component degradation. Quality chassis systems maintain optimal internal temperatures through active cooling and heating systems, extending projector lifespan and ensuring consistent performance. Poor thermal management can lead to frequent lamp replacements, electronic component failures, and costly downtime.

What materials offer the best durability for outdoor projector enclosures?

Aluminum alloy construction provides excellent corrosion resistance and strength-to-weight ratios for most outdoor applications. Stainless steel offers superior corrosion resistance but adds weight and cost. Marine-grade materials become essential for saltwater environments, while specialized coatings enhance performance in industrial or chemically challenging locations. Material selection should match specific environmental conditions and budget constraints.

How do I determine the right size chassis for my projector?

Chassis sizing should accommodate the projector dimensions plus adequate clearance for airflow, cable connections, and maintenance access. Consider future projector upgrades when selecting chassis size, as oversized enclosures often cost less than replacement when technology changes. Universal mounting systems provide flexibility for different projector models while maintaining proper weight distribution and thermal management efficiency.